Gear oil and preparation method thereof

A synthetic oil and base oil technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as scrapping and gearbox damage, and achieve the effects of reducing costs, smooth shifting, and shortening shift response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 prepares gear oil A:

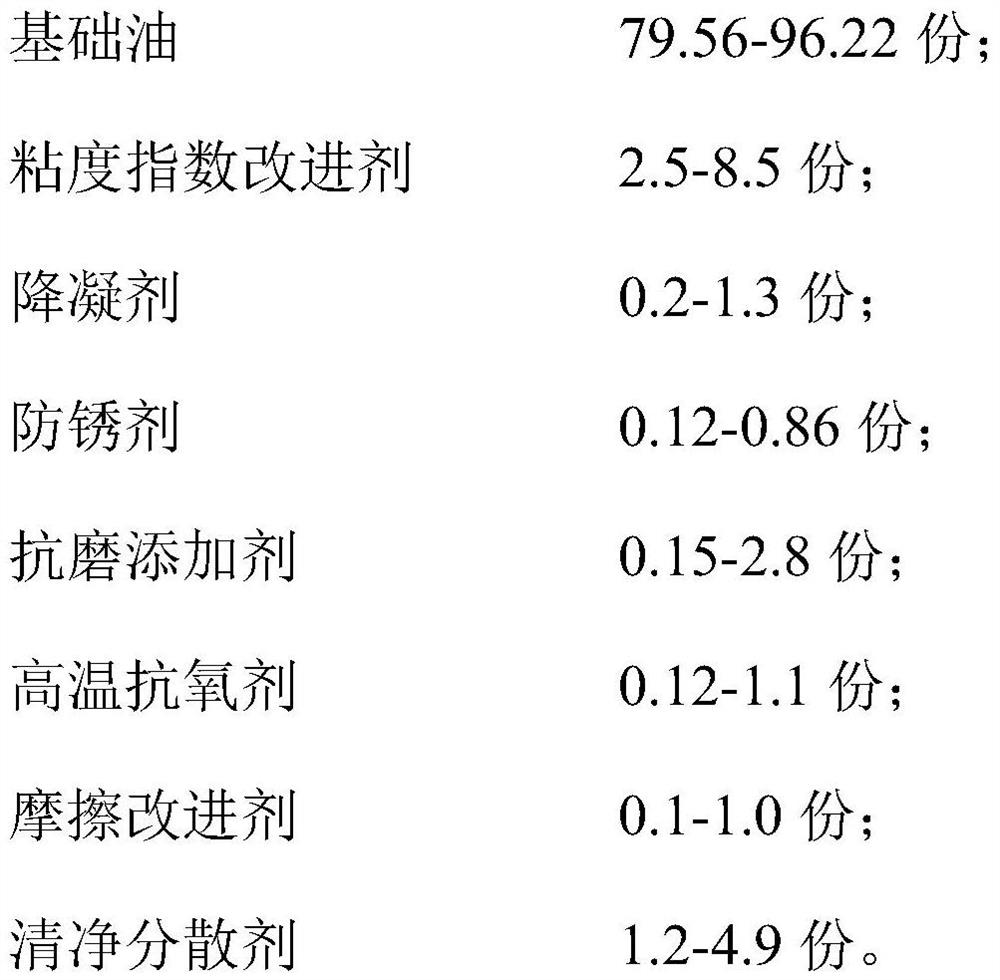

[0034] formula:

[0035]

[0036] Wherein, the base oil component is by weight ratio: natural gas synthetic oil: polyalphaolefin synthetic oil: ester synthetic oil=25: 55: 20, and the 100 ℃ kinematic viscosity of natural gas synthetic oil and polyalphaolefin synthetic oil is 6cst , ester synthetic oil is polyol ester;

[0037]The anti-wear additive components are in the ratio by weight: dithiophosphoric acid acrylate: fatty acid diethanolamide phosphate: C60N-acyl amino acid derivative = 30: 45: 25;

[0038] The detergent and dispersant has a ratio by weight of magnesium borate succinimide:polyisobutenyl succinimide=35:65.

[0039] Preparation:

[0040] (1) Add the base oil into the stainless steel blending kettle with agitator; (2) Stir and heat up to 68°C, then add viscosity index improver and pour point depressant, and continue stirring for 2 hours; (3) Gradually lower the temperature When it reaches 52°C, add antirust agent...

Embodiment 2

[0041] Embodiment 2 prepares gear oil B:

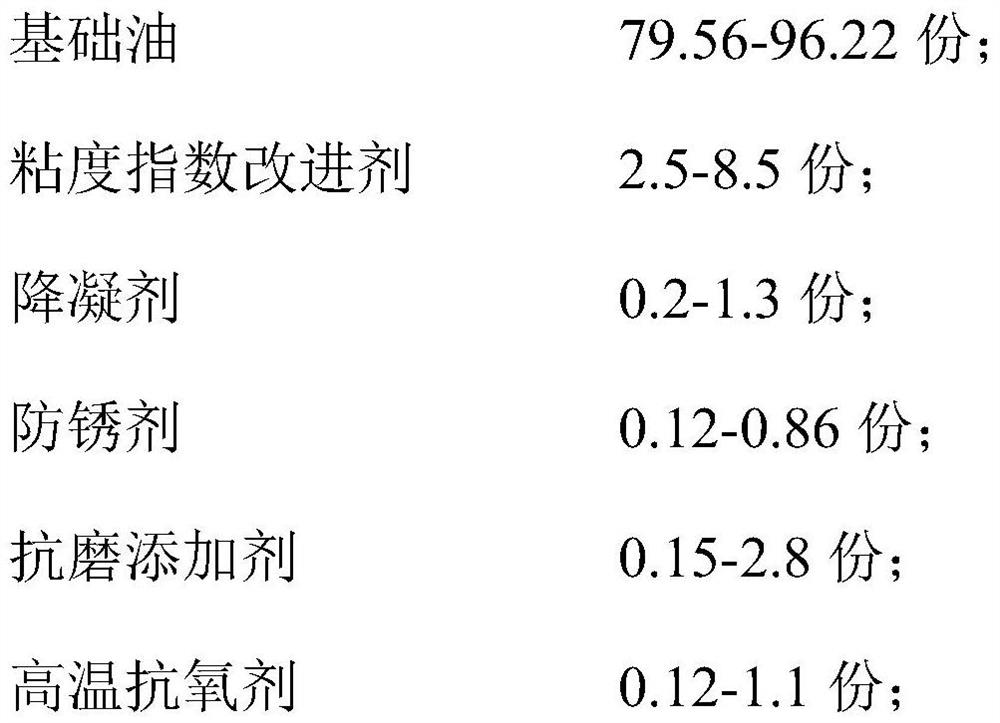

[0042] formula:

[0043]

[0044] Wherein, the base oil component is by weight ratio: natural gas synthetic oil: polyalphaolefin synthetic oil: ester class synthetic oil=80: 15: 5, the 100 ℃ kinematic viscosity of natural gas synthetic oil, polyalphaolefin synthetic oil is 4cst , ester synthetic oil is diester;

[0045] The anti-wear additive components are in the ratio by weight: dithiophosphoric acid acrylate: fatty acid diethanolamide phosphate: C60N-acyl amino acid derivative = 60: 30: 10;

[0046] Detergent and dispersant ratio by weight of magnesium borate succinimide: polyisobutenyl succinimide

[0047] =50:50.

[0048] Preparation:

[0049] (1) Add the base oil into the stainless steel blending kettle with agitator; (2) Stir and heat up to 76°C, then add viscosity index improver and pour point depressant, and continue stirring for 2 hours; (3) Gradually lower the temperature When the temperature reaches 60°C, add antir...

Embodiment 3

[0050] Embodiment 3 prepares gear oil C:

[0051] formula:

[0052]

[0053]

[0054] Wherein, the base oil component ratio by weight is: natural gas synthetic oil: polyalphaolefin synthetic oil: ester synthetic oil=45:45:10, the 100 ℃ kinematic viscosity of natural gas synthetic oil is 4cst, the polyalphaolefin synthetic oil The kinematic viscosity at 100°C is 6cst, and the ester synthetic oil is a mixture of monoester, diester, polyol ester and complex ester in the same proportion;

[0055] The pour point depressant is a mixture of polyalphaolefin and polymethacrylate in the same proportion;

[0056] The antirust agent is a mixture of borated succinimide, alkenyl succinic acid half ester, and borated fatty acid hydroxyethyl ester in the same proportion;

[0057] The anti-wear additive components are in the ratio by weight: dithiophosphoric acid acrylate: fatty acid diethanolamide phosphate: C60N-acyl amino acid derivative = 49: 35: 16;

[0058] The high temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com