Manufacturing method of contact layer, semiconductor laser and manufacturing method of semiconductor laser

A manufacturing method and laser technology, applied in the direction of semiconductor lasers, lasers, laser parts, etc., to achieve the effect of not easy to fall off, good conductivity, and firm adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

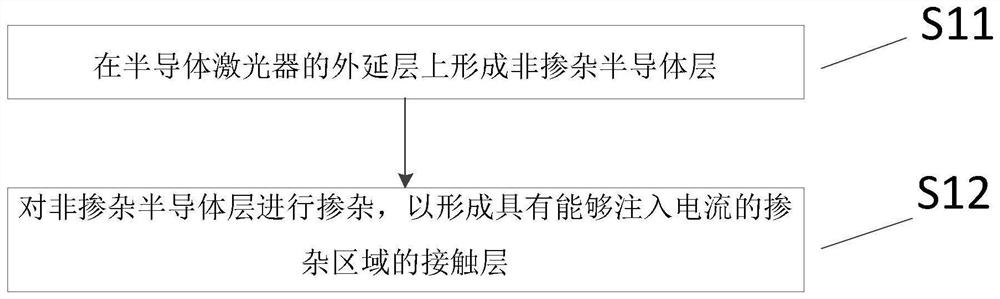

[0051] This embodiment provides a method for manufacturing a contact layer of a semiconductor laser, such as figure 1 with figure 2 shown, including the following steps:

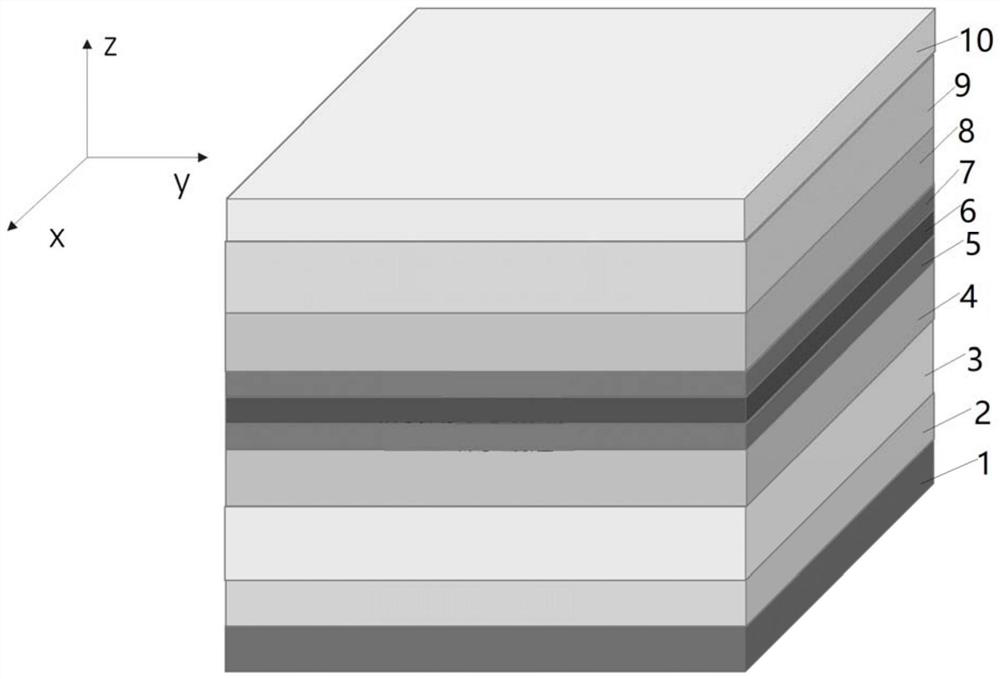

[0052] S11: forming a non-doped semiconductor layer on the epitaxial layer of the semiconductor laser. Specifically, a non-doped GaAs semiconductor layer is grown on the epitaxial layer of the semiconductor laser in a Metal-organic Chemical Vapor Deposition (MOCVD) device, such as image 3 As shown, for example, the non-doped GaAs semiconductor layer has a thickness of 400 nm.

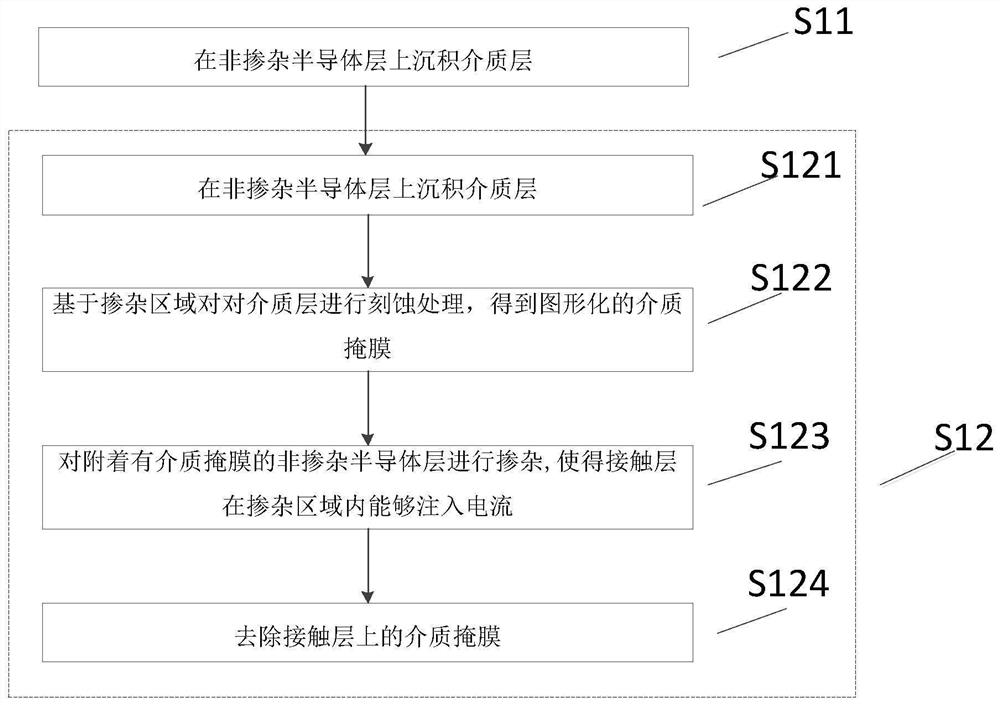

[0053] S12: Doping the non-doped semiconductor layer to form a contact layer having a doped region 101 capable of injecting current. Along the cavity length direction (ie Image 6 The y-axis direction in ) divides the doped region 101 into several sections, and the area of the small doped region 101 in each section is the area capable of injecting current in the doped region 101 . The area capable of injecting current in the ...

Embodiment 2

[0065] This embodiment provides a method for manufacturing a semiconductor laser, comprising the following steps:

[0066] S21: Generating an epitaxial layer of the semiconductor laser. Specifically, an N-type GaAs (gallium arsenide) substrate 1 is first grown in the MOCVD equipment, and then an N-type GaAs buffer layer 2 and an N-type AlGaAs (aluminum gallium arsenide) lower limit layer are sequentially grown on the N-type GaAs substrate 1 . Layer 3, N-type AlGaAs lower waveguide layer 4, GaAs quantum barrier layer 5, InGaAs (indium gallium arsenide) quantum well layer 6, GaAs quantum barrier layer 7, P-type AlGaAs upper waveguide layer 8, P-type AlGaAs upper confinement layer 9 , the epitaxial layer includes the above layers except the N-type GaAs substrate 1 .

[0067] S22: Using the manufacturing method described in Embodiment 1 to generate a contact layer to obtain a semiconductor laser structure including the contact layer. The semiconductor laser structure includes an...

Embodiment 3

[0073] This embodiment provides a semiconductor laser, see Figure 7 , which includes a semiconductor laser structure, electrodes formed on the upper and lower surfaces of the semiconductor laser structure, and anti-reflection films 132 and anti-reflection films 131 on the left and right sides of the semiconductor laser structure.

[0074] Wherein, the semiconductor laser structure includes an N-type GaAs substrate 1, an epitaxial layer and a contact layer. The epitaxial layer includes N-type GaAs buffer layer 2, N-type AlGaAs lower confinement layer 3, N-type AlGaAs lower waveguide layer 4, GaAs quantum barrier layer 5, InGaAs quantum well layer 6, GaAs quantum barrier layer 7, and P-type AlGaAs upper waveguide layer 8 and P-type AlGaAs upper confinement layer 9.

[0075] The electrodes include a P electrode 122 and an N electrode 121 , the P electrode 122 is located under the N-type GaAs substrate 1 , and the N electrode 121 is located above the GaAs contact layer 10 .

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com