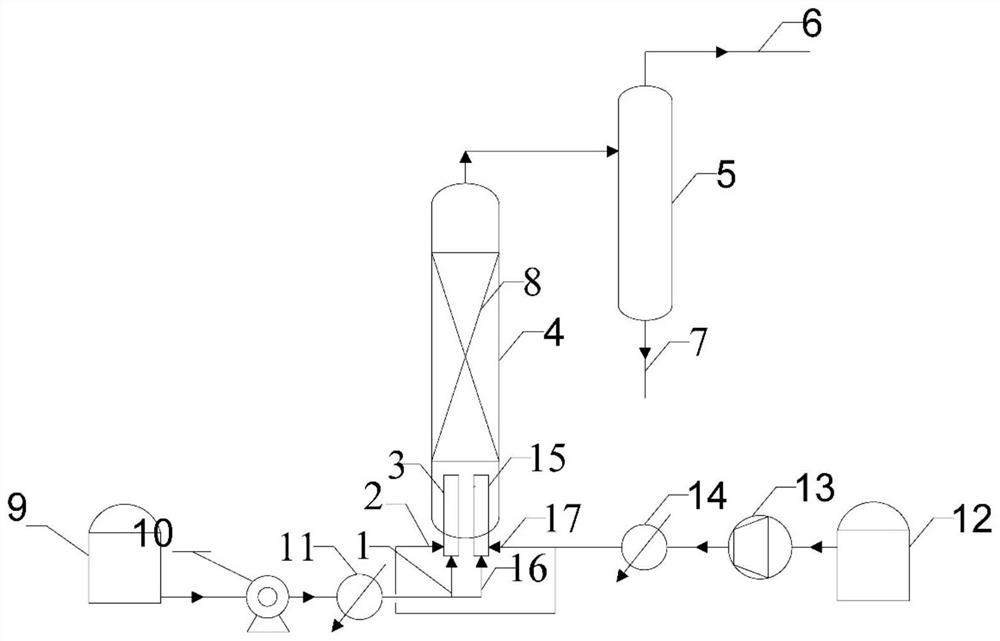

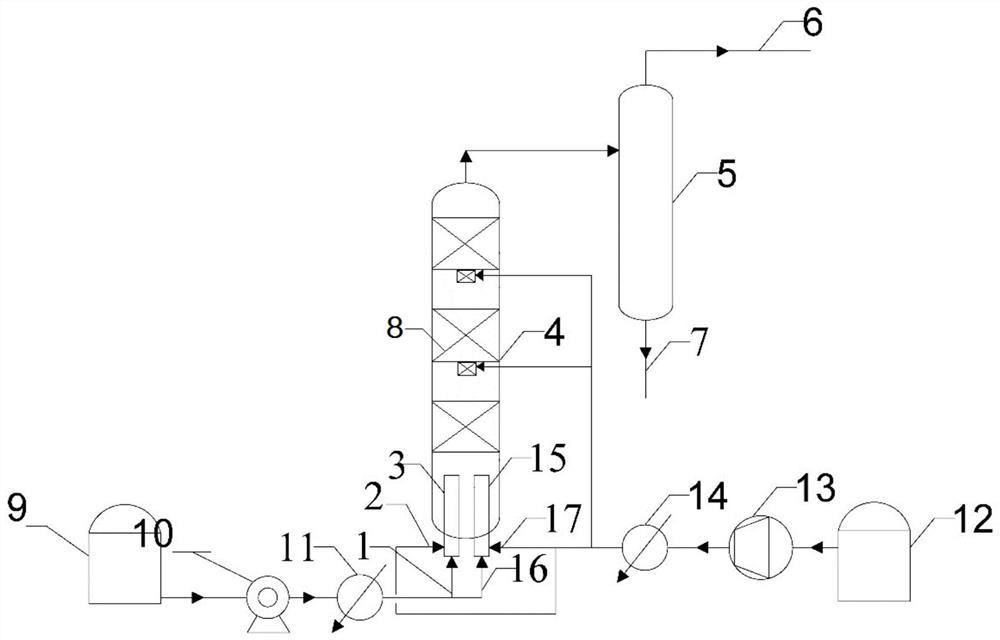

Ascending type fixed bed oil product hydrogenation micro-interface enhanced reaction system

A fixed-bed reactor and reaction system technology, applied in the petroleum industry, hydrocarbon oil treatment, chemical instruments and methods, etc., can solve the problems of insufficient reaction energy consumption, small contact area, etc. Good effect of responsiveness and independence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Fresh hydrogen and gasoline pass through the gas phase inlet 2 of the gas-liquid linkage micro-interface generator and the liquid phase inlet 1 of the gas-liquid linkage micro-interface generator respectively at a standard volume ratio of 0.25:1, and enter the fixed-bed reactor 4 under the shell. In the gas-liquid linkage type micro-interface generator 3, the other path enters the gas-type micro-interface generator 15 through the gas phase inlet 17 of the pneumatic micro-interface generator and the liquid phase inlet 16 of the pneumatic micro-interface generator respectively at a standard volume ratio of 800:1 middle. Under the action of the gas-liquid linkage micro-interface generator 3 and the pneumatic micro-interface generator 15, the hydrogen is broken into microbubbles with an average diameter of 1 μm≤d2 and the H produced by the reaction 2 Gases such as S are extracted from the gas-phase outlet 6 of the gas-liquid separation tank, and the liquid-phase oil product...

Embodiment 2

[0047] Fresh hydrogen and kerosene enter the gas-liquid linkage micro-interface generator 3 through the gas-phase inlet 2 of the gas-liquid linkage micro-interface generator and the liquid phase inlet 1 of the gas-liquid linkage micro-interface generator respectively at a standard volume ratio of 0.3:1. One path enters the pneumatic microinterface generator 15 through the gas phase inlet 17 of the pneumatic microinterface generator and the liquid phase inlet 16 of the pneumatic microinterface generator respectively at a standard volume ratio of 900:1. Under the action of the gas-liquid linkage micro-interface generator 3 and the pneumatic micro-interface generator 15, hydrogen is broken into microbubbles with an average diameter of 1μm≤d2 and the H produced by the reaction 2 Gases such as S are extracted from the gas-phase outlet 6 of the gas-liquid separation tank, and the liquid-phase oil products after hydrodesulfurization are extracted from the liquid-phase outlet 7 of the ...

Embodiment 3

[0050] Fresh hydrogen and aviation kerosene enter the gas-liquid linkage micro-interface generator 3 through the gas-phase inlet 2 of the gas-liquid linkage micro-interface generator and the liquid phase inlet 1 of the gas-liquid linkage micro-interface generator respectively at a standard volume ratio of 0.28:1. The other path enters the pneumatic microinterface generator 15 through the gas phase inlet 17 of the pneumatic microinterface generator and the liquid phase inlet 16 of the pneumatic microinterface generator respectively at a standard volume ratio of 950:1. Under the action of the gas-liquid linkage micro-interface generator 3 and the pneumatic micro-interface generator 15, hydrogen is broken into microbubbles with an average diameter of 1μm≤d2 and the H produced by the reaction 2 Gases such as S are extracted from the gas-phase outlet 6 of the gas-liquid separation tank, and the liquid-phase oil products after hydrodesulfurization are extracted from the liquid-phase ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap