Vegetable oil-based textbook and periodical ink and preparation process thereof

A vegetable oil-based, preparation technology, which is applied in the field of printing inks, can solve problems such as health hazards, high VOC emissions, environment, atmosphere, and ecological pollution, and achieve energy saving, prolonging preparation time, and increasing bright colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of high viscosity rosin modified phenolic resin

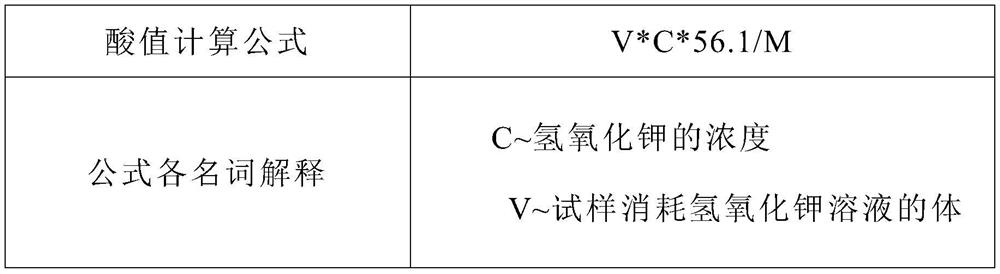

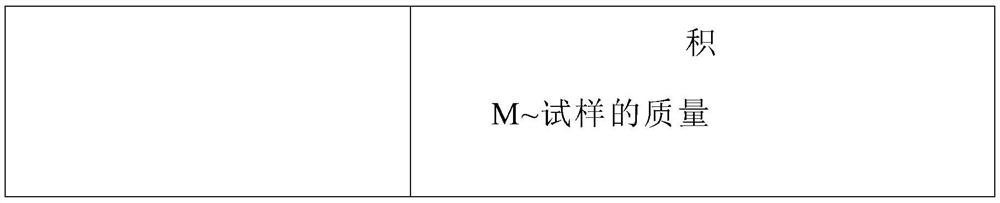

[0040] In the reaction kettle with condensation, reflux device and nitrogen protection at normal pressure, by weight, 54.5 parts of melted rosin liquid were slowly added at 230 °C to 4 parts of condensation products of p-tert-butylphenol and formaldehyde, 40.5 parts of condensates of p-tert-octylphenol and formaldehyde were reacted with it; after about 1 hour, the temperature was raised to 245°C, and 3 parts of pentaerythritol and 0.5 parts of glycerin were added, and after stirring evenly, 0.31 parts of p-toluenesulfonic acid was added dropwise to lower the temperature Rise to 250°C and carry out esterification reaction; take a sample after two hours, when AV=30, add 1.5 parts of p-tetraoctylphenol and formaldehyde condensate to continue the reaction until the acid value of the reactant: AV≤25mgKOH / g At this time, the viscosity of the reactant is 15000MPa·s / 25°C, and the tolerance of n-heptane is ≥11mL / 2...

Embodiment 2

[0051] (1) Preparation of high viscosity rosin modified phenolic resin

[0052] In the reaction kettle with condensation, reflux device and nitrogen protection at normal pressure, by weight, 54 parts of melted rosin liquid were slowly added to 5.4 parts of condensate of nonylphenol and formaldehyde, 33.7 parts of ~Condensate of tert-octylphenol and formaldehyde react with it; after about 1 hour, heat up to 245°C, add 3 parts of glycerol and 0.5 part of glycerin, stir evenly, add 0.31 parts of p-toluenesulfonic acid dropwise, and the temperature rises to 250 Carry out esterification reaction at ℃; take a sample after two hours, when AV=30, add 2.5 parts of p-tertoctylphenol and formaldehyde condensate to continue the reaction, take a sample after 4 hours and measure until the acid value of the reactant: AV≤25mgKOH / g, at this time, the viscosity of the reactant is 15000MPa·s / 25°C, the n-heptane tolerance is ≥11mL / 2g, the temperature is lowered to 130°C, the reaction is stopped,...

Embodiment 3

[0063](1) Preparation of high viscosity rosin modified phenolic resin

[0064] In the reactor with condensation, reflux device and nitrogen protection at normal pressure, by weight, 54 parts of melted rosin liquid were slowly added to 4.5 parts of condensation products of dodecylphenol and formaldehyde, 33.7 parts at 230 ° C, respectively. react with the condensate of p-tert-octylphenol and formaldehyde; after about 1 hour, raise the temperature to 245°C, add 2.7 parts of trimethylolpropane and 0.5 parts of glycerin, stir well and add 0.31 parts of p-toluenesulfonic acid dropwise , the temperature rises to 250°C for esterification reaction; take a sample two hours later, when AV=30, add 0.5 parts of p-tertoctylphenol and formaldehyde condensate to continue the reaction, take a sample after 4 hours and measure until the reaction product is acidic Price: AV≤25mgKOH / g, at this time, the viscosity of the reactant is 15000MPa s / 25°C, the tolerance of n-heptane is ≥11mL / 2g, the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com