A breathable and waterproof multi-response fabric sensor

A fabric sensor, breathable and waterproof technology, used in instruments, scientific instruments, surface/boundary effects, etc., can solve problems such as performance degradation, and achieve mild and controllable reaction conditions, simple preparation process, and stable strain and temperature sensing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Preparation of MXene:

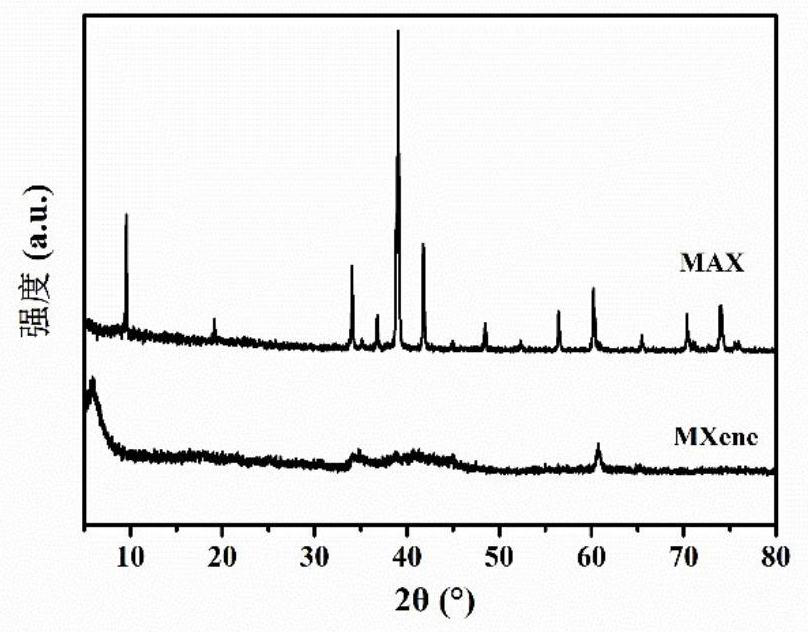

[0039] 1 g of LiF and 20 ml of dilute hydrochloric acid (9M) were stirred well for 15 min, followed by 1 g of Ti 3 AlC 2 The powder was added slowly, and the stirring was continued at 35 °C for 24 h until the etching was complete. Then the obtained MXene mixture was centrifuged and washed for 5 min at 3500 rpm with deionized water until the pH of the supernatant was greater than or equal to 6. The supernatant and the precipitate were mixed and sonicated for 1 h, then centrifuged at 3500 rpm for 1 h, and the upper layer of black liquid was collected, which was the MXene colloidal solution. figure 2 From the XRD patterns of MXene and MAX prepared for this example, it can be seen that the Al layer is completely etched, and the MXene is completely etched.

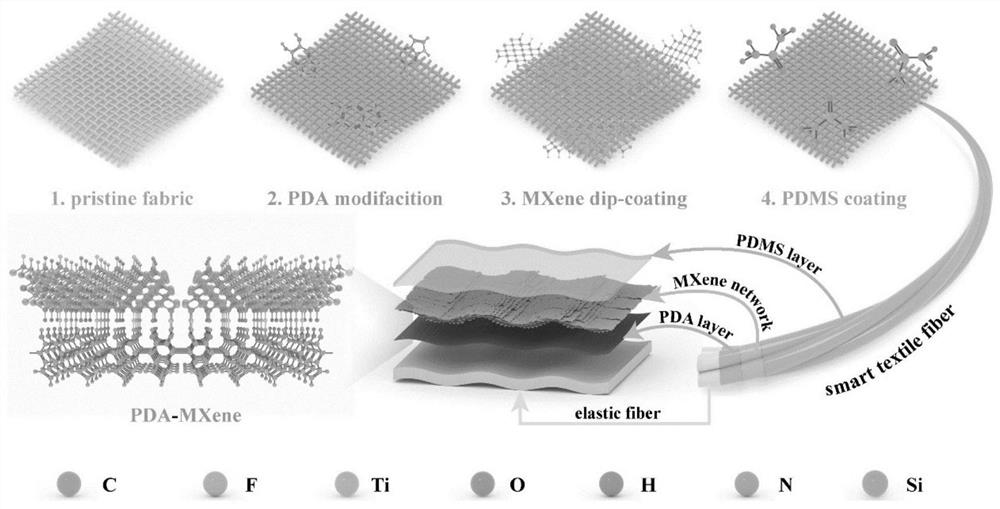

[0040] (2) Preparation of multifunctional MXene fabric sensor:

[0041] Put 0.24 g of Tris powder and 0.4 g of dopamine into 200 ml of deionized water and mix thoroughly, then put the flexi...

Embodiment 2

[0044] (1) Preparation of MXene:

[0045] The preparation process and its conditions are the same as step (1) of Example 1.

[0046] (2) Preparation of multifunctional MXene fabric sensor:

[0047] Put 0.24 g of Tris powder and 0.4 g of dopamine into 200 ml of deionized water and mix thoroughly, then put the flexible elastic fabric into the above solution for 6 h with magnetic stirring and react for 6 h. After the end, take it out and wash it fully with deionized water, and place it in a 40°C oven Dry for 12 h. The PDA-modified elastic fabric was immersed in the MXene colloid solution with a concentration of 5 wt.% for 10 minutes, the fabric was taken out and dried at 40 °C for 30 minutes, and then the above dipping and drying process was repeated twice to make MXene-impregnated three times fabric. In order to endow the fabric with superhydrophobic properties and maintain the inherent air permeability of the fabric itself, the fabric impregnated with MXene three times was i...

Embodiment 3

[0050] (1) Preparation of MXene:

[0051] The preparation process and its conditions are the same as step (1) of Example 1.

[0052] (2) Preparation of multifunctional MXene fabric sensor:

[0053] Put 0.24 g of Tris powder and 0.4 g of dopamine into 200 ml of deionized water and mix thoroughly, then put the flexible elastic fabric into the above solution for 6 h with magnetic stirring and react for 6 h. After the end, take it out and wash it fully with deionized water, and place it in a 40°C oven Dry for 12 h. The elastic fabric modified by PDA was immersed in the MXene colloidal solution with a concentration of 5 wt.% for 10 minutes, the fabric was taken out and dried at 40°C for 30 minutes, and then the dipping and drying process was repeated 4 times to prepare the fabric impregnated 5 times with MXene . In order to endow the fabric with superhydrophobic properties and maintain the inherent air permeability of the fabric itself, the fabric impregnated with MXene 5 times ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com