Preparation method of silicon carbide nanowires in situ toughened ceramic precursor type high temperature adhesive

A technology of in-situ growth of silicon carbide nanowires, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of high temperature resistant glue porosity, reduced compactness, and attenuation of bonding effect, and achieve bonding strength Improvement, brittleness improvement, and the effect of repairing the inner structure of the rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The silicon carbide nanowire in-situ growth toughened ceramic precursor type high-temperature adhesive provided in this example includes the following steps in order:

[0028] (1) Mix vinyl polycarbosilane, polymethyl siloxane, phenolic resin, ferrocene and isopropanol according to the mass ratio of 3.5:1.5:1:0.6:2.5, and then stir at 65°C 5h to prepare gum base liquid;

[0029] (2) Fully mix aluminum powder, nickel powder, silicon powder, boron carbide powder and borate glass powder according to the mass ratio of 1.5:1:0.35:0.2:0.1 to prepare a filler mixture;

[0030] (1) Mix the gum base liquid prepared in step (1) and the filler mixture prepared in step (2) in a ball mill tank at a liquid-to-solid mass ratio of 5:4, and ball mill for 2 hours at a speed of 200r / min to obtain a viscosity of about 2500cps Gray-black silicon carbide nanowires in situ growth toughened ceramic precursor type high temperature glue.

Embodiment 2

[0032] (1) Mix vinyl polycarbosilane, polymethyl siloxane, phenolic resin, ferrocene and isopropanol according to the mass ratio of 4:2:1.25:0.9:2, and then carry out at 65°C Stir for 6 hours to prepare a gum base solution.

[0033] (2) Fully mix aluminum powder, nickel powder, silicon powder, boron carbide powder and trace borate glass powder according to the mass ratio of 2:1.5:0.5:0.15:0.2 to prepare a filler mixture;

[0034] (3) Mix the gum base liquid prepared in step (1) and the filler mixture prepared in step (2) in a ball mill tank according to the liquid-solid mass ratio of 6:5, and ball mill for 3 hours at a speed of 200r / min to obtain a viscosity of about 2500cps Gray-black silicon carbide nanowires in situ growth toughened ceramic precursor type high temperature glue.

Embodiment 3

[0036] (1) Mix vinyl polycarbosilane, polymethyl siloxane, phenolic resin, ferrocene and isopropanol according to the mass ratio of 4.5:1.5:0.75:0.7:1.5, and then carry out at 65°C Stir for 6 hours to prepare a gum base solution.

[0037] (2) Fully mix aluminum powder, nickel powder, silicon powder, boron carbide and a small amount of borate glass powder according to the mass ratio of 2.5:1:0.6:0.3:0.1 to prepare a filler mixture;

[0038] (3) Mix the gum base liquid prepared in step (1) and the filler mixture prepared in step (2) in a ball mill tank according to the liquid-solid mass ratio of 7:5, and ball mill for 3 hours at a speed of 150r / min to obtain a viscosity of about 2500cps Gray-black silicon carbide nanowires in situ growth toughened ceramic precursor type high temperature glue.

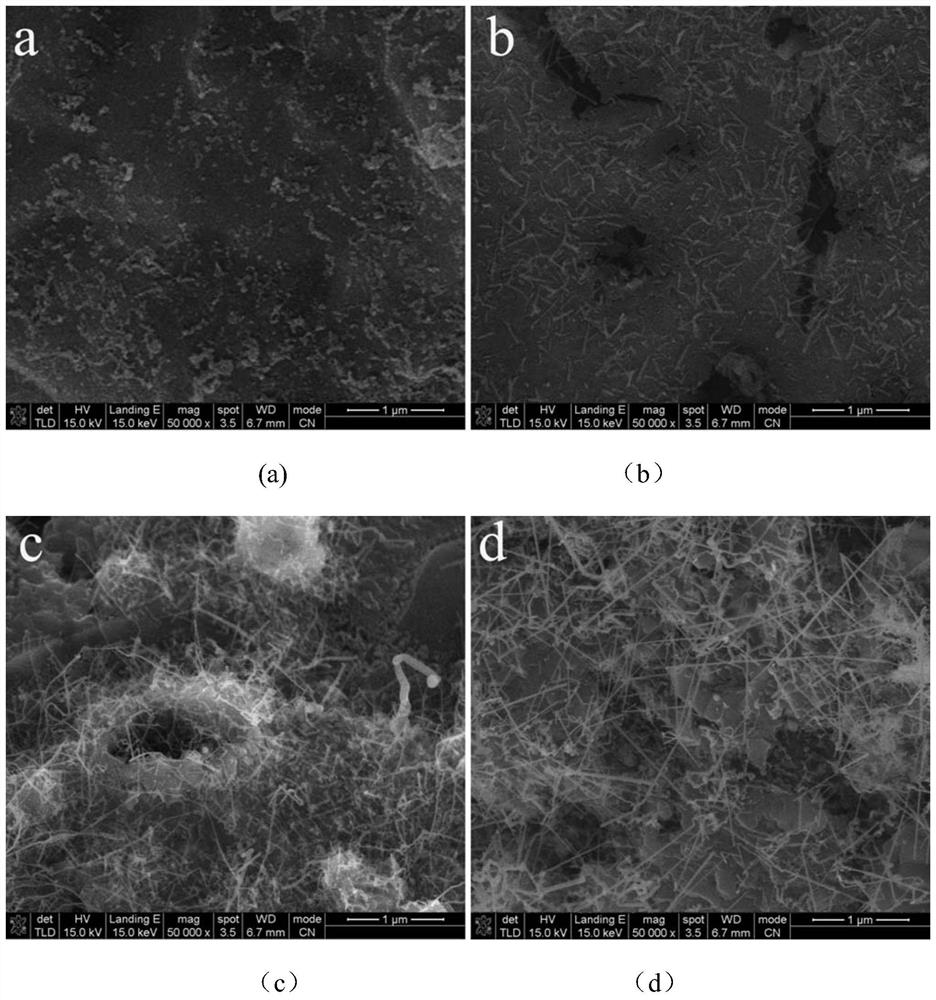

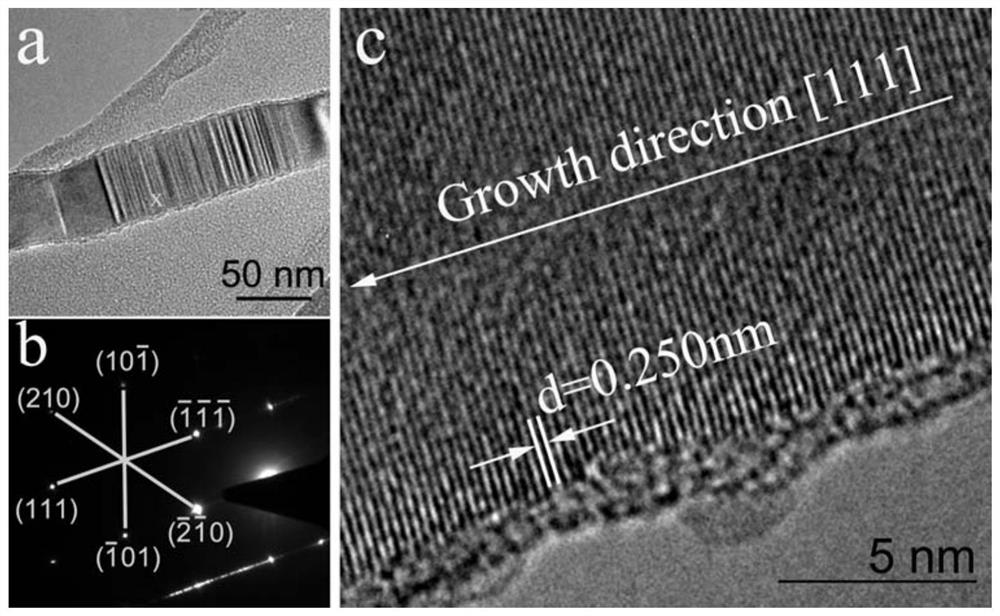

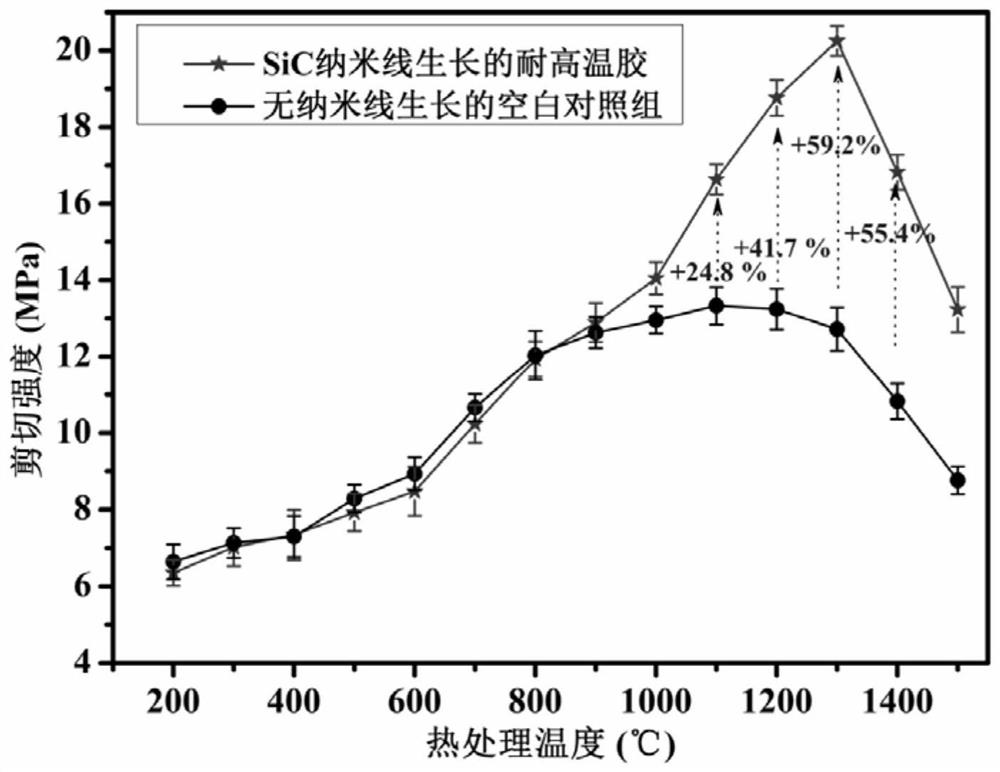

[0039] In the silicon carbide nanowire in-situ growth toughened ceramic precursor type high-temperature glue prepared by the method of the present invention, the main bonding phase is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com