Preparation method of colorful building integrated photovoltaics (BIPV) thin-film solar cell

A solar cell, a colorful technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of loss of photoelectric conversion efficiency of cells, increase of production steps, increase of cost, etc., to ensure the overall structure and performance, and increase the utilization rate , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

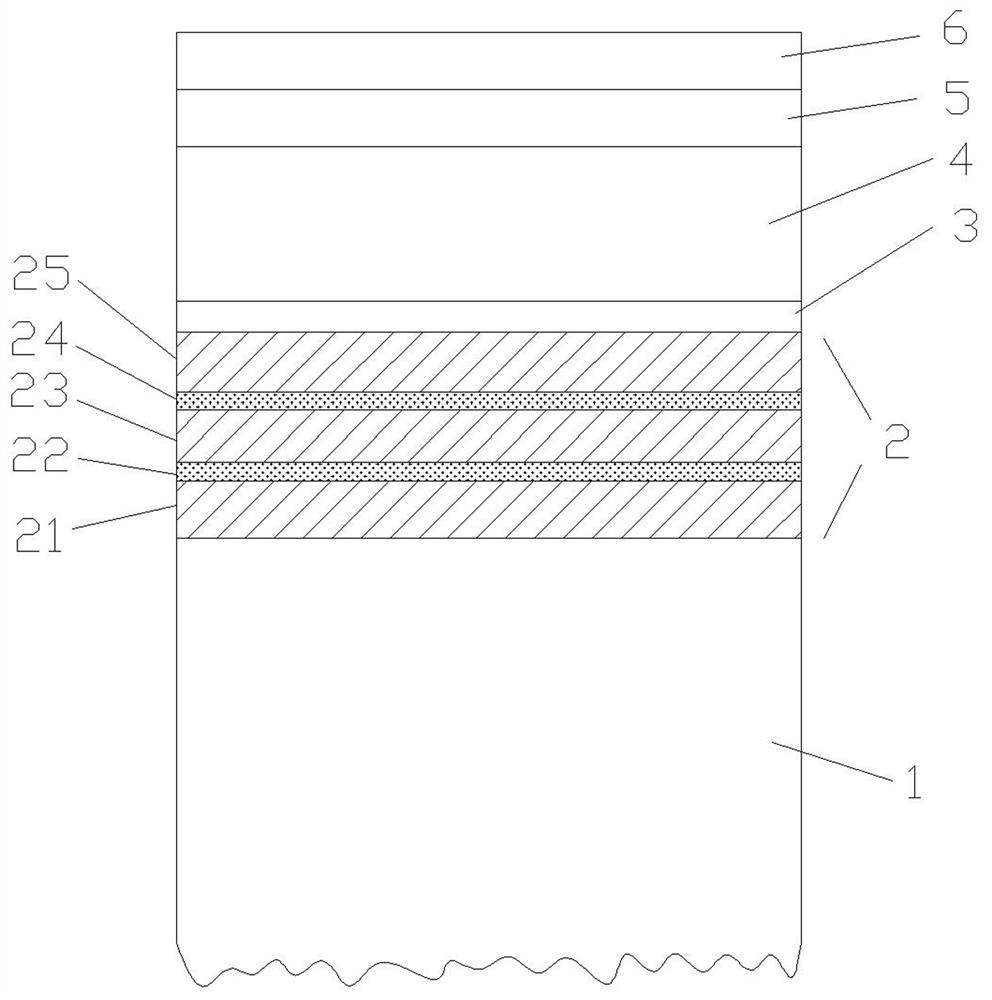

[0033] Such as figure 1 Shown, the invention provides a kind of preparation method of colorful BIPV thin film solar cell, comprises the following steps:

[0034] S1. Take ultra-clear float glass as the glass substrate 1, and use a low-energy ion source to pretreat the glass substrate to remove the gas and pollutants adsorbed on the surface of the glass substrate and activate the surface to increase the surface energy of the glass substrate and reduce the coating. The wetting angle between the layer and the glass substrate;

[0035] Specifically: the ion source sputtering method is adopted, the Ar gas flow rate is 40sccm, the glass substrate 1 is bombarded, the working pressure is 0.8Pa, the power is 30W, and the time is 20min;

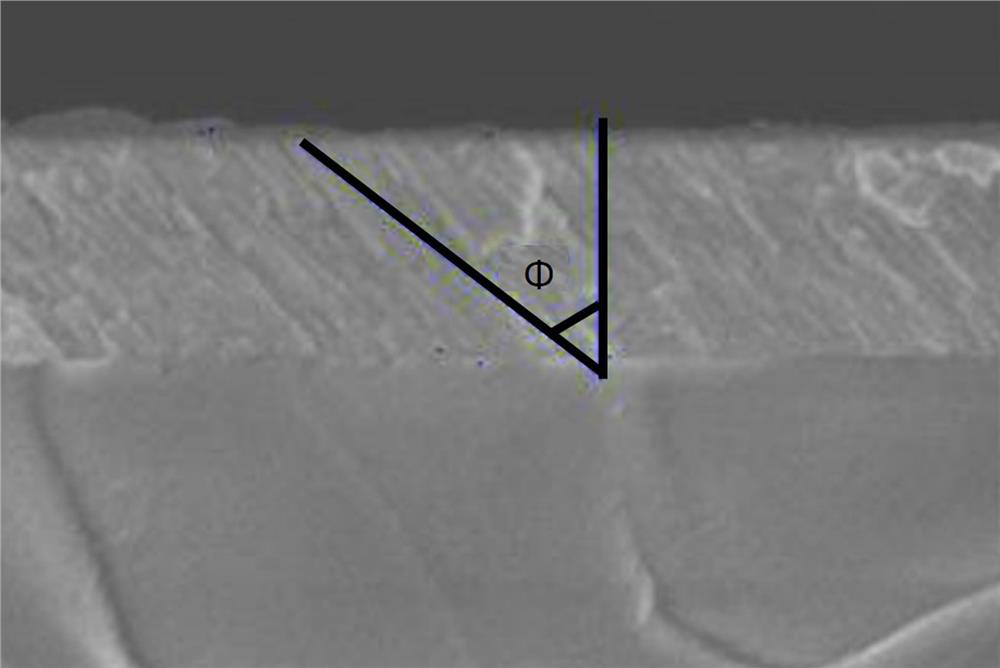

[0036] S2. Using a grazing angle magnetron sputtering process, a transparent conductive layer is deposited on the top surface of the glass substrate 1, and the transparent conductive layer is used as the color functional layer 2; the color functional ...

Embodiment 2

[0050] Such as figure 1Shown, the invention provides a kind of preparation method of colorful BIPV thin film solar cell, comprises the following steps:

[0051] S1. Take ultra-clear float glass as the glass substrate 1, and use a low-energy ion source to pretreat the glass substrate to remove the gas and pollutants adsorbed on the surface of the glass substrate and activate the surface to increase the surface energy of the glass substrate and reduce the coating. The wetting angle between the layer and the glass substrate;

[0052] Specifically: the ion source sputtering method is adopted, the Ar gas flow rate is 50sccm, and the glass substrate 1 is bombarded, the working pressure is 0.9Pa, the power is 40W, and the time is 15min;

[0053] S2. Using a grazing angle magnetron sputtering process, a transparent conductive layer is deposited on the top surface of the glass substrate 1, and the transparent conductive layer is used as the color functional layer 2; the color function...

Embodiment 3

[0067] Such as figure 1 Shown, the invention provides a kind of preparation method of colorful BIPV thin film solar cell, comprises the following steps:

[0068] S1. Take ultra-clear float glass as the glass substrate 1, and use a low-energy ion source to pretreat the glass substrate to remove the gas and pollutants adsorbed on the surface of the glass substrate and activate the surface to increase the surface energy of the glass substrate and reduce the coating. The wetting angle between the layer and the glass substrate;

[0069] Specifically: the ion source sputtering method is adopted, the Ar gas flow rate is 40sccm, and the glass substrate 1 is bombarded, the working pressure is 0.7Pa, the power is 20W, and the time is 30min;

[0070] S2. Using a grazing angle magnetron sputtering process, a transparent conductive layer is deposited on the top surface of the glass substrate 1, and the transparent conductive layer is used as the color functional layer 2; the color functio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com