High-salt industrial wastewater resource recovery treatment system and method

A technology for industrial wastewater and resource recovery, which is applied in water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. It can solve the problems that the hardness cannot meet the bipolar membrane, the influence of the electrolysis device, and the blocking of the membrane.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

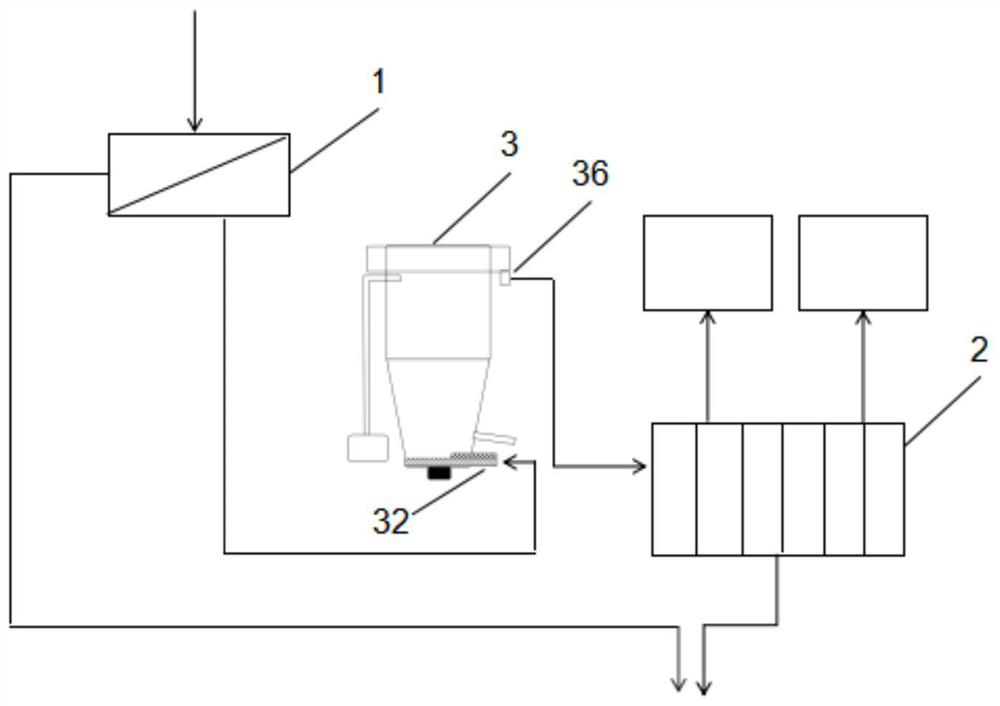

[0060] Such as figure 1 As shown, a high-salt industrial wastewater resource recovery treatment system includes a reverse osmosis device 1 and a bipolar membrane electrodialysis device 2, and an induced crystallization device 3 is arranged between the reverse osmosis device 1 and the bipolar membrane electrodialysis device 2;

[0061] Reverse osmosis device 1 is used for concentrating incoming water;

[0062] The bipolar membrane electrodialysis device 2 is used to hydrolyze and ionize water molecules to form recoverable acid and alkali;

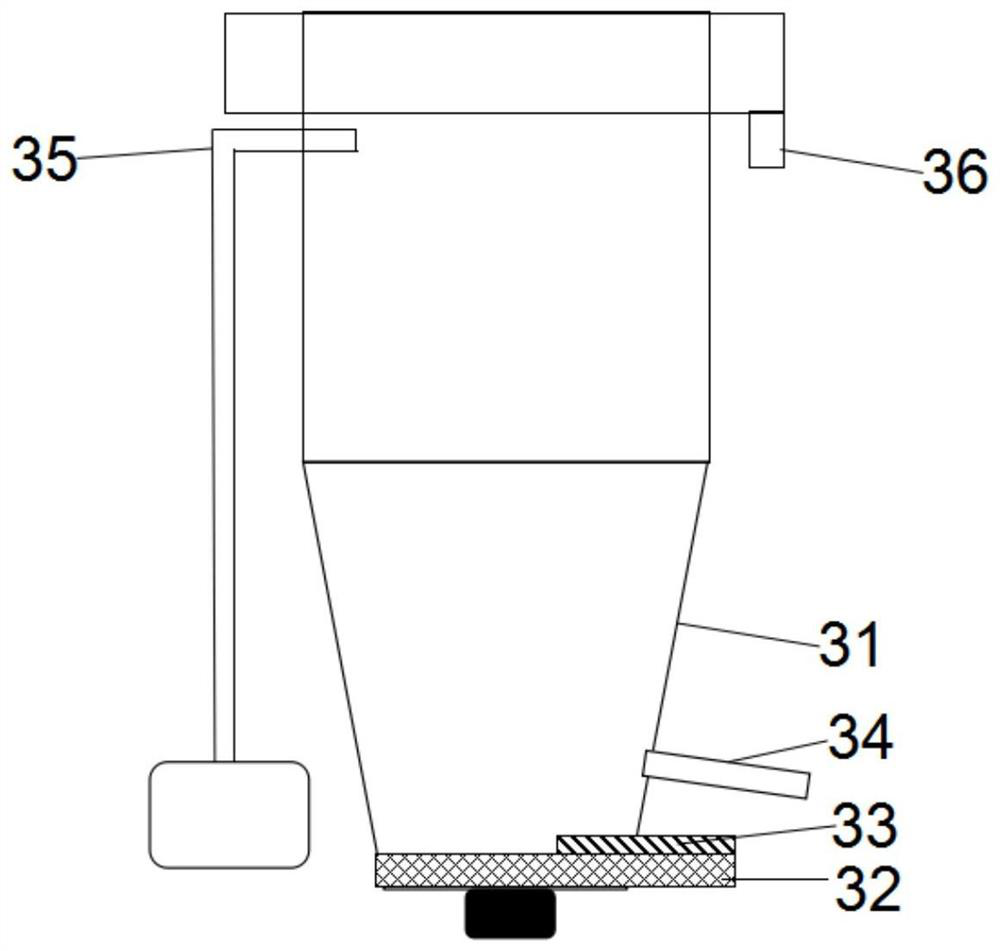

[0063] Such as figure 2 As shown, the induced crystallization device 3 includes a body 31, a water inlet 32 arranged at the bottom of the body 31, a dosing port 33, a crystal particle discharge port 34, a seed crystal injection port 35 arranged at the top side of the body 31, and a crystal seed injection port arranged at the body 31. The water outlet 36 on the side opposite to the seed crystal injection port 35 at the top; the dosing po...

Embodiment 2

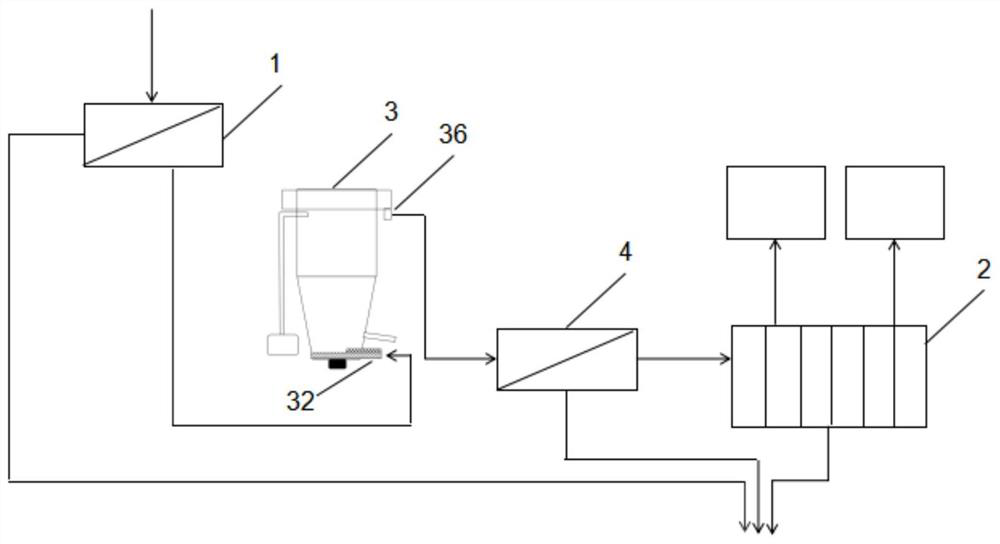

[0065] Such as image 3 As shown, a high-salt industrial wastewater resource recovery treatment system includes a reverse osmosis device 1 and a bipolar membrane electrodialysis device 2, an induced crystallization device 3 is arranged between the reverse osmosis device 1 and the bipolar membrane electrodialysis device 2, and the induced A second reverse osmosis device 4 is also arranged between the crystallization device 3 and the bipolar membrane electrodialysis device 2;

[0066] Reverse osmosis device 1 is used for concentrating incoming water;

[0067] The bipolar membrane electrodialysis device 2 is used to hydrolyze and ionize water molecules to form recoverable acid and alkali;

[0068] The induced crystallization device 3 includes a body 31, a water inlet 32 arranged at the bottom of the body 31, a dosing port 33, a crystal particle discharge port 34, a seed crystal insertion port 35 arranged at the top side of the body 31, and a crystal seed injection port 35 arra...

Embodiment 3

[0071] Such as Figure 4 As shown, a high-salt industrial wastewater resource recovery treatment system includes a reverse osmosis device 1 and a bipolar membrane electrodialysis device 2, an induced crystallization device 3 is arranged between the reverse osmosis device 1 and the bipolar membrane electrodialysis device 2, and the induced A second reverse osmosis device 4 is also arranged between the crystallization device 3 and the bipolar membrane electrodialysis device 2, and a water tank 5 is arranged between the second reverse osmosis device 4 and the bipolar membrane electrodialysis device 2;

[0072] Reverse osmosis device 1 is used for concentrating incoming water;

[0073] The bipolar membrane electrodialysis device 2 is used to hydrolyze and ionize water molecules to form recoverable acid and alkali;

[0074]The induced crystallization device 3 includes a body 31, a water inlet 32 arranged at the bottom of the body 31, a dosing port 33, a crystal particle discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com