Preparation method of monocrystal lithium manganate material

A single crystal lithium manganate and raw material technology, which is applied in the field of preparation of single crystal lithium manganate materials, can solve the problems of low compaction density, small size, and many crystal defects, and achieves high premiere and cycle performance, high pressure High solid density and good magnification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

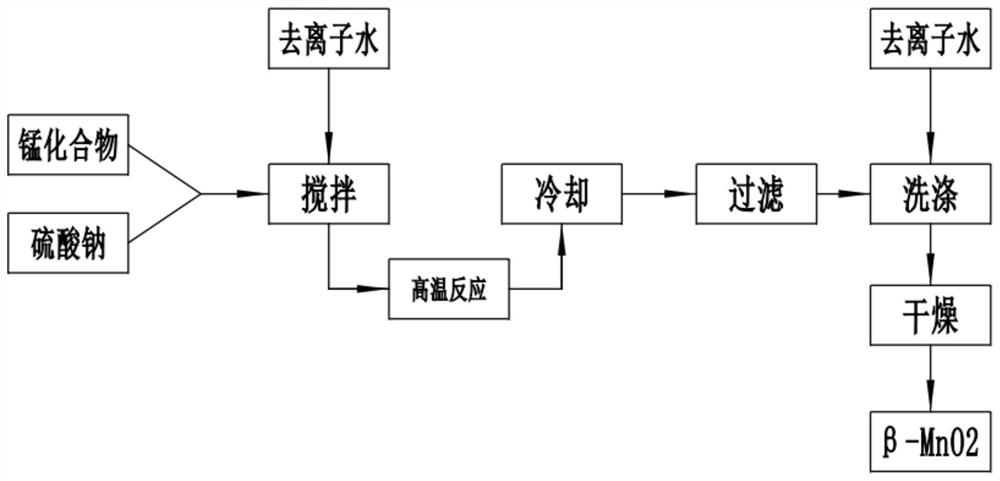

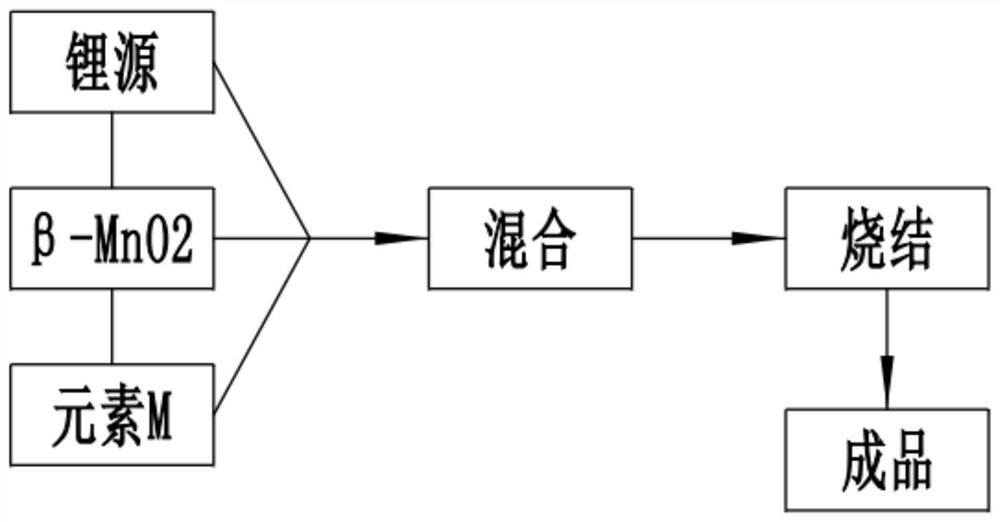

[0046] The present invention provides a preparation method of single crystal lithium manganate material by improving, such as Figure 1-Figure 2 As shown, including the following steps:

[0047] Ⅰ: Weigh the raw material manganese compound and sodium sulfate and sodium sulfate according to the required ratio. It has stable chemical properties, is insoluble in strong acid, absorbs moisture, and becomes hydrated sodium sulfate when exposed to the air; it turns into hexagonal crystal at 241℃, high The pure, fine-grained anhydrous is called sodium sulfate, which is easily soluble in water and has a cooling sensation; it has a cool and salty taste, and is easily hydrated in moist air, transforming into powdery hydrated sodium sulfate and covering the surface;

[0048] Ⅱ: Add the raw materials that have been proportioned in step Ⅰ into the stirred reactor, and add a certain amount of deionized water for stirring;

[0049] Ⅲ: Add the uniformly stirred raw materials in step Ⅱ into the high-...

Embodiment 1

[0079] A preparation method of single crystal lithium manganate material includes the following steps:

[0080] Ⅰ: Weigh the raw material manganese compound and sodium sulfate and sodium sulfate according to the required ratio. It has stable chemical properties, is insoluble in strong acid, absorbs moisture, and becomes hydrated sodium sulfate when exposed to the air; it turns into hexagonal crystal at 241℃, high The pure, fine-grained anhydrous is called sodium sulfate, which is easily soluble in water and has a cooling sensation; it has a cool and salty taste, and is easily hydrated in moist air, transforming into powdery hydrated sodium sulfate and covering the surface;

[0081] Ⅱ: Add the raw materials that have been proportioned in step Ⅰ into the stirred reactor, and add a certain amount of deionized water for stirring;

[0082] Ⅲ: Add the uniformly stirred raw materials in step Ⅱ into the high-temperature reaction kettle for high-temperature reaction;

[0083] Ⅳ: The raw materi...

Embodiment 2

[0114] A preparation method of single crystal lithium manganate material includes the following steps:

[0115] Ⅰ: Weigh the raw material manganese compound and sodium sulfate and sodium sulfate according to the required ratio. It has stable chemical properties, is insoluble in strong acid, absorbs moisture, and becomes hydrated sodium sulfate when exposed to the air; it turns into hexagonal crystal at 241℃, high The pure, fine-grained anhydrous is called sodium sulfate, which is easily soluble in water and has a cooling sensation; it has a cool and salty taste, and is easily hydrated in moist air, transforming into powdery hydrated sodium sulfate and covering the surface;

[0116] Ⅱ: Add the raw materials that have been proportioned in step Ⅰ into the stirred reactor, and add a certain amount of deionized water for stirring;

[0117] Ⅲ: Add the uniformly stirred raw materials in step Ⅱ into the high-temperature reaction kettle for high-temperature reaction;

[0118] Ⅳ: The raw materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com