Method for increasing starch yield of duckweed mutants through induced mutation by heavy ion radiation

A technology of heavy ion radiation and mutant plants, which is applied in horticultural methods, botanical equipment and methods, plant genetic improvement, etc., can solve the problems of needing to salvage regularly, high cost of large-scale cultivation of duckweed, and restricting the development of duckweed, etc. The effect of high genetic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

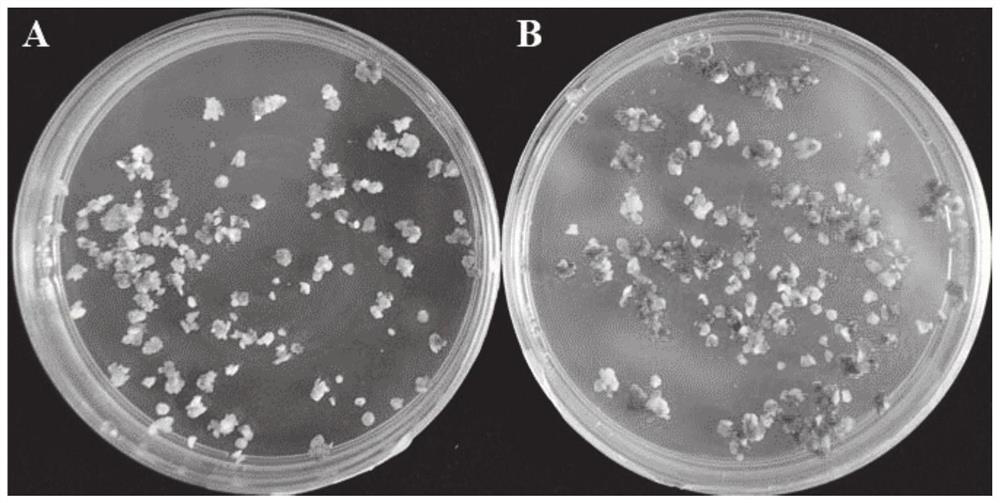

[0042] In the present embodiment, a method for improving the starch production of duckweed mutant strain induced by heavy ion radiation is provided, the method is as follows: the duckweed fronds (Lemna aequinoctialis 6002) in the exponential growth phase are tiled on the MS induction medium Above, cultured in the dark for 7 weeks, transferred to a new MS induction medium, continued to culture in the dark for 5 weeks, and obtained light yellow spherical callus as the starting material for radiation mutagenesis.

[0043] Put the duckweed callus under the vertical irradiation terminal device of the heavy ion accelerator to carry out carbon heavy ion radiation mutagenesis, and the mutagenic energy heavy ion beam current is 12 C 6+ , the energy is 80MeV / u. Dose ranges were set at 10 Gy, 25 Gy, 50 Gy, and 75 Gy.

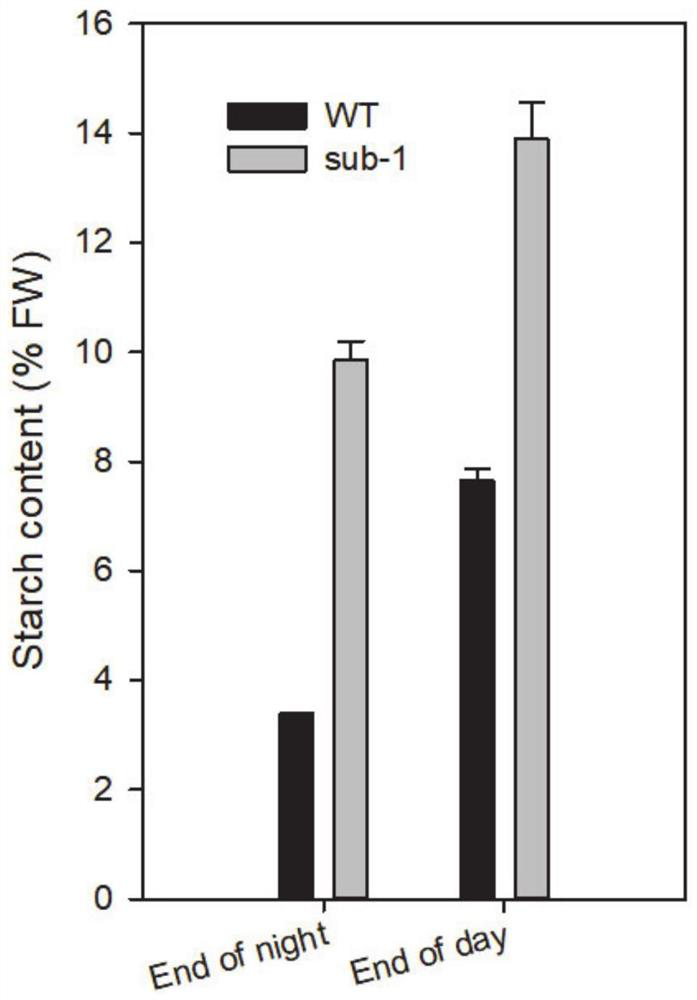

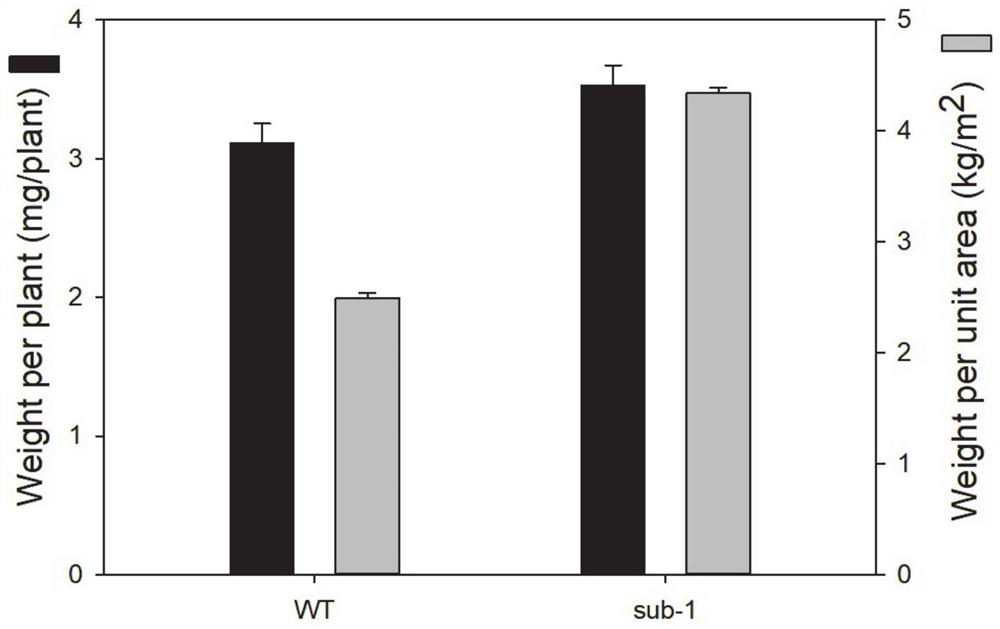

[0044] The callus after the radiation mutagenesis is differentiated and cultured into regenerated plants, and the regenerated plants are obtained and continuously cultur...

Embodiment 2

[0074] In this embodiment, a method for mutagenizing duckweed mutants with high starch yield based on heavy ion radiation is provided, the method is as follows: the duckweed fronds in the exponential growth phase are spread on the MS induction medium, and cultured in the dark for 6 week, transferred to a new MS induction medium, and continued to culture in the dark for 6 weeks to obtain light yellow spherical callus as the starting material for radiation mutagenesis.

[0075] Put the duckweed callus under the vertical irradiation terminal device of the heavy ion accelerator to carry out carbon heavy ion radiation mutagenesis, and the mutagenic energy heavy ion beam current is 12 C 6+ , the energy is 80MeV / u. Dose ranges were set at 10 Gy, 25 Gy, 50 Gy, and 75 Gy.

[0076] The callus after the radiation mutagenesis is differentiated and cultured into regenerated plants, and the regenerated plants are obtained and continuously cultured for several generations and the high-star...

Embodiment 3

[0083] In this embodiment, a method for mutagenizing duckweed mutants with high starch yield based on heavy ion radiation is provided, the method is as follows: the duckweed fronds in the exponential growth phase are spread on the MS induction medium, and cultured in the dark for 7 week, transferred to a new MS induction medium, and continued to culture in the dark for 6 weeks to obtain light yellow spherical callus as the starting material for radiation mutagenesis.

[0084] Put the duckweed callus under the vertical irradiation terminal device of the heavy ion accelerator to carry out carbon heavy ion radiation mutagenesis, and the mutagenic energy heavy ion beam current is 12 C 6+ , the energy is 80MeV / u. Dose ranges were set at 10 Gy, 25 Gy, 50 Gy, and 75 Gy.

[0085] The callus after the radiation mutagenesis is differentiated and cultured into regenerated plants, and the regenerated plants are obtained and continuously cultured for several generations and the high-star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com