Preparation method and device of methyl myristate

A technology for the preparation of methyl myristate and a device, which is applied in the field of preparation of methyl myristate, can solve the problems of difficult product separation and purification, strict acidity requirements, and difficult continuous production, and achieve easy product separation and purification, and increase production and quality, yield improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

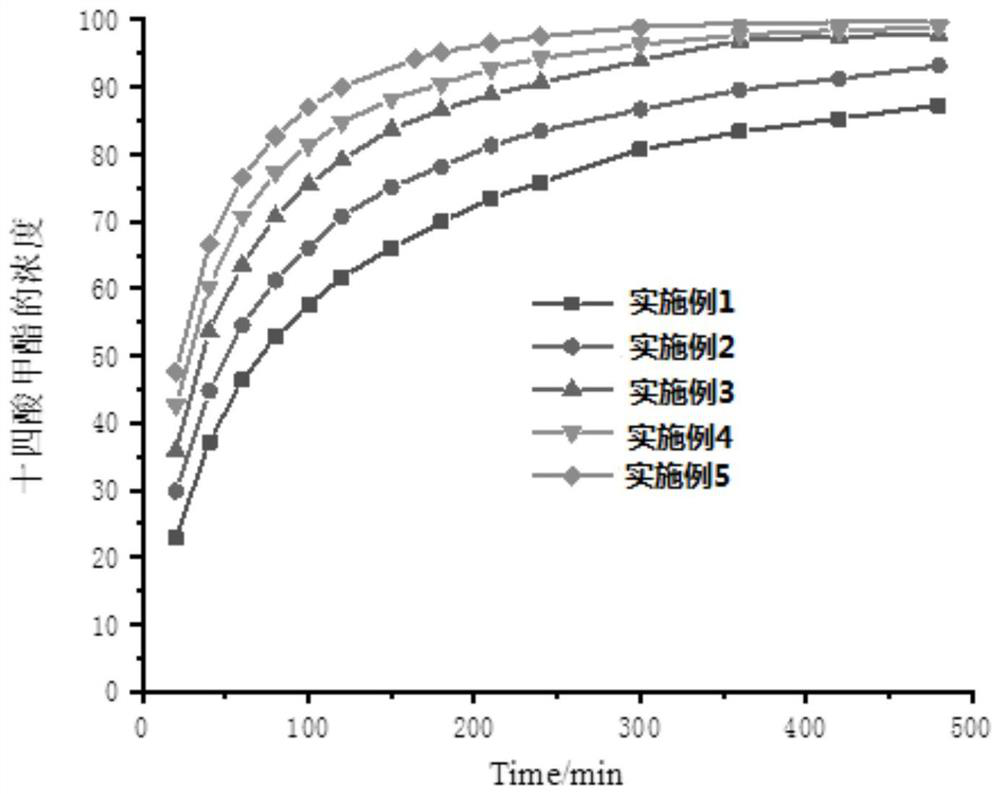

Embodiment 1

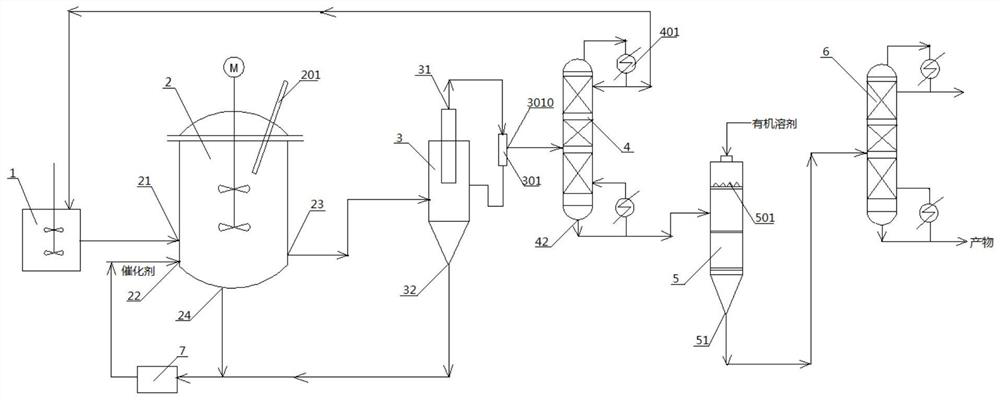

[0052] use figure 1 In the device shown, myristic acid and methanol are passed into the premixing tank 1 at a molar ratio of 1:5, stirred at a rate of 400rpm-600rpm until the myristic acid is completely dissolved to form a mixture, and then enter the full mixing tank from the raw material inlet 21 2 middle;

[0053] Simultaneously, the catalyzer Amberlyst 39wet of 10wt% of mixture quality is added in the fully mixed still 2 through catalyst inlet 22 and carry out esterification reaction, and the fully mixed still 2 is provided with temperature control device 201 and is used for controlling the temperature maintenance in the esterification reaction process At 50-60°C, the reaction is sampled at a certain time interval and analyzed by gas chromatography. The operating condition of the gas chromatograph is that the carrier gas is N 2 , pre-column pressure: 45.2kPa; makeup gas (N 2 ) flow: 30mL / min; H 2 : 40mL / min; air: 400mL / min; the temperature of the gasification chamber is ...

Embodiment 2

[0057] The operating steps of this embodiment are consistent with those of Embodiment 1, except that the catalyst Amberlyst 39wet of 15 wt% of the mass of the mixture is used.

Embodiment 3

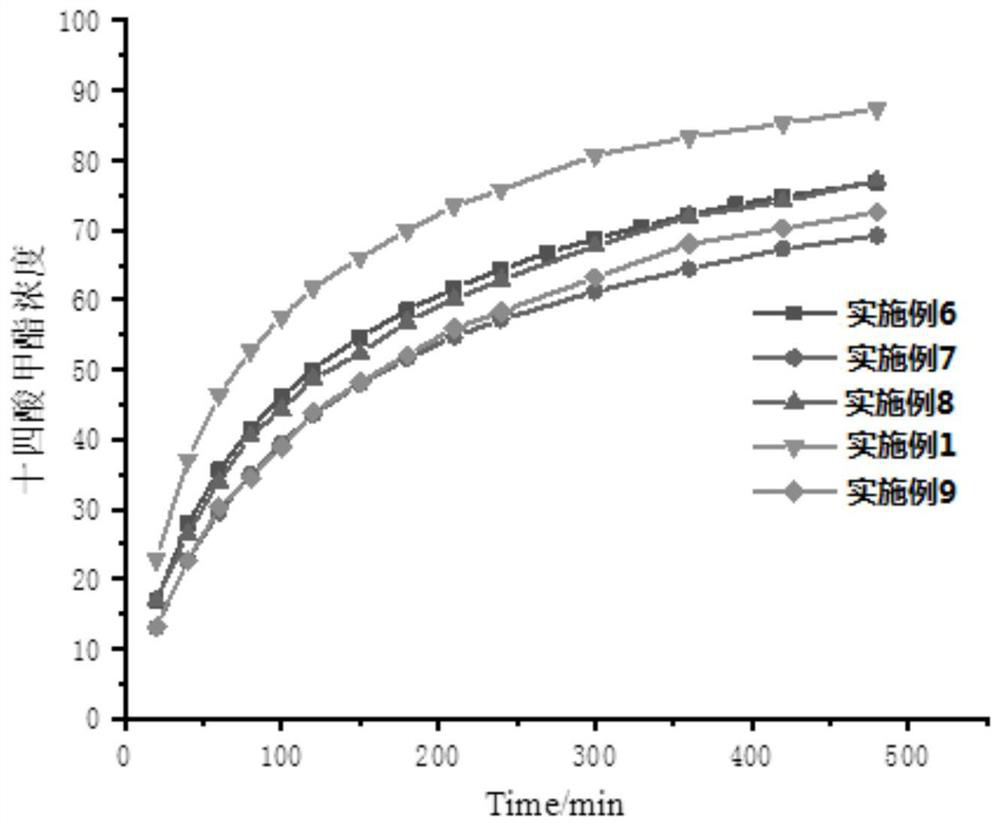

[0059] The operating steps of this example are the same as those of Example 1, except that 20 wt% of the catalyst Amberlyst 39wet is added to the mass of the mixture. The gas chromatogram of the specific product can be found in image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com