Method and device for recovering polymetallic nodules

A polymetallic nodule and recovery method technology, which is applied in the field of polymetallic nodule recovery, can solve the problems of large consumption of leaching agents, low metal extraction rate, complicated purification of leaching solution, etc., to solve high acid consumption costs and reduce acid costs , Improve the effect of main metal extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

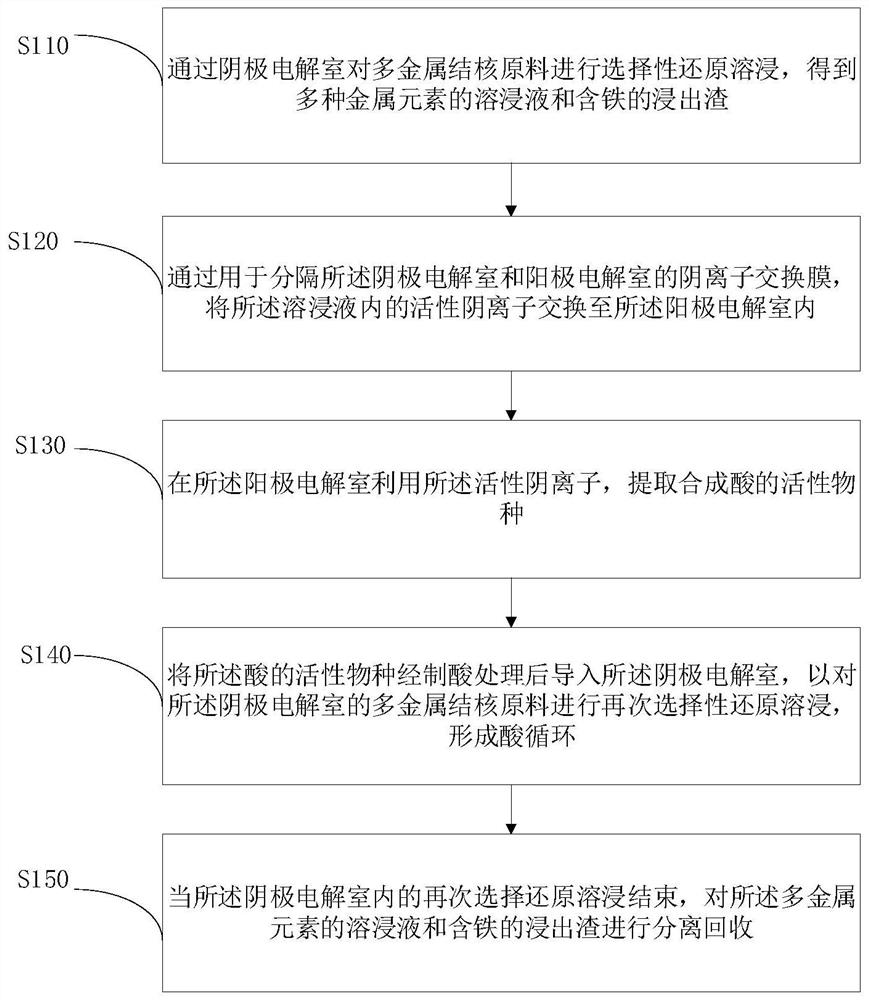

Method used

Image

Examples

Embodiment example 1

[0113] The chemical compositions of typical deep-sea polymetallic nodules are shown in Table 1.

[0114] element Mn Fe Ni Cu Co CaO content / % 21.75 10.78 1.34 1.54 0.24 1.57 element SiO 2

MgO Al 2 O 3

Na 2 O

K 2 O

P content / % 15.71 3.45 4.67 2.24 1.25 0.12

[0115] Table 1

[0116] The anolyte is an organic wastewater solution with high Cl content, and Cl in the wastewater - The concentration ratio is 5%.

[0117] The cathodic electrolysis chamber and the anodic electrolysis chamber are composed of Cl - Anions are separated by a membrane.

[0118] The deep-sea polymetallic nodules are finely ground to -0.074mm, accounting for 70%, and then added to the two electrode spaces in the cathode electrolysis chamber. The cathode electrode plate is a graphite felt conductive electrode, and the cathode electrolysis chamber is filled with a plurality of parallel electrodes of graphite felt electrodes and...

Embodiment example 2

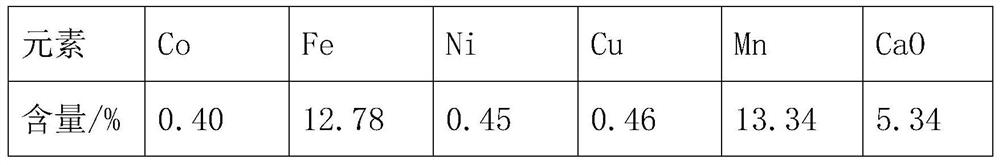

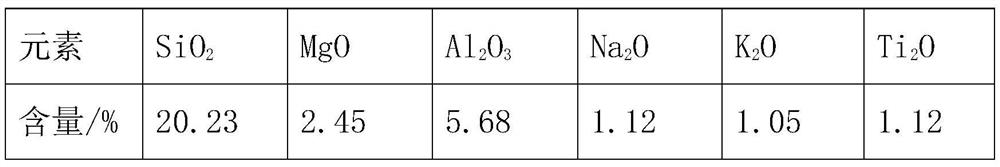

[0122] The chemical compositions of typical deep-sea cobalt-rich crusts are shown in Table 2.

[0123]

[0124]

[0125] Table 2

[0126] The anolyte is seawater that has been evaporated and concentrated by 1 times, in which Cl - The concentration ratio is 3.5%.

[0127] The cathodic electrolysis chamber and the anodic electrolysis chamber are composed of Cl - Anions are separated by a membrane.

[0128] The deep-sea cobalt-rich crusts are finely ground to -0.074mm, accounting for 65%, and then added to the two electrode spaces in the cathode electrolysis chamber. The cathode electrolysis chamber is equipped with a stirring device for stirring reduction and leaching, and the cathode and the anode are connected by a constant potential electrolysis device. The electrode plate of the electrolysis chamber is a graphite plate, the control voltage cathode reduction and leaching potential is -1.5V, and the current density in the process is between 30 ~ 50mA / cm 2 , the liqui...

Embodiment example 3

[0131] The chemical compositions of typical terrestrial cobalt-manganese polymetallic ores are shown in Table 3.

[0132] element Mn Fe Co Ni P content / % 27.12 16.55 0.12 0.22 0.51

[0133] table 3

[0134] Anolyte is wastewater with high organic concentration, in which COD cr The concentration is 20g / L, mainly bromine-containing aldehydes and phenolic organic pollutants.

[0135] The manganese-cobalt polymetallic oxide ore is finely ground to -0.074mm, accounting for 70%, and then added to the two electrode spaces in the cathode electrolysis chamber. The cathode electrolysis chamber is equipped with a stirring device for stirring reduction and leaching, and the cathode and the anode are connected by a constant potential electrolysis device. The electrode plate of the cathode electrolysis chamber is made of stainless steel mesh, the control voltage cathode reduction and leaching potential is -2.0V, and the current density in the process is be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com