Friction nano-generator for capturing wind energy and sound energy

A nano-generator and nano-power generation technology, which is applied in friction generators, wind power generation, and wind power generators in the same direction as the wind, can solve the problems of lack of simultaneous capture of wind energy and sound energy, weak output effects, etc., and achieve open-circuit voltage enhancement , the effect of improving the output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

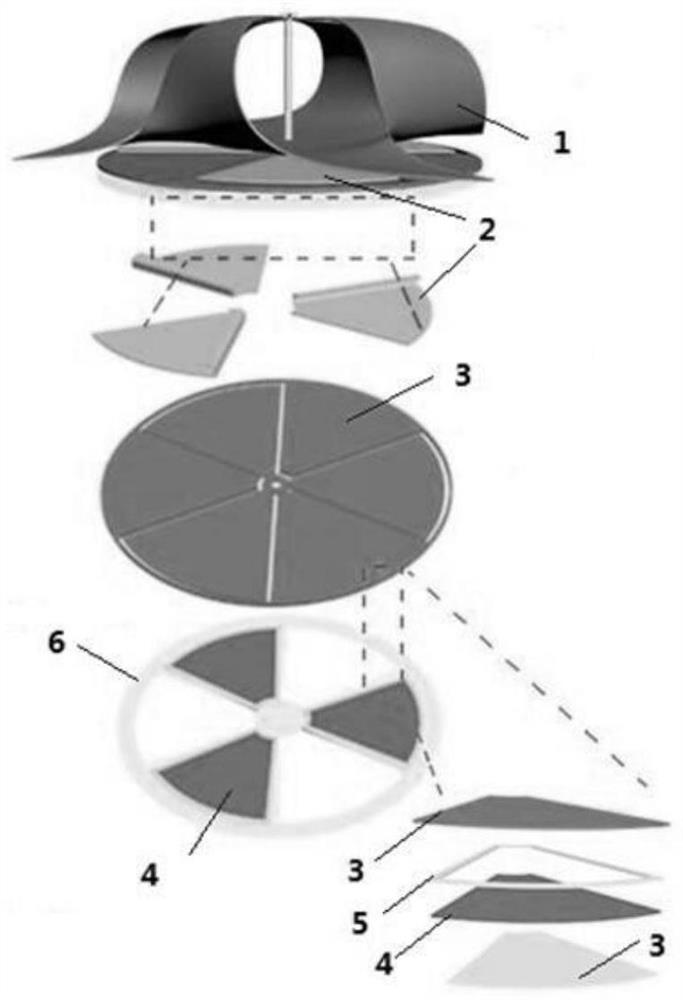

[0033] Example one, such as figure 1 As shown, a friction nanogenerator for capturing wind and sound energy includes a wind-driven friction nanometer power generation device and a sound-driven friction nanometer power generation device.

[0034] The wind-driven friction nano power generation device includes a 28 cm diameter windmill 1, three pieces of polytetrafluoroethylene friction layer (PTFE) 2 attached to the windmill 1, and two complementary conductive fabrics 3 made of interdigital electrodes. In order to facilitate the fixation of the interdigital electrodes, a disc 6 made of acrylic plate was made. First, the acrylic plate was cut into a radial disc (outer diameter 19cm) with a laser engraving machine as the wind-driven friction nano generator The bracket, the disc 6 is composed of six fan-shaped parts, each of which has a radius of 7 cm and a central angle of 60°.

[0035] Two conductive fabrics 3 are pasted on the disc 6 by double-sided tape and separated by a small gap ...

Embodiment 2

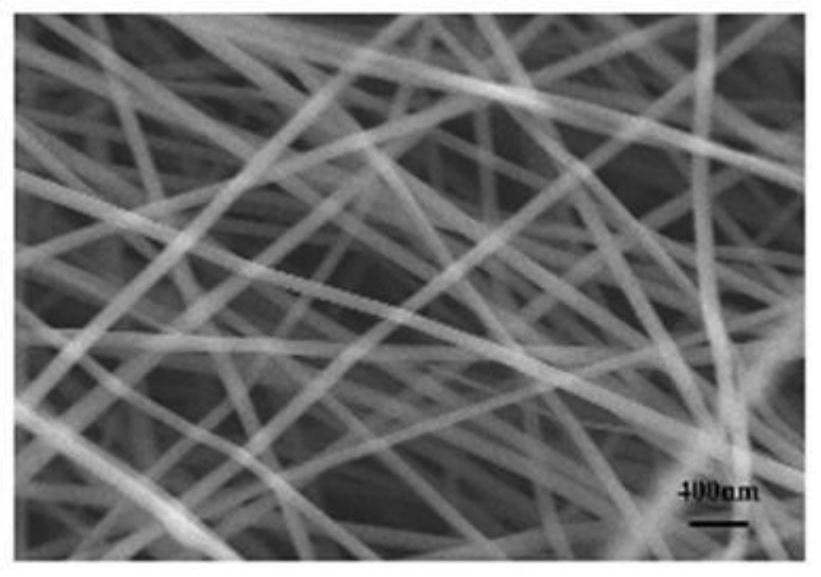

[0039] Example 2: The polyvinylidene fluoride-trifluoroethylene nanofiber membrane and the conductive fabric in Example 1 are analyzed, and the results are as follows figure 2 with 3 Shown.

[0040] figure 2 Shows the SEM image of the polyvinylidene fluoride-trifluoroethylene nanofiber membrane prepared by a domestic electrospinning device (equipped with a rotating drum collector). The average diameter of the polyvinylidene fluoride-trifluoroethylene nanofiber membrane is Composed of 100nm polyvinylidene fluoride-trifluoroethylene (P(VDF-TrFE)) nanofibers, the nanofibers look straight and uniform.

[0041] image 3 The SEM image of the conductive fabric is shown, which is a square array of micro-holes with a side length of 65 μm. The inherent rectangular micro-hole structure in the conductive fabric is beneficial to the transmission of sound to the friction layer of the polyvinylidene fluoride-trifluoroethylene nanofiber membrane.

Embodiment 3

[0042] The third embodiment analyzes the mechanism of wind energy collected by the wind-driven friction nano power generation device and sound wave energy collected by the sound driven friction nano power device in the first embodiment.

[0043] The wind-driven friction nano power generation device is a kind of friction nano generator based on the independent layer mode. The interdigital electrode made of conductive fabric on the stator (disk 6) and the rotor (windmill 1) are on the polytetrafluoroethylene friction layer (PTFE). Under the relative rotational movement of ), AC power is supplied to the external load. Such as Figure 4 As shown, the first contact electrode of the PTFE membrane is marked as electrode F, and the electrode next to electrode F is named electrode N. In the initial state ( Figure 4 -i) Once the PTFE membrane is in physical contact with the electrode F, the surface of the PTFE membrane is negatively charged due to the different polarities of different fri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com