Pretreatment method for relieving agaricus bisporus browning and texture collapse and prefabricated dish

A Agaricus bisporus pretreatment technology, applied in the functions of food ingredients, food science, application, etc., can solve the problems of destroying the cell structure of Agaricus bisporus, bad color of Agaricus bisporus, easy to breed microorganisms, etc., to improve the flavor and Nutrition, browning and dehydration softening, strong workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] A pretreatment method of Agaricus bisporus, the steps are as follows:

[0078] Step (1), wash the Agaricus bisporus, cut into 0.5cm thin slices;

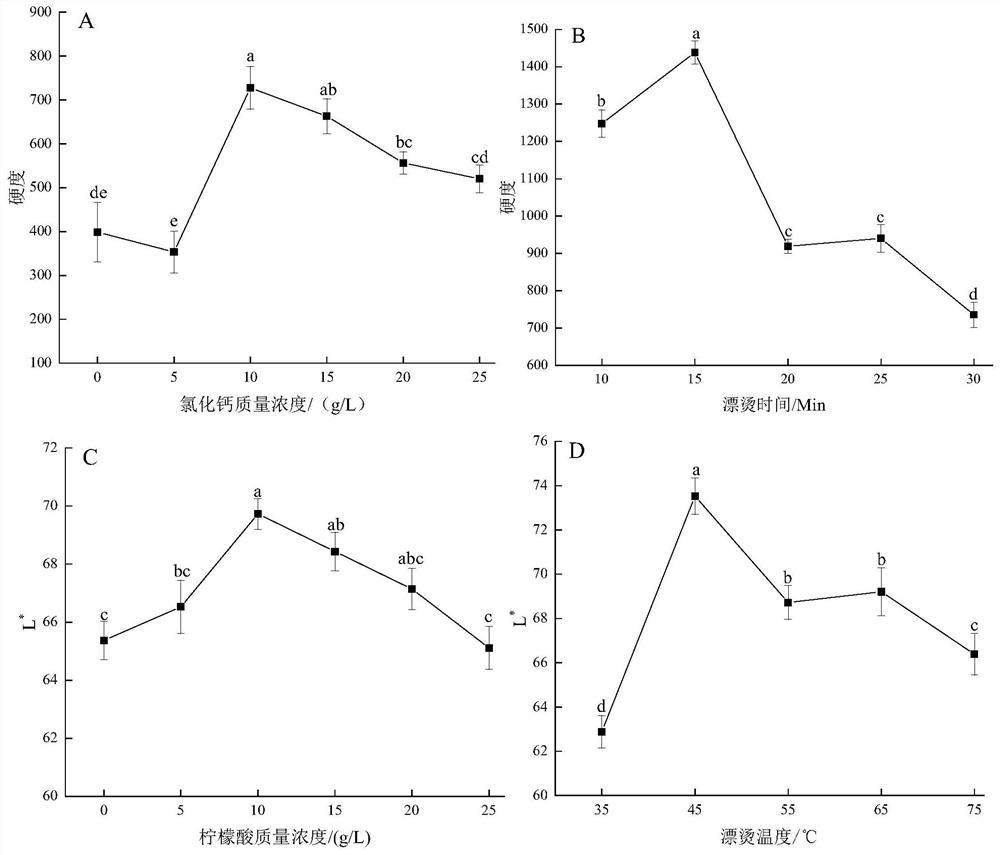

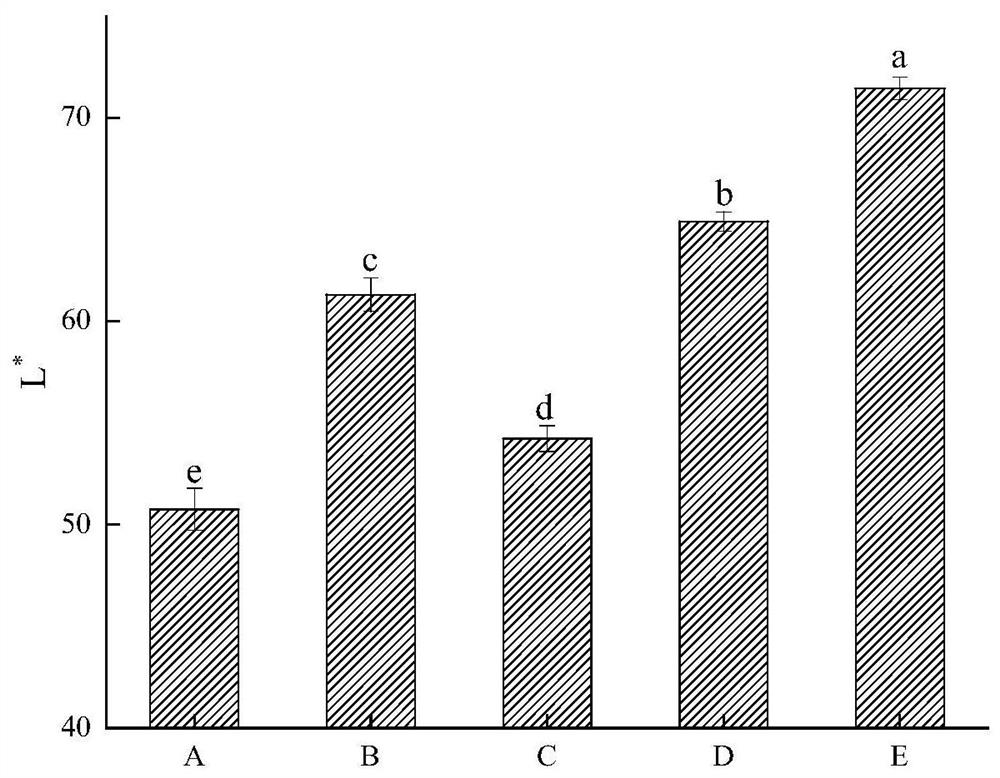

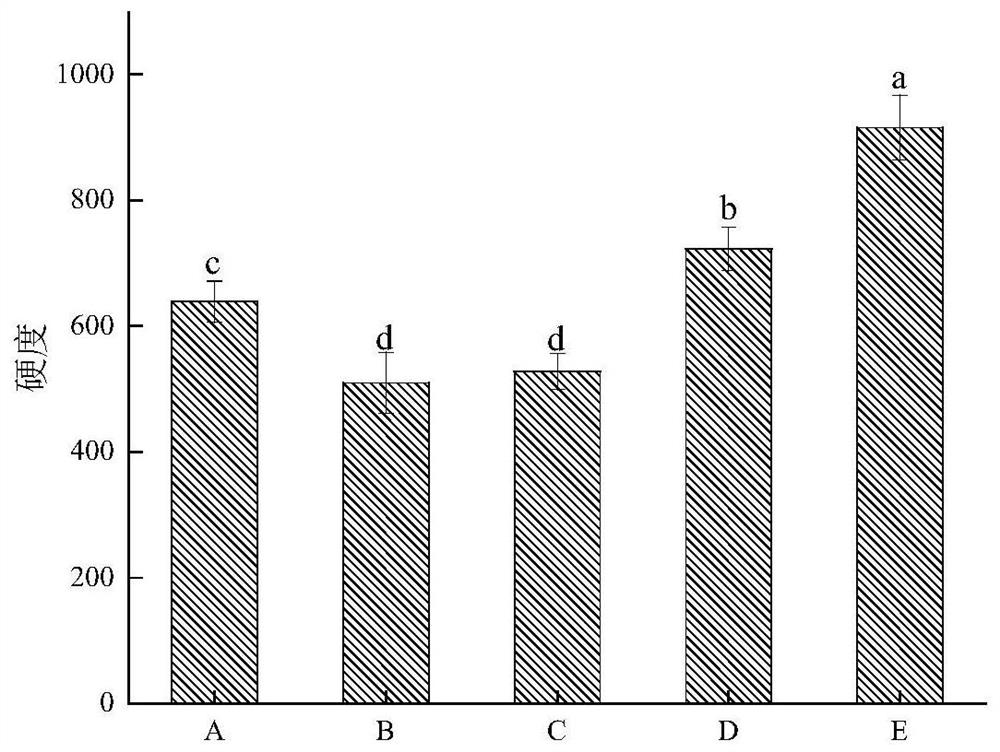

[0079] Step (2), low-temperature blanching: put Agaricus bisporus slices into the treatment solution (aqueous solution of 5g / L citric acid and 10g / L calcium chloride) according to the ratio of material to liquid 1:4 (g / ml), at 65°C Blanch for 15 minutes, turn over every 2 minutes;

[0080] Step (3), ultrasonic impregnation: put the treatment liquid soaked in the Agaricus bisporus slices into an ultrasonic device, 500W ultrasonic impregnation for 10 minutes, remove the Agaricus bisporus slices, rinse them with water for 3 times, and drain.

Embodiment 2

[0082] Preparation of Prefabricated Dishes with Stir-Fried Meat with Mushrooms Bisporus

[0083] Recipe: Agaricus bisporus 40kg, ham 15kg, green pepper 10kg, ginger 10kg, garlic 5kg, onion 1kg, cooking oil 10kg, salt 5kg, monosodium glutamate 0.5kg, soy sauce 0.5kg, cooking wine 0.5kg, sugar 0.5kg, water 5kg, Tert-butyl hydroquinone 0.01kg, nisin 0.01kg.

[0084] Step (1), wash the fresh Agaricus bisporus, cut into slices of about 1cm;

[0085] Step (2), according to the material-to-liquid ratio of 1:4 (g / mL), put the cut Agaricus bisporus into the treatment solution containing 5g / L citric acid and 10g / L calcium chloride at 65°C, and turn it every 2min Once, soak for 15 minutes;

[0086] Step (3), put the treatment liquid into the ultrasonic equipment, 500W immersion for 10 minutes, after the immersion is completed, remove the water and rinse 3 times, and drain naturally for 30 minutes;

[0087] Step (4), add edible oil to the hot pot in the automatic stir-frying machine, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com