Multi-component composite negative electrode material, preparation method thereof and lithium ion battery

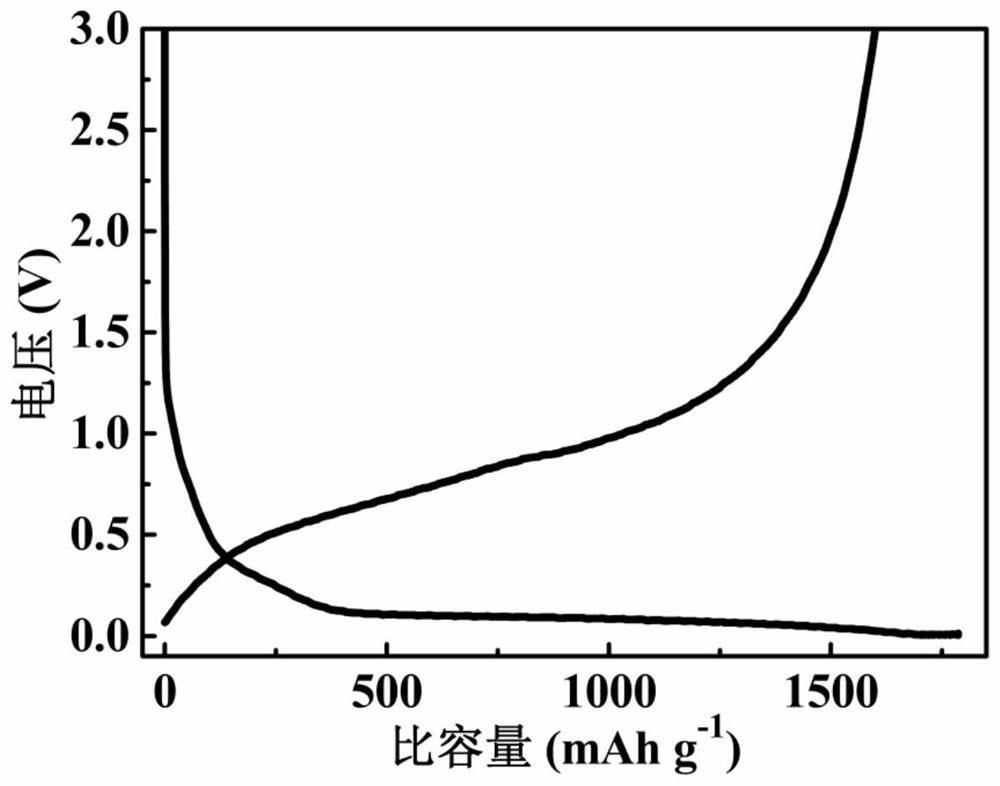

A negative electrode material, multi-component composite technology, applied in the direction of negative electrode, battery electrode, secondary battery, etc., can solve the problems of poor effect, achieve high first-time Coulombic efficiency, reduce the formation of SEI film, and increase the ion and electron transmission rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] In this embodiment, the multi-element composite negative electrode material is prepared according to the following method:

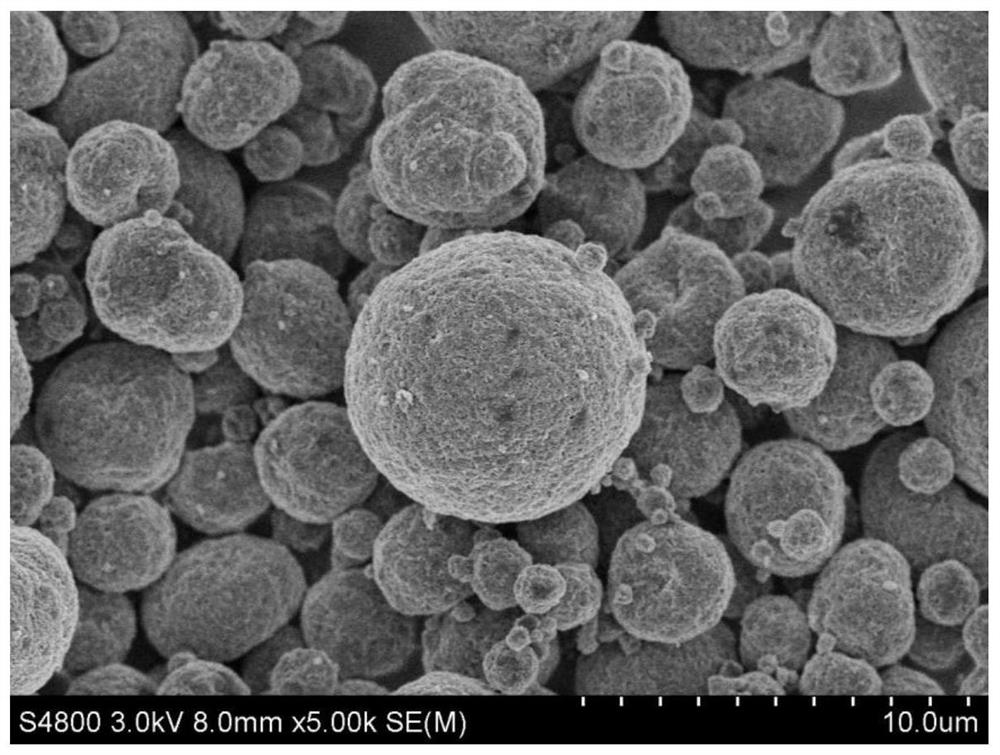

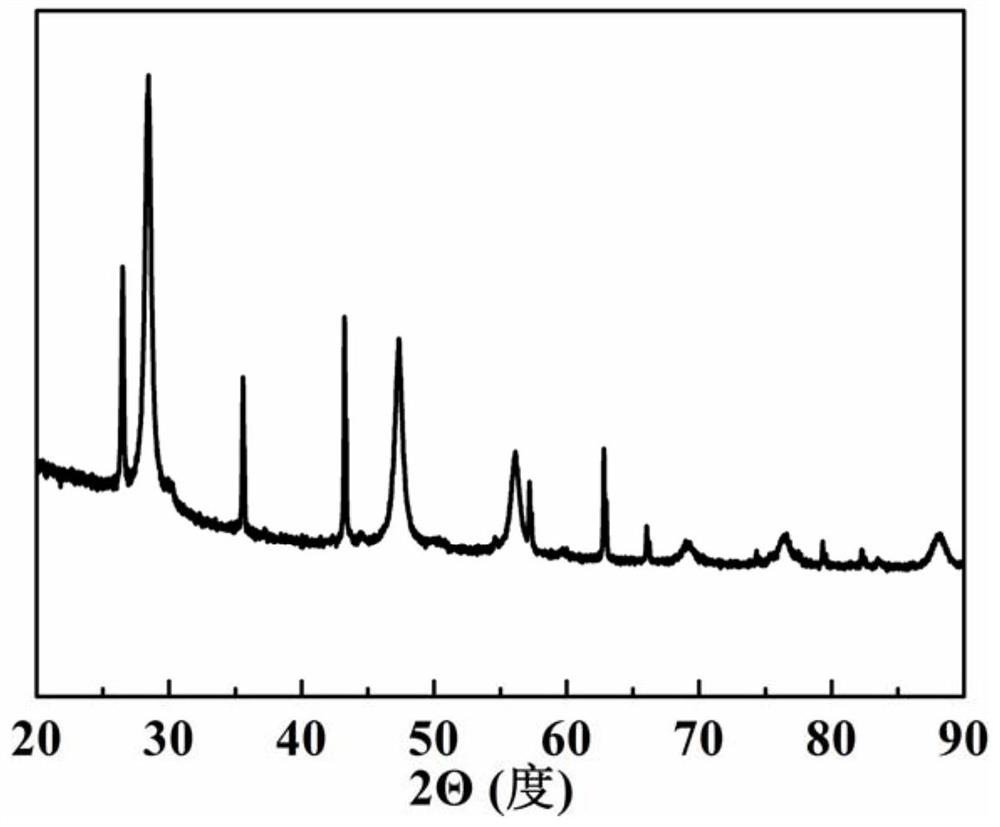

[0075] (1) Mechanically pulverize flake natural graphite to graphite particles with a median particle size of 10.0-30.0 μm, place it in a ball mill containing 0.01mm zirconia balls and ethylene glycol solvent, and perform ball milling to obtain the median Hollow graphite with a particle size of 1.0-15.0 μm.

[0076] (2) Disperse nano-silicon with a median particle size of 100nm and tetrabutyl titanate at a molar ratio of 4:1 in an ethanol solvent, and after ultrasonic stirring for 0.5h, slowly add the molar ratio of tetrabutyl titanate to the solution It is 1:4 deionized water, after continuing to stir for 20min, add lithium acetate and hollow graphite successively therein, control lithium acetate: tetrabutyl titanate: nano-silicon: the molar ratio of hollow graphite is 0.4:0.5:2: 2. Ultrasonic stirring for 0.5 hours to form a uniform suspension,...

Embodiment 2

[0083] In this embodiment, the multi-element composite negative electrode material is prepared according to the following method:

[0084] (1) Mechanically pulverize flake natural graphite to graphite particles with a median particle size of 10.0-30.0 μm, place it in a ball mill containing 0.01mm zirconia balls and ethylene glycol solvent, and perform ball milling to obtain the median Hollow graphite with a particle size of 1.0-15.0 μm;

[0085] (2) Disperse nano-silicon with a median particle size of 100nm and tetrabutyl titanate in a molar ratio of 4:1 in isopropanol solvent, stir ultrasonically for 0.5h, and slowly add tetrabutyl titanate dropwise into the solution Molar ratio is the deionized water of 1:4, after continuing to stir for 20min, add lithium hydroxide and hollow graphite successively wherein, control lithium hydroxide: tetrabutyl titanate: nano-silicon: the mol ratio of hollow graphite is 0.4: 0.5:2:2, ultrasonically stirred for 0.5h to form a uniform suspensi...

Embodiment 3

[0091] In this embodiment, the multi-element composite negative electrode material is prepared according to the following method:

[0092] (1) Mechanically pulverize flake natural graphite to graphite particles with a median particle size of 20.0-45.0 μm, place it in a ball mill containing 0.01 mm zirconia balls and ethylene glycol solvent, and perform ball milling to obtain the median Hollow graphite with a particle size of 5.0-20.0 μm.

[0093] (2) Disperse nano-silicon with a median particle size of 150nm and tetraisopropyl titanate in a molar ratio of 1:1 in ethylene glycol solvent, stir ultrasonically for 0.5h, and slowly add tetrabutyl titanate dropwise into the solution Deionized water with an ester molar ratio of 1:4, continue to stir for 20 minutes, and then add lithium hydroxide and hollowed graphite to it in turn, and control the molar ratio of lithium hydroxide: tetrabutyl titanate: nano-silicon: hollowed graphite to 0.4 :0.5:2:1.5, ultrasonically stirred for 0.5h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com