Photoelectric detector and preparation method thereof

A photodetector and electrode technology, used in electrolytic capacitor manufacturing, capacitors, photovoltaic power generation, etc., can solve the problems of poor environmental stability of photodetectors, poor environmental stability of black phosphorus nanosheets, and high process conditions, and achieve photoelectric detection performance. It has the effects of breakthrough in stability and performance, good environmental stability, and simple and easy-to-operate preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The second aspect of the present invention provides a Bi 2 Te 3 The preparation method of nano sheet, comprises the following steps:

[0056] Bi(NO 3 ) 3 ·5H 2 O and Na 2 TeO 3 Dissolve in the solvent, continue to add PVP to the solvent, stir for 10-100min to form a homogeneous mixture, the Bi(NO 3 ) 3 ·5H 2 O, Na 2 TeO 3 The ratio of the amount of substance to PVP is 1000:1000~5000:0.5~5;

[0057] Transfer the mixed solution to an autoclave, adjust the temperature of the autoclave to 170-190°C and react for 2-12 hours, quench to room temperature, centrifuge and dry the reactant to obtain Bi 2 Te 3 Nanosheets.

[0058] As a preferred embodiment, the Bi(NO 3 ) 3 ·5H 2 O, Na 2 TeO 3 The ratio of the amount of substance to PVP is 1000:2000:1.5, and the stirring time is 30min.

[0059] As a preferred embodiment, the autoclave is a polytetrafluoroethylene-lined autoclave, and the temperature of the autoclave is adjusted to 180°C.

[0060] As a preferred e...

Embodiment 1

[0105] A Bi 2 Te 3 The preparation method of nano sheet, comprises the following steps:

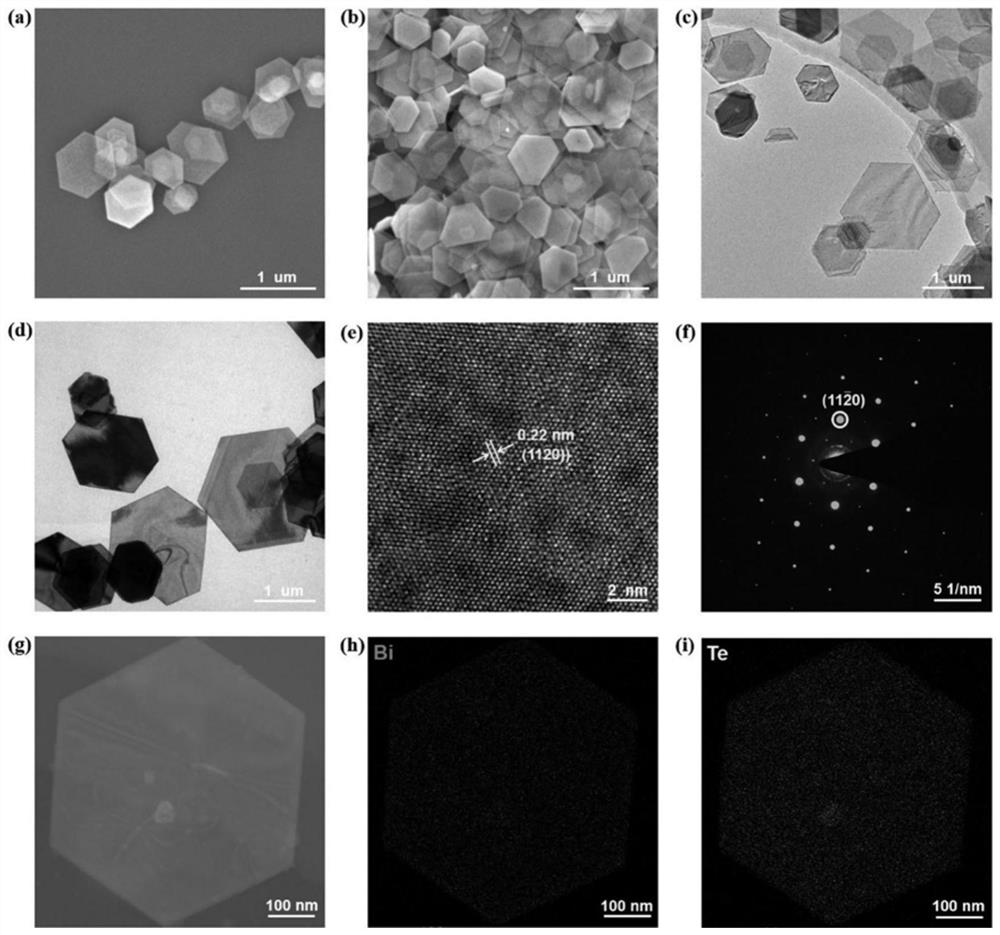

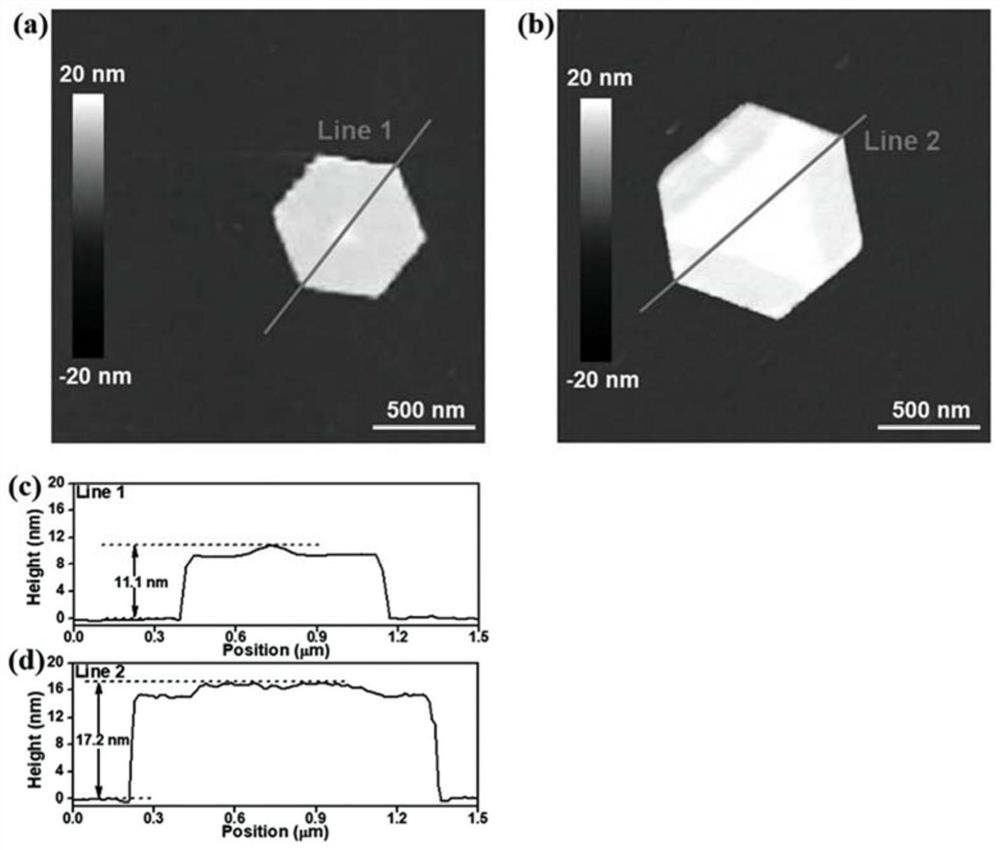

[0106] 20mmol of Bi(NO 3 ) 3 ·5H 2 O and 40 mmol Na 2 TeO 3 First dissolved in 30 mL of deionized water, then 0.03 mmol of PVP was added to the solution and kept stirring for 30 min to form a homogeneous mixture. Transfer the mixture to a 50 mL Teflon-lined autoclave and place in an oven at 180 °C. The reaction time is 2 hours, and the reactant is quenched to room temperature through the system to stop. Finally, the obtained reactant was centrifuged and vacuum-dried to obtain Bi 2 Te 3 nanosheets (called NP-1 samples). Such as figure 1 Shown in a, is the scanning electron microscope (SEM) image of NP-1 sample, figure 1 a and figure 1 g shows that the lateral dimensions of NP-1 nanosheets range from 470 to 770 nm. Such as figure 1 Shown in c is the transmission electron microscope (TEM) characterization pattern of the NP-1 sample, showing that the prepared Bi 2 Te 3 The na...

Embodiment 2

[0108] A Bi 2 Te 3 The preparation method of nano sheet, comprises the following steps:

[0109] 20mmol of Bi(NO 3 ) 3 ·5H 2 O and 40 mmol Na 2 TeO 3 First dissolved in 30 mL of deionized water, then 0.03 mmol of PVP was added to the solution and kept stirring for 30 min to form a homogeneous mixture. Transfer the mixture to a 50 mL Teflon-lined autoclave and place in an oven at 180 °C. The reaction time is 12 hours, and the reactant is quenched to room temperature through the system to stop. Finally, the obtained reactant was centrifuged and vacuum-dried to obtain Bi 2 Te 3 nanosheets (called NP-2 samples). Such as figure 1 Shown in b, is the scanning electron microscope (SEM) image of NP-2 sample, figure 1 b shows that the lateral dimensions of NP-2 nanosheets range from 520 to 940 nm. Such as figure 1 Shown in d is the transmission electron microscope (TEM) characterization pattern of the NP-2 sample, showing that the prepared Bi 2 Te 3 The nanosheets are he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com