Preparation method of silencing microporous artistic decorative ceramic tile

An artistic and microporous technology, applied in the field of porous ceramic materials, can solve the problems of uneven distribution of pore size and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

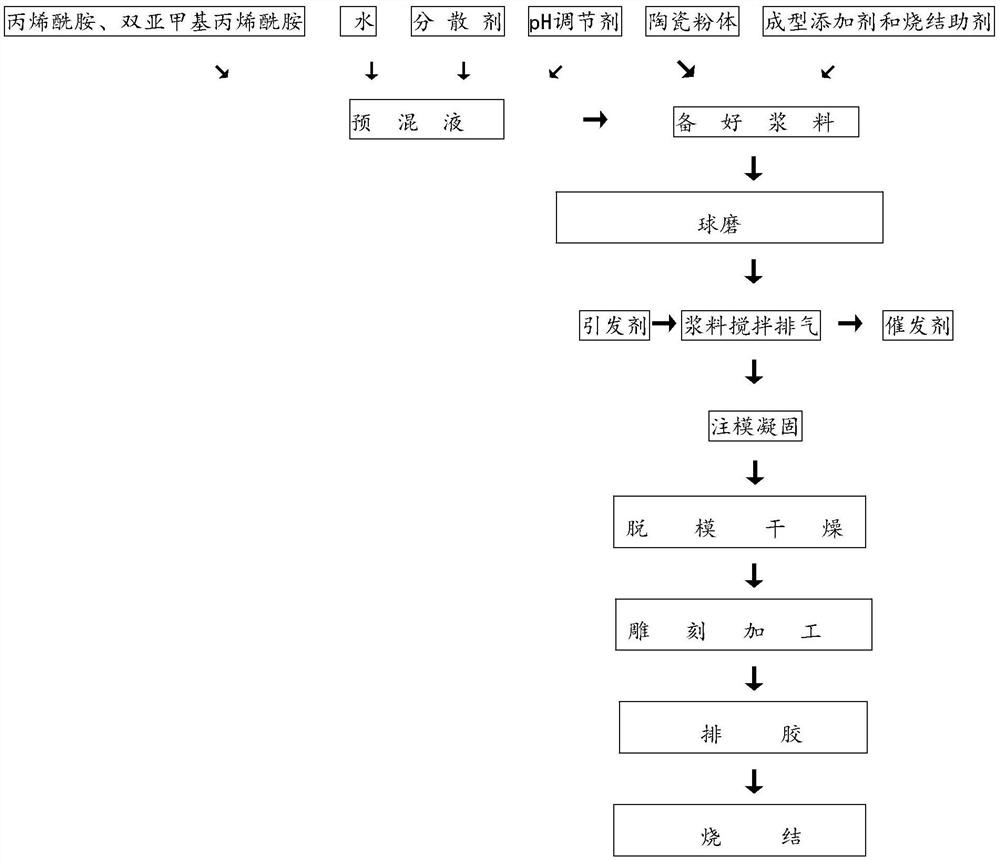

[0023] The invention provides a method for preparing sound-absorbing microporous art decorative tiles, comprising the following steps:

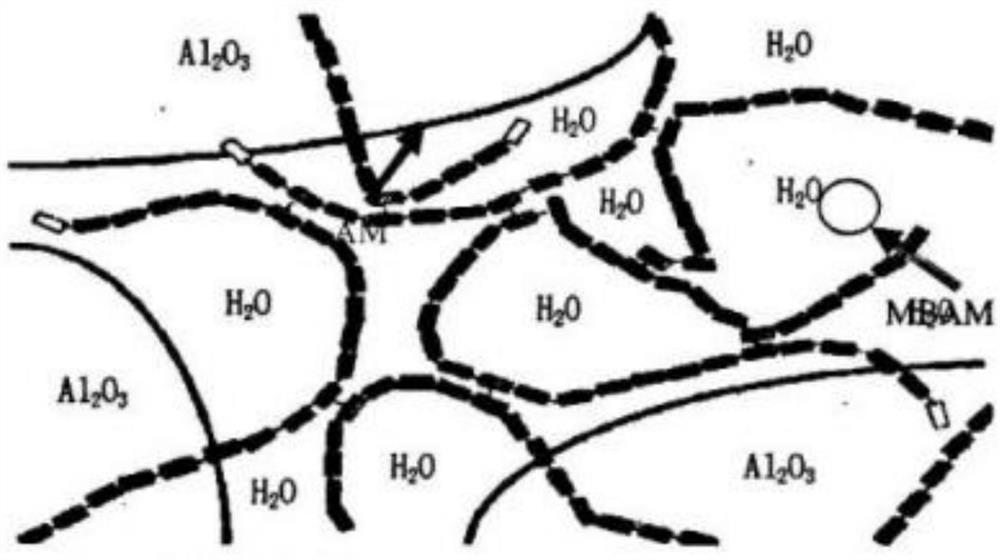

[0024] adjusting the pH value after mixing water, acrylamide, bis-methylene acrylamide and a dispersant to obtain a premix;

[0025] mixing the premix liquid, ceramic powder and molding additives to obtain a mixed slurry;

[0026] Mixing the mixed slurry, the initiator and the catalyst to carry out a polymerization reaction to obtain a polymerization product slurry;

[0027] The polymerization product slurry is sequentially injected into a mold, demolded and dried to obtain a green body; the green body is subjected to debinding and sintering to obtain a sound-absorbing microporous art decorative tile.

[0028] In the invention, the pH value is adjusted after mixing water, acrylamide, bis-methylene acrylamide and a dispersant to obtain a premixed liquid.

[0029] In the present invention, the water is preferably pure water.

[0030] In the ...

Embodiment 1

[0085] Mix 2790g of purified water, 810g of acrylamide, 28g of bismethylene acrylamide, and 40g of ammonium citrate 5027, adjust the pH of the solution to 10.5 with ammonia water, and obtain a premix;

[0086] Add the prepared ceramic powder to the premix solution in 3 times, the first time: 9930g, ball mill for 15 minutes; the second time, 4965g ball mill for 15 minutes; add 4965g ball mill for 8 hours, filter to obtain 23610g mixed slurry;

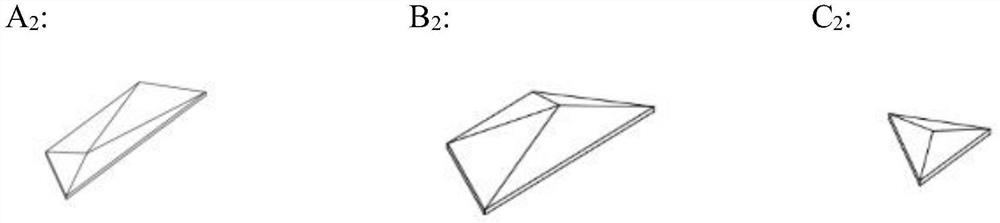

[0087] Pour the mixed slurry into A 1 , B 1 、C 1 In the bucket, add 4g castor oil, 14g silicone defoamer CK-0212, 14g polyethylene glycol (molecular weight 20000), 500g polyethylene glycol (molecular weight 6000), stir at 300r / h for 20min, and wait until no After bubbling, add 9g of ammonium persulfate and 3g of tetramethylethylenediamine each, evacuate, and quickly pour 3 different A 2 , B 2 、C 2 The molded high-hardness plastic PE mold is pressurized to make it solidify naturally;

[0088] Green body A to be solidified 2 , B 2 ...

Embodiment 2

[0097] Mix 2000 g of purified water, 560 g of acrylamide, 20 g of bismethylene acrylamide, and 28 g of ammonium citrate 5027, adjust the pH of the solution to 10.5 with ammonia water, and obtain a premix;

[0098] The addition amount of other raw materials can be added according to the limited ratio; other implementation methods are the same as in Example 1.

[0099] The sound-absorbing microporous artistic decorative tiles prepared in Example 2 were tested, and the data were basically the same as those in Example 2, so details will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com