Copper powder water atomization system and atomization structure thereof

A technology of water atomization and copper powder, which is applied in the field of copper powder water atomization system and its atomization structure, can solve the problems of irregular shape of copper powder particles, low atomization efficiency, agglomeration and segregation, etc., and achieve smooth surface , Accelerate cutting efficiency and reduce particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

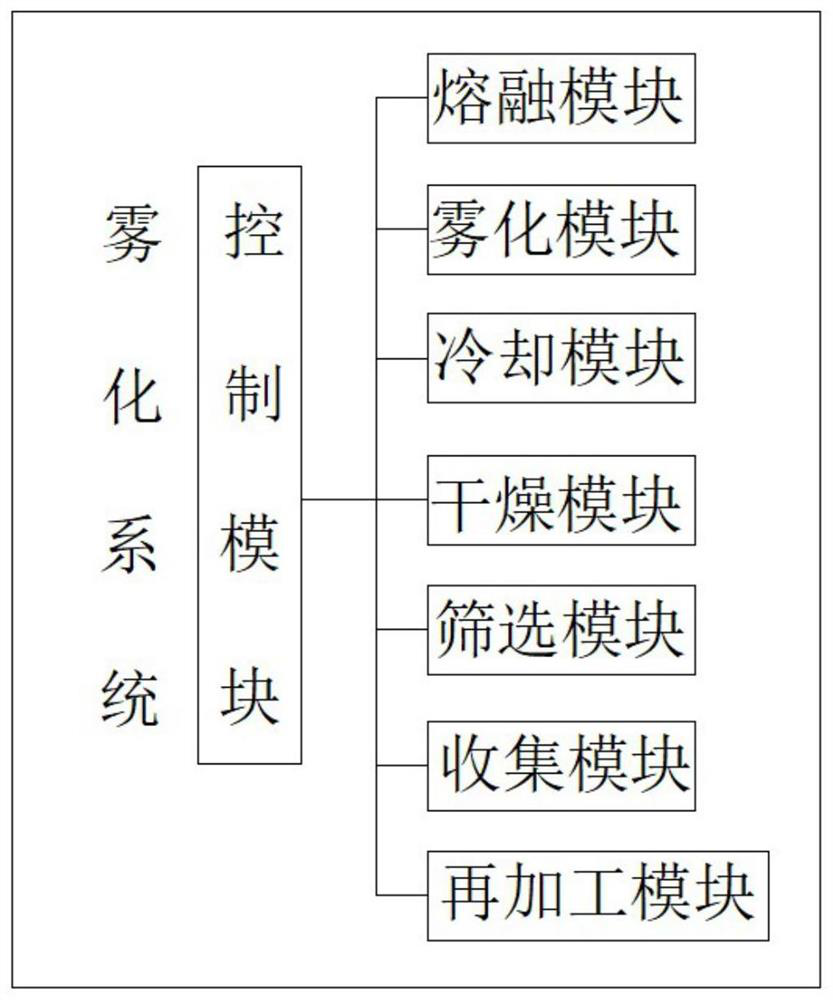

[0038] Reference figure 1 , A copper powder water atomization system, comprising: a melting module for heating and melting solid metal copper at high temperature to obtain liquid copper; a water atomization module for impacting liquid copper into copper powder; a cooling module for The copper powder is cooled; the drying module is used to dry the copper powder to remove the surface moisture of the copper powder; the screening module is used to siev the copper powder to obtain the copper powder of the target particle size; the collection module is used to remove the target Copper powder is collected; reprocessing module: used to introduce copper powder that has not reached the target particle size into the melting module for re-water atomization.

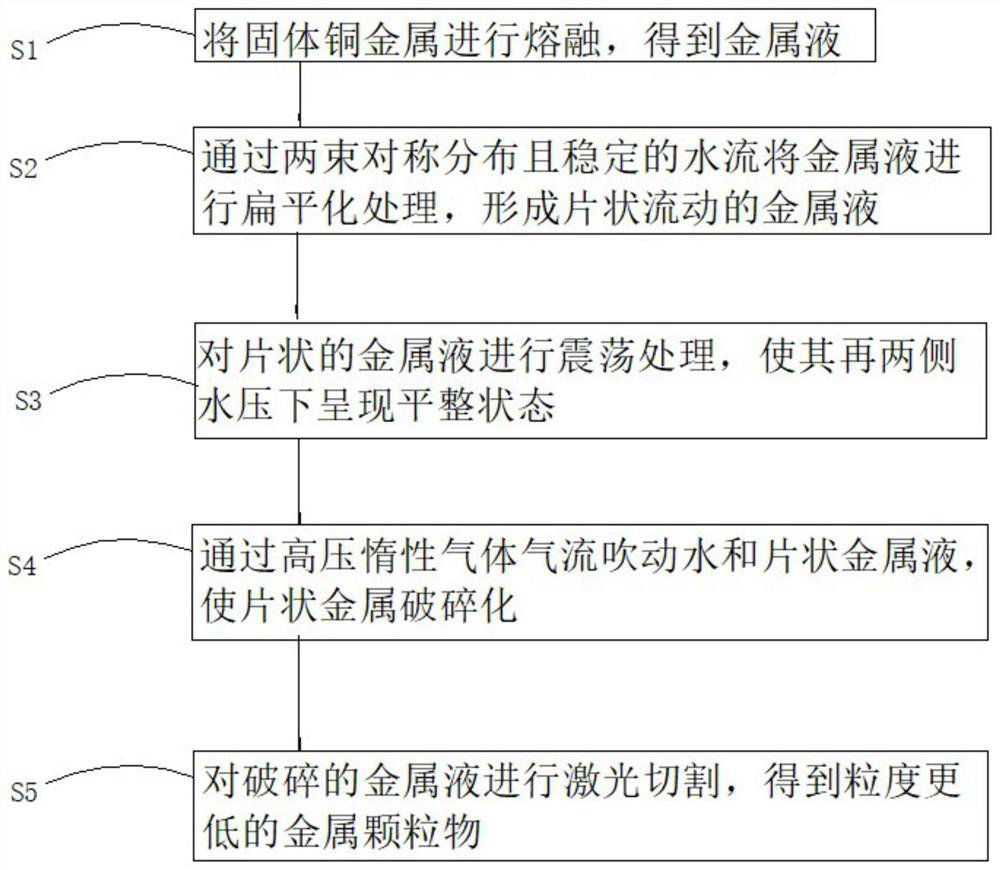

[0039] reference figure 2 , The water atomization method in the copper powder water atomization system includes the following steps:

[0040] S1: Melting solid copper metal to obtain molten metal;

[0041] S2: Flatten the molten metal thr...

Embodiment 2

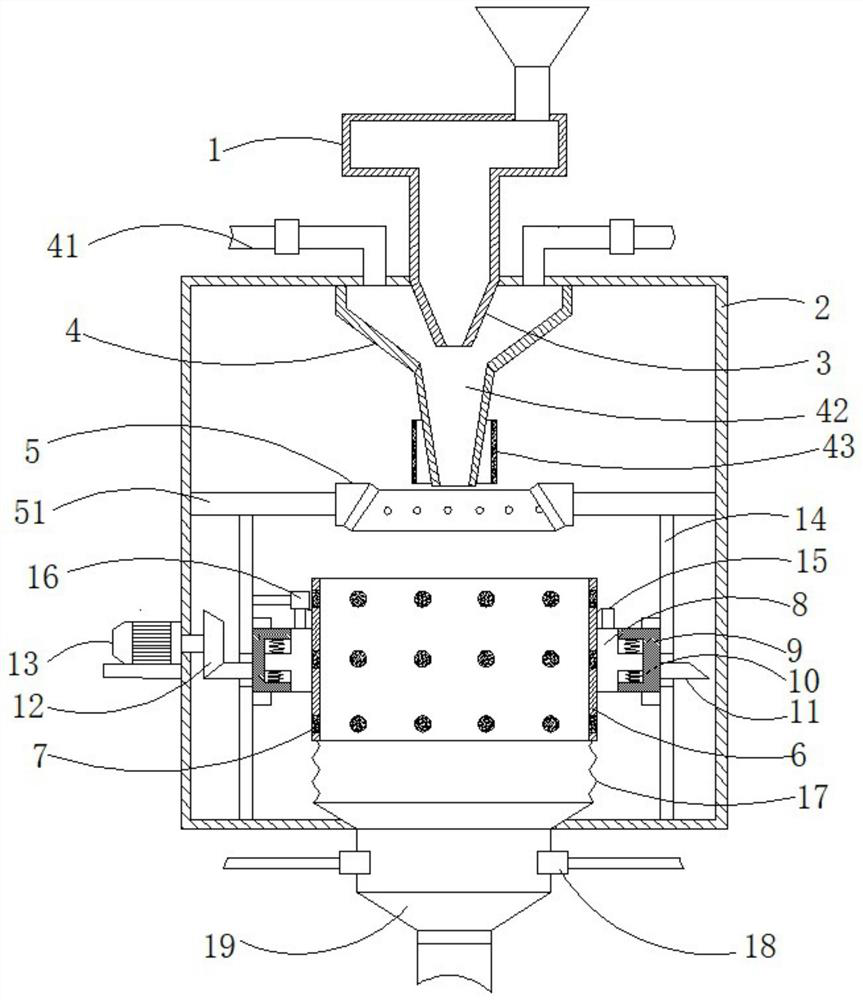

[0053] The difference from the embodiment is that the atomization structure in this embodiment also includes a cutting assembly for re-cutting the crushed metal powder. Refer to figure 1 , The cutting assembly includes a cutting cylinder 6, the cutting cylinder 6 is located below the high-pressure gas ring 5, the cutting cylinder 6 and the high-pressure gas ring 5 are arranged coaxially, and the inner wall of the cutting cylinder 6 is embedded with a plurality of laser generators. The laser generator 7 can emit laser light. The crushed metal particles move inside the cutting cylinder 6 due to gravity and high-pressure gas. The laser generator 7 cuts the crushed metal particles inside the cutting cylinder 6 again to reduce The particle size of the metal droplets enhances the atomization effect of the metal liquid.

[0054] Further, refer to figure 1 with 6 A mounting ring 8 is fixedly provided on the outer wall of the cutting cylinder 6, a rotating sleeve 9 is provided on the outsi...

Embodiment 3

[0056] The difference from Example 2 is that reference figure 1 with Figure 5 In this embodiment, the outer wall of the cutting cylinder 6 is fixedly provided with a wave ring 15, and the inner side of the spacer 14 is provided with a roller 16 rotatably connected with the spacer 14 and adapted to the wave edge of the wave ring 15; An elastic member 10 is arranged between the spline end surface and the spline groove wall of the rotating sleeve 9. While the cutting drum 6 in this embodiment is rotating, the wave ring 15 is in contact with the roller 16. Since the position of the roller 16 is fixed, the cutting drum 6 will follow the wave edge on the wave ring 15 to move up and down, which speeds up the cutting efficiency. In the example, the rotation and the up and down movement of the cutting cylinder 6 share a power source, and the structure is compact.

[0057] In this embodiment, in order to cooperate with the up and down movement of the cutting barrel 6, an annular telescopi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com