Method for screening oil-producing filamentous fungi

A filamentous fungus and extraction method technology, applied in the field of microorganisms, can solve the problems of high efficiency and directional screening of oil-producing filamentous fungi, which cannot be done, and achieve the effect of improving the efficiency of obtaining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Preparation of selection medium

[0033] 1. Preparation of PDA medium (potato agar medium): 20 g of glucose, 4 g of potato extract, 20 g of agar, supplemented with deionized water to 900 mL, sterilized at 115° C. for 20 minutes, and set aside.

[0034] 2. Preparation of TTC (triphenyltetrazolium chloride) solution: Weigh 0.5g of TTC and add it to 95mL of deionized water, shake well, and set aside.

[0035] 3. Preparation of triclosan solution: Weigh 20 mg of triclosan drug powder, add 20 mL of absolute ethanol, fully dissolve, and prepare a triclosan solution with a mother liquor concentration of 1 mg / mL for use.

[0036] 4. Preparation of selection medium: Measure 5mL of triclosan mother liquor and 95mL of TTC (triphenyltetrazolium chloride) solution and add them to 900mL of PDA medium that has been sterilized, shake well, and make PDA The culture medium was prepared as a selection medium containing 5 mg / L triclosan and 0.5 g / L triphenyltetrazolium chloride...

Embodiment 2

[0037] Example 2: Screening Oleaginous Filamentous Fungi

[0038] 1. Collection of soil samples

[0039] Through the selection of chicken farms, orchards and rice fields in the Handan area, the soil samples were collected according to the surface soil sample collection method, and then quickly packed into ziplock bags, stored at low temperature and brought back to the laboratory. After the soil samples were naturally air-dried, the samples were analyzed and analyzed. Isolation of oleaginous filamentous fungi.

[0040] 2. Screening oleaginous filamentous fungi from soil samples

[0041] Take 1g of soil sample in 9mL of sterile aqueous solution, shake at 120r / min for 1h, and then serially dilute with physiological saline at a volume ratio of 1:10. take 10 -1 、10 -2 、10 -3 、10 -4 The bacteria solutions of the four dilution gradients were respectively coated on the corresponding selection medium, the oleaginous filamentous fungi were isolated, and the spores of the oleaginous ...

Embodiment 3

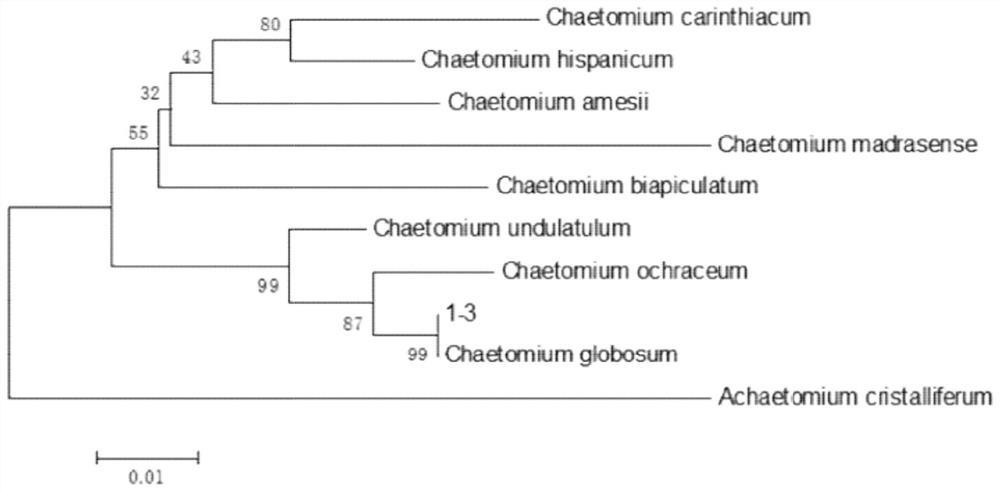

[0043] Example 3: Staining and preliminary identification of strain lipid particles

[0044] 1. Colony morphology observation

[0045] The isolated and purified strains were inoculated on potato dextrose agar medium, cultured at 28°C until a single colony was grown, and the colony morphological characteristics of the strains on the medium were observed.

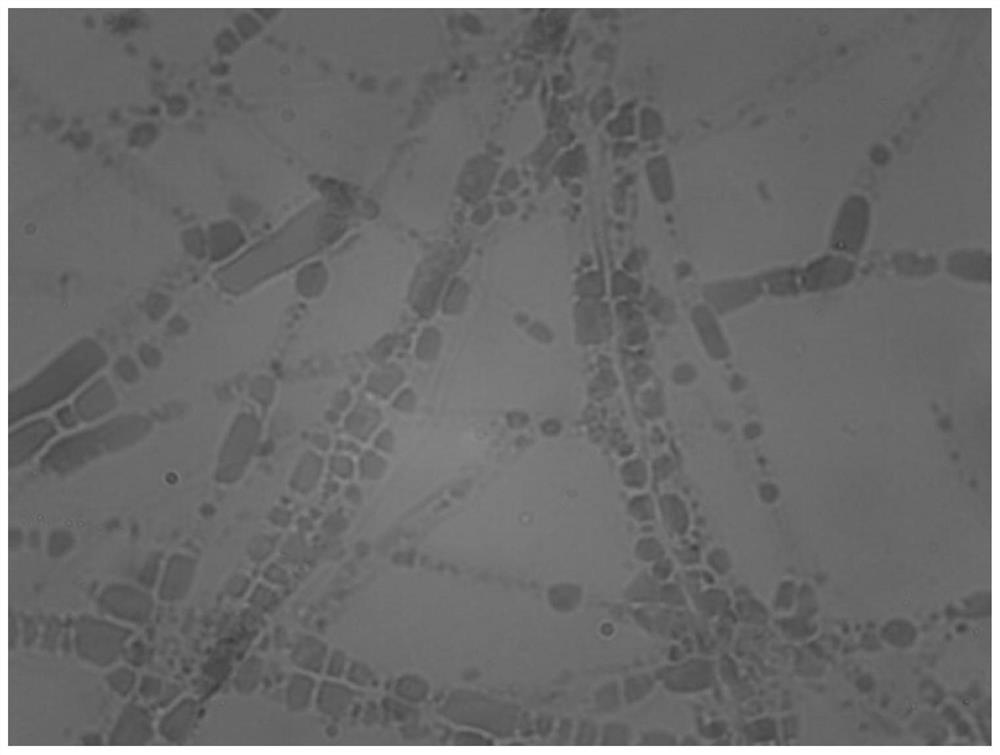

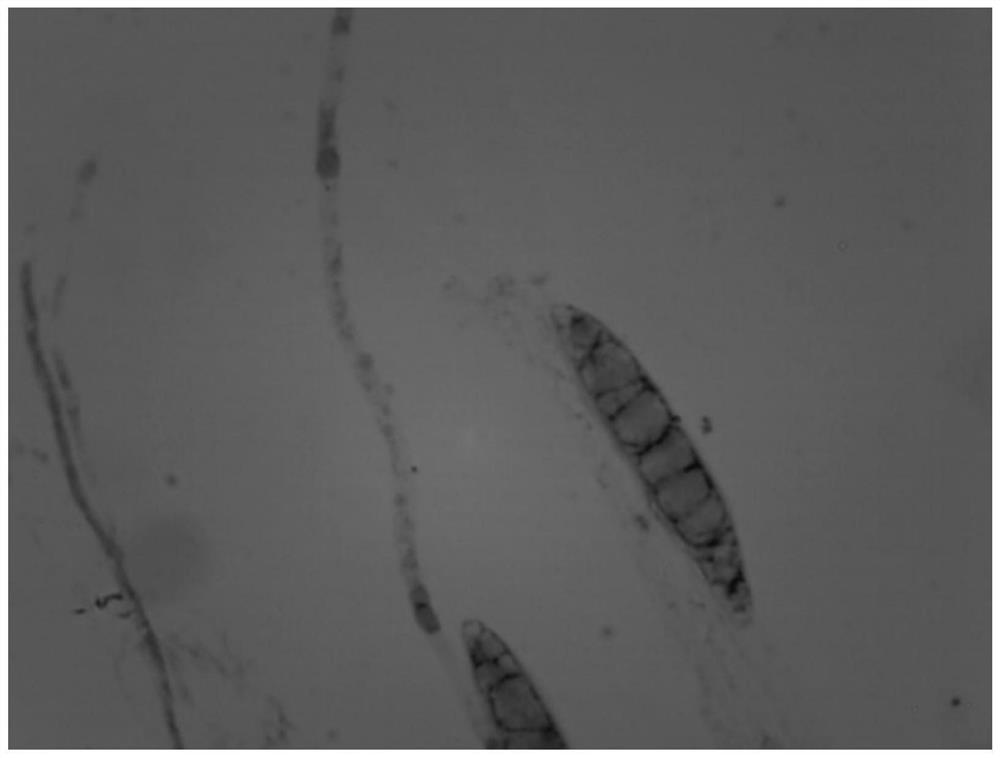

[0046] 2. Mycelia treatment

[0047] The 2 strains of filamentous fungi that were screened were picked up with tweezers in an aseptic operating table, rinsed with sterile water for a period of time, smashed and destroyed with glass rods, and made temporary slides.

[0048] 3. Grease granule dyeing

[0049] Take 40μL-60μL of 0.3% Sudan Black-B for staining for 10min, wash away the staining agent with water, blot the residual water on the glass slide with filter paper, then rinse with decolorant 75% alcohol until it is colorless, and use it after the slide is dry. Counterstain with safflower for 2 minutes, rinse the slides w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ion source temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com