Method for enriching EPA and DHA in deep sea fish oil

A deep-sea fish oil and enrichment technology, which is applied in the direction of oil/fat refining, fat production, fermentation, etc., can solve the problems of difficult enrichment, out-of-sync enrichment, and failure to reach the maximum concentration of DHA, and achieve enrichment improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

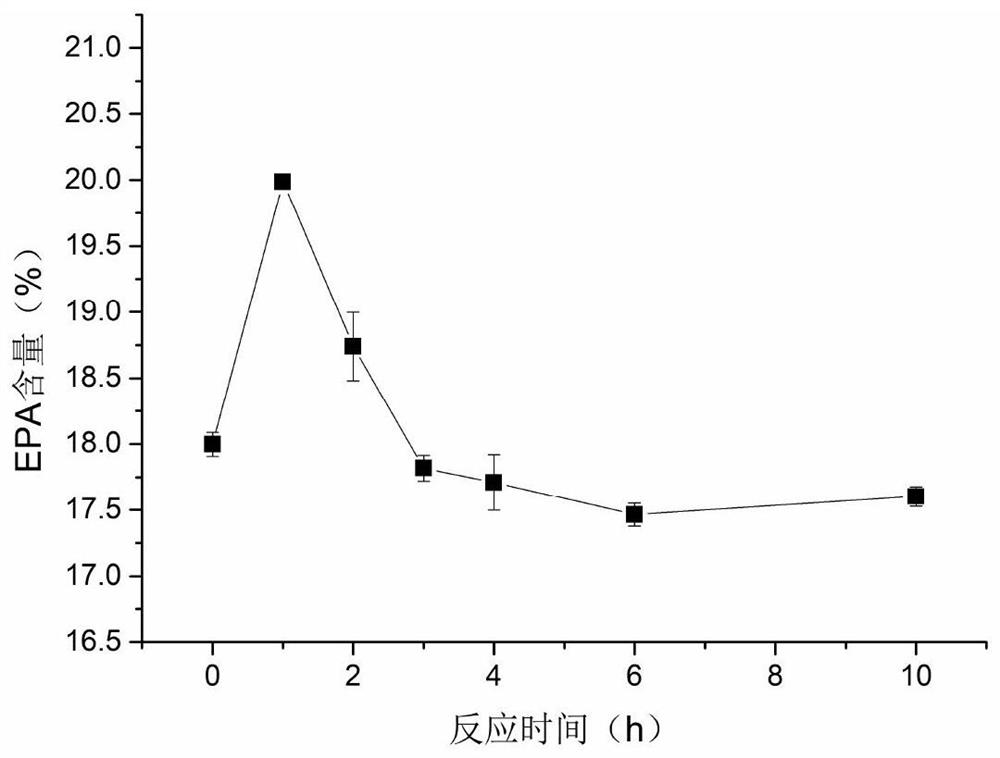

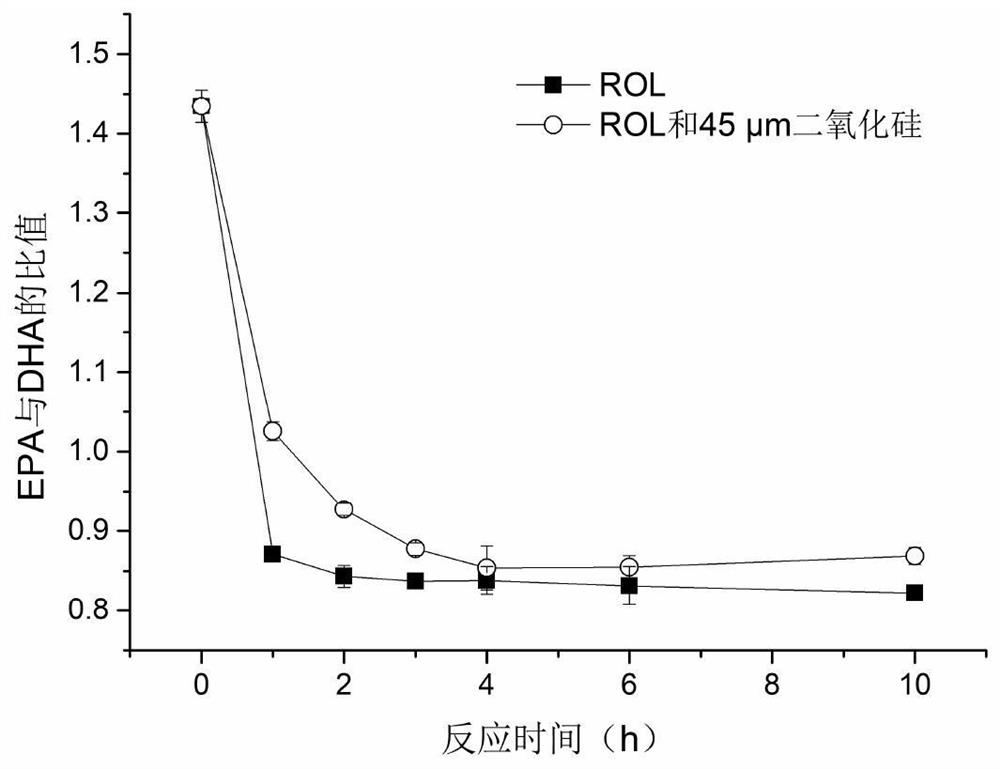

[0020] Embodiment one: the method for EPA and DHA in a kind of enrichment deep-sea fish oil provided by the present invention, the Rhizopus oryzae lipase of 3 weight parts is dissolved in the Tris-HCl damping fluid (0.2mol / L, pH= 7.0), add 5 parts by weight of silicon dioxide particles with a particle size of 45 μm, and prepare a dispersion containing lipase and silicon dioxide after magnetic stirring for 5 minutes. Add 100 parts by weight of deep-sea fish oil to the dispersion, fill the reaction vessel with nitrogen and seal it, the reaction temperature is 40°C, and magnetic stirring is continued during the reaction process, the reaction time is 1-10h, after the reaction is completed, add 400 parts by weight of hydroxide Potassium solution (2mol / L) and 300 parts by weight of n-hexane, fully shaken, centrifuged at 5000g for 30min, transferred the upper layer solution to a new container, blown with nitrogen to remove n-hexane, and the remaining lipid is the product enriched in E...

Embodiment 2

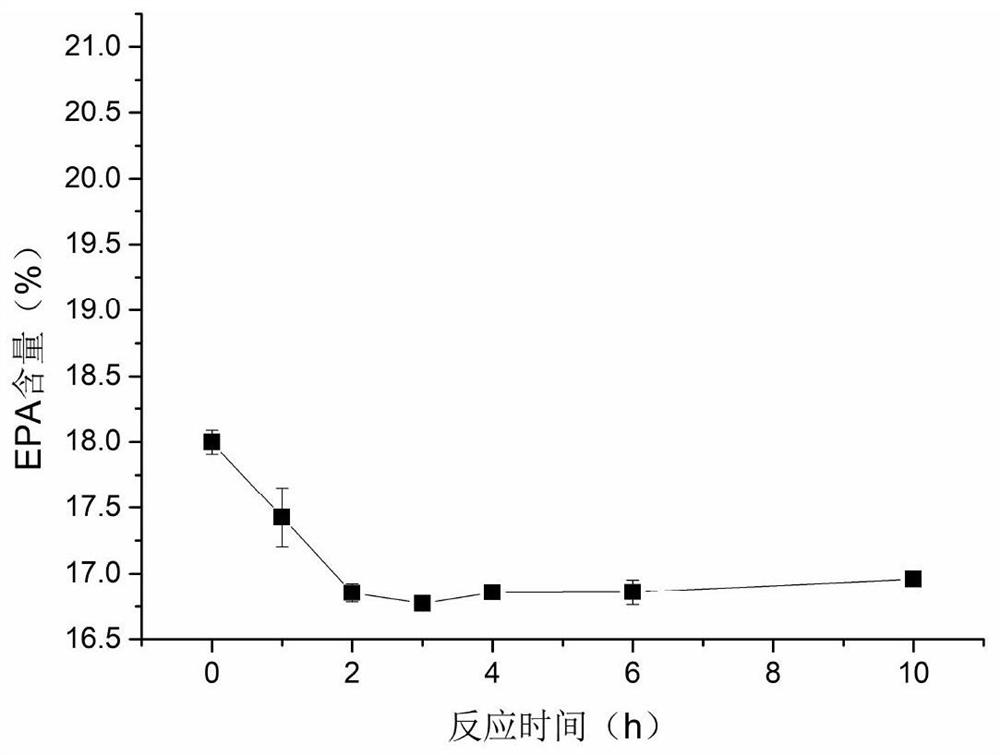

[0022] Embodiment two: the method for EPA and DHA in a kind of enrichment deep sea fish oil provided by the present invention, the Rhizopus oryzae lipase of 3 weight parts is dissolved in the Tris-HCl damping fluid (0.2mol / L, pH= 7.0), add 5 parts by weight of silicon dioxide particles, the particle size of which is 10-20nm, and stir magnetically for 5 minutes to prepare a dispersion containing lipase and silicon dioxide. Add 100 parts by weight of deep-sea fish oil to the dispersion, fill the reaction vessel with nitrogen and seal it, the reaction temperature is 40°C, and magnetic stirring is continued during the reaction process, the reaction time is 1-10h, after the reaction is completed, add 400 parts by weight of hydroxide Potassium solution (2mol / L) and 300 parts by weight of n-hexane, fully shaken, centrifuged at 5000g for 30min, transferred the upper layer solution to a new container, blown with nitrogen to remove n-hexane, and the remaining lipid is the product enriche...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com