Oily system containing 3,4-dihydroxyphenylethanol, and preparation method and applications thereof

A dihydroxyphenethyl alcohol and system technology, applied in the field of materials, can solve the problems of limited in-depth development, instability, easy occurrence of oxidative discoloration, etc., to avoid oxidative discoloration, good practical value, good light stability and thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

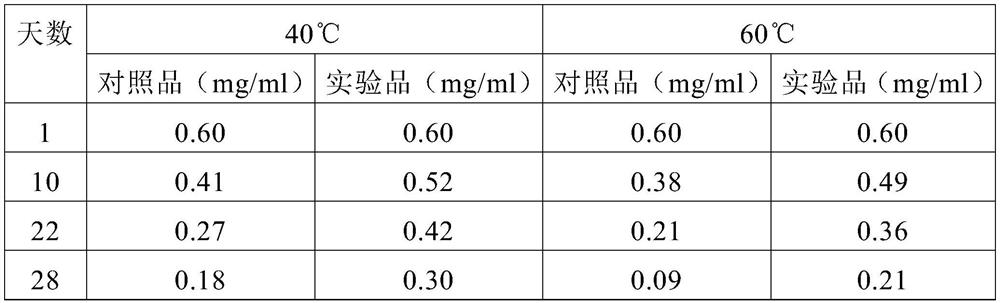

[0022] This embodiment provides an oily system containing 3,4-dihydroxyphenethyl alcohol. The oily system includes: 3,4-dihydroxyphenethyl alcohol, an oily solvent and a protective agent. Wherein, the oily solvent includes: sesame oil and walnut oil; the protective agent is p-hydroxyacetophenone. In terms of parts by mass, the composition of the oily system is 1.2 parts of 3,4-dihydroxyphenethyl alcohol, 996 parts of sesame oil, 996 parts of walnut oil, and 1.5 parts of p-hydroxyacetophenone. Wherein, the concentration of the oily system containing 3,4-dihydroxyphenethyl alcohol in this embodiment is 0.6 mg / ml.

[0023] The preparation method of the oily system provided in this embodiment includes the following steps:

[0024] Step 1: Weigh 996 parts of sesame oil and 996 parts of walnut oil, stir evenly, and heat to 20°C to prepare a hot oily solution; wherein, the heating method in step 1 is preferably water bath heating. Step 2: Weigh 1.2 parts of 3,4-dihydroxyphenethyl alcoho...

Embodiment 2

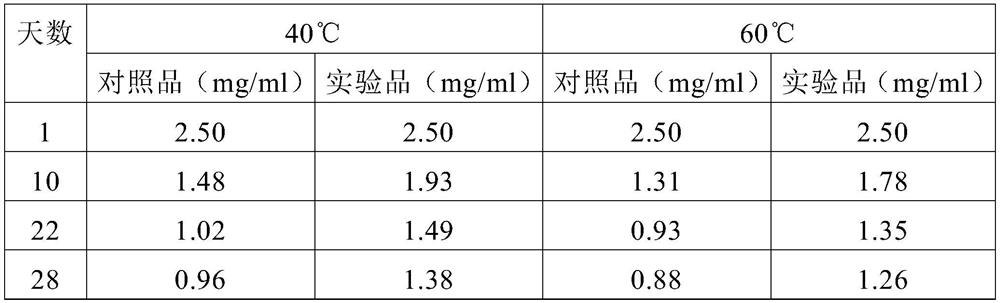

[0033] The difference from the above embodiment is that the oily solvent in this embodiment includes cottonseed oil and grapeseed oil; the protective agent is phytic acid. In terms of parts by mass, the composition of the oily system is: 4.9 parts of 3,4-dihydroxyphenylethanol, 1120 parts of cottonseed oil, 830 parts of grape seed oil, and 5.2 parts of phytic acid. Wherein, the concentration of the oily system containing 3,4-dihydroxyphenethyl alcohol in this embodiment is 2.50 mg / ml.

[0034] The preparation process of the oily system in this embodiment includes the steps:

[0035] Step 1. Weigh 1120 parts of cottonseed oil and 830 parts of grapeseed oil, stir evenly, and heat to 24°C to prepare a hot oily solution. Step 2: Weigh 4.9 parts of 3,4-dihydroxyphenethyl alcohol and 5.2 parts of phytic acid respectively. Step 3. Slowly add the weighed 3,4-dihydroxyphenethyl alcohol dropwise to the hot oily solution in step 1, stir and mix evenly at constant temperature; add the weighe...

Embodiment 3

[0045] The difference from the above embodiment is that the oily solvent in this embodiment includes rapeseed oil and soybean oil; the protective agent includes vitamin E succinate and N-acetylcysteine. In terms of parts by mass, the composition of the oily system is: 27.3 parts of 3,4-dihydroxyphenylethanol, 930 parts of rapeseed oil, 420 parts of soybean oil, 5.5 parts of vitamin E succinate, and N-acetylcysteine 4.8 copies. Wherein, the concentration of the oily system containing 3,4-dihydroxyphenethyl alcohol in this embodiment is 19.67 mg / ml.

[0046] The preparation process of the oily system in this example is:

[0047] Step 1: Weigh 930 parts of rapeseed oil and 420 parts of soybean oil, stir evenly and heat to 28°C to prepare a hot oily solution. Step 2: Weigh 27.3 parts of 3,4-dihydroxyphenethyl alcohol, 5.5 parts of vitamin E succinate and 4.8 parts of N-acetylcysteine. Step 3. Add the weighed 3,4-dihydroxy phenethyl alcohol slowly to the hot oily solution in step 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com