Cutting method of GaAs-based LED chip

A technology of LED chip and cutting method, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as unrealizable structure and photoresist deformation, and achieve the effects of avoiding excessive temperature, ensuring integrity, and convenient removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for cutting a GaAs-based LED chip, the specific steps comprising:

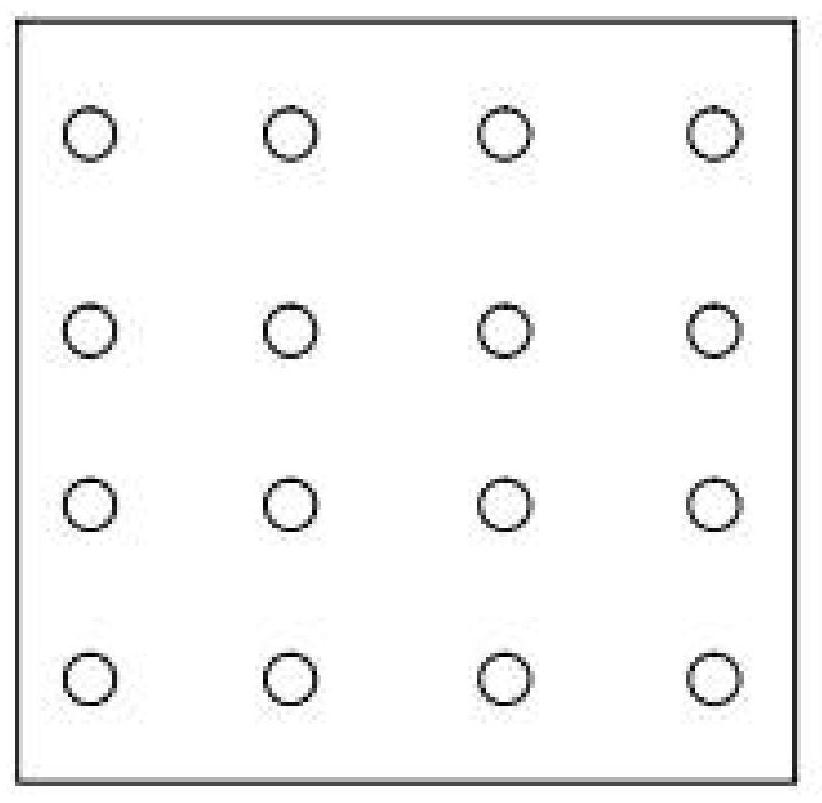

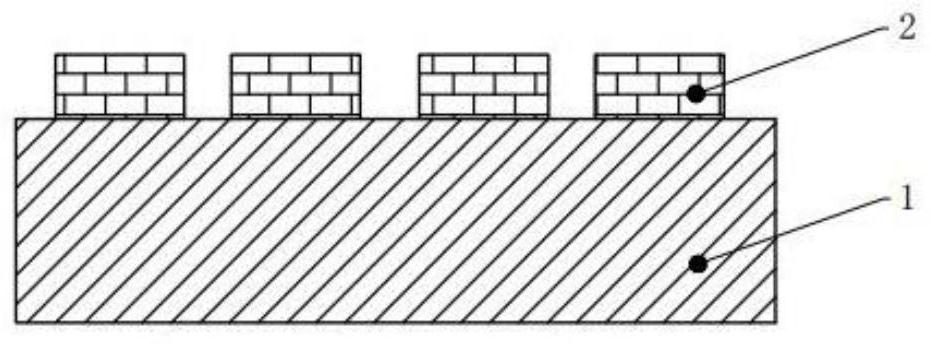

[0053] (1) COW, the pre-process semi-finished product of GaAs-based LED chips, the P side where the P electrode 2 on the epitaxial layer 1 of the COW is also called the front side of the COW, and the structure is as follows figure 1 As shown, the COW is ground to 120 μm, and the schematic diagram of the interface structure after COW grinding is shown in image 3 shown.

[0054] (2) On the N side of COW, also known as the back side of COW, vapor-deposit ohmic contact metal film layer 3, which is a composite ohmic contact metal film layer of Ge / Au, and make ohmic contact metal film layer on the N side of COW. The schematic diagram of the interface structure after layer 3 is shown in Figure 4 As shown, the thickness of the ohmic contact metal film layer 3 is 0.5 μm.

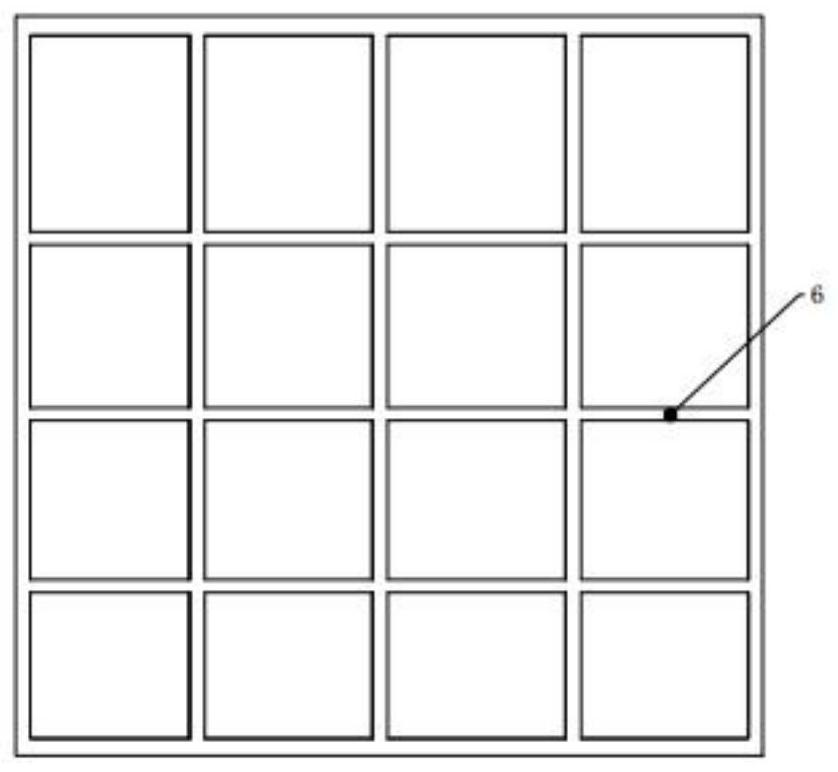

[0055] (3) Utilize the double-sided positioning photolithography process to make a chip dicing line corresponding to the P side...

Embodiment 2

[0062] According to the cutting method of a GaAs-based LED chip provided in Embodiment 1, the difference is that:

[0063] In step (1), the pre-process semi-finished product COW of the GaAs-based LED chip is ground to 160 μm.

[0064] In step (2), the ohmic contact metal film layer 3 is vapor-deposited on the N surface of the semi-finished COW. The material of the ohmic contact metal film layer 3 is a composite metal film layer of Ni / Ge / Au, and the thickness of the ohmic contact metal film layer 3 is 5 μm. .

[0065] In step (3), using a double-sided positioning photolithography process, a chip dicing line corresponding to the P side is made on the N side, and the ohmic contact metal film layer 3 on the N side is corroded by an corrosive solution to form a dicing line 6, and the dicing line 6 The width is 30 μm.

[0066] In step (5), the etching conditions are as follows: feed the etching gas as Cl 2 and Ar, where Cl 2 The gas flow rate of Ar is 100 sccm, the gas flow rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com