Composite microcapsule adsorbent for removing Cs < + > in water and preparation method thereof

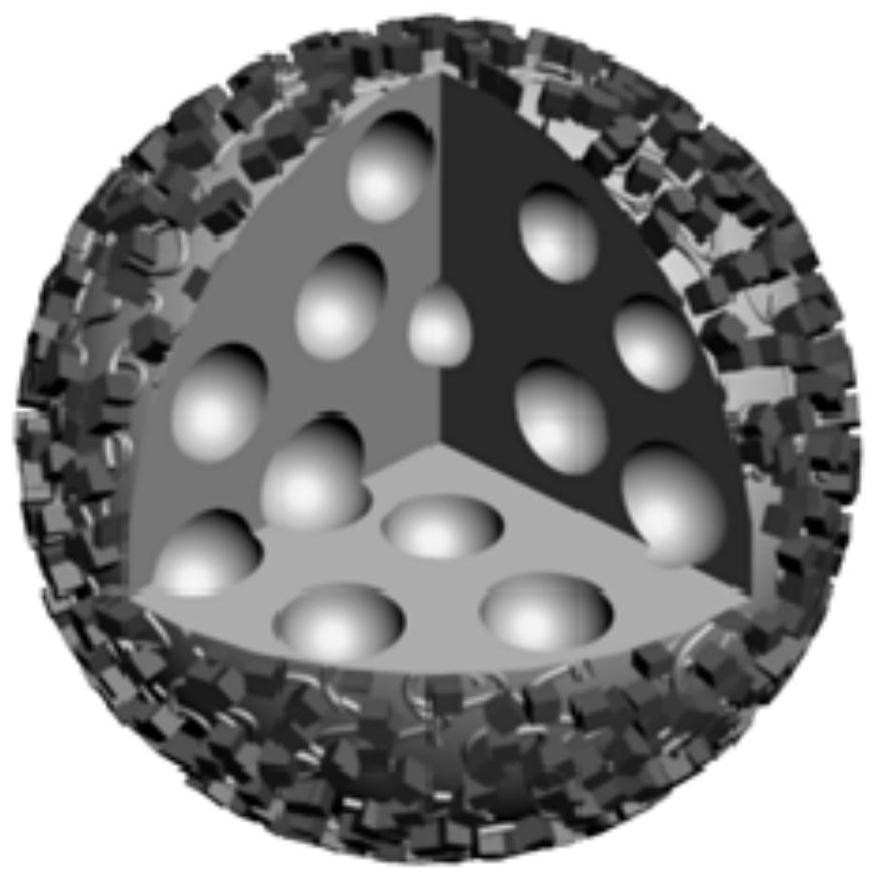

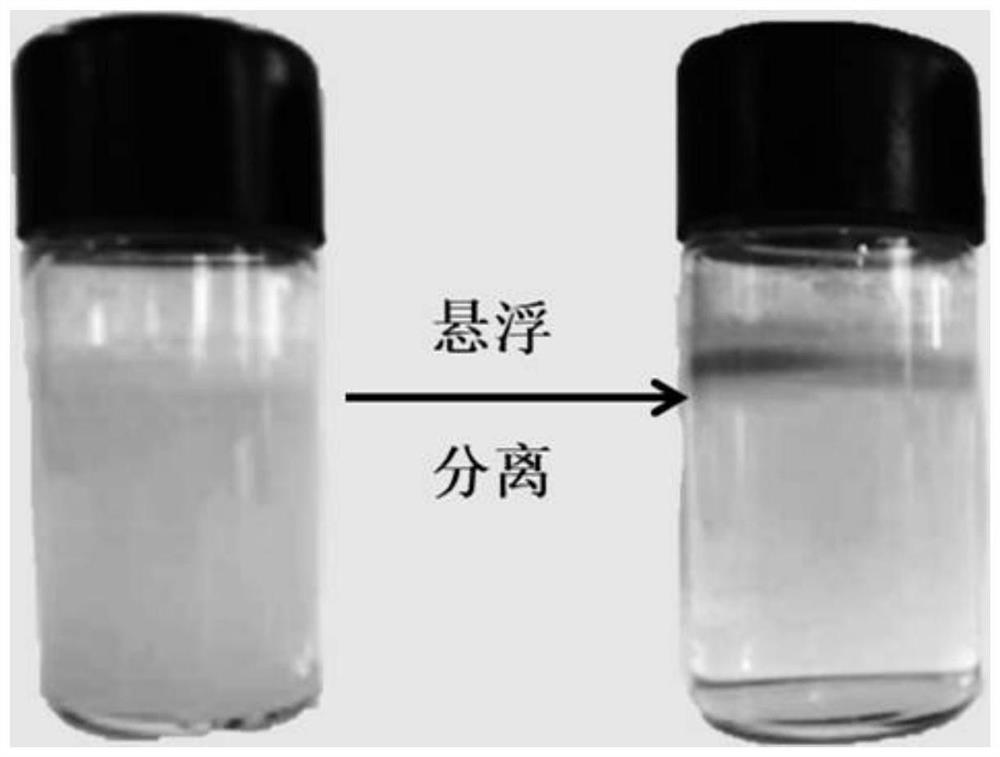

A technology of composite microcapsules and adsorbents, which is applied in the intersecting field of environment and biological materials, can solve the problems of ineffective removal of organic pollutants in water, achieve the effects of green production process, reduce energy consumption, and facilitate separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

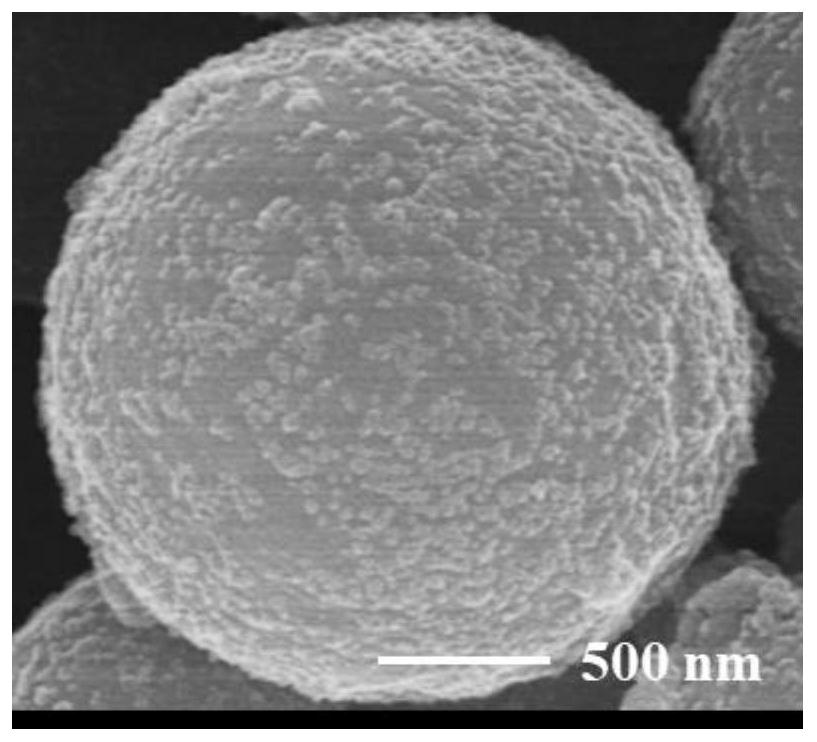

Embodiment 1

[0032] (1) Dissolve 100 mg of polylactic acid and 10 mg of camphor in 5 mL of dichloromethane, then add 0.5 mL of ammonium carbonate solution with a mass fraction of 4%, and then use the 1 / 2" probe of the ultrasonic breaker to treat for 0.5 min ; Take the above solution and gradually add it to 10 mL of polyvinyl alcohol solution with a mass fraction of 5%, and then use a high-speed dispersing homogenizer to process it at 9000 rpm for 5 min; then add 10 mL of isopropyl alcohol with a mass fraction of 2% to the solution Alcohol solution, stirred at 20°C for 120 min, washed twice with deionized water (5000 g, 5 min) repeatedly; finally, 10 mL of polyethylimide solution with a concentration of 1 mg / mL was added to the solution, and the Stir at 20 °C for 120 min, and wash twice with deionized water (5000 g, 5 min) repeatedly to obtain modified polylactic acid microcapsules.

[0033] (2) Prepare FeCl containing 0.5 mmol citric acid 3 solution (20mL, 1.0 mM), add K containing 0.5 mm...

Embodiment 2

[0036](1) Dissolve 300 mg of polylactic acid and 30 mg of camphor in 8 mL of dichloromethane, then add 0.8 mL of ammonium carbonate solution with a mass fraction of 4%, and then use the 1 / 2" probe of the ultrasonic breaker to treat for 0.5 min ; Take the above solution and gradually add it to 30 mL of polyvinyl alcohol solution with a mass fraction of 5%, and then use a high-speed dispersing homogenizer to process it at 9000 rpm for 5 min; then add 30 mL of isopropyl alcohol with a mass fraction of 2% to the solution Alcohol solution, stirred at 25°C for 120 min, washed with deionized water repeatedly (5000 g, 5 min) for 2 to 3 times; finally, 10 to 50 mL of polyacetylene at a concentration of 1 mg / mL was added to the solution The amine solution was stirred at 25 °C for 120 min, and washed with deionized water repeatedly (5000 g, 5 min) for 2 to 3 times to obtain modified polylactic acid microcapsules.

[0037] (2) Prepare FeCl containing 0.5 mmol citric acid 3 solution (30 m...

Embodiment 3

[0040] (1) Dissolve 500mg of polylactic acid and 150mg of camphor in 10mL of dichloromethane, then add 1.0mL of ammonium carbonate solution with a mass fraction of 4%, and then use the 1 / 2" probe of the ultrasonic breaker to treat for 0.5 min; take the above The solution was gradually added to 50 mL of polyvinyl alcohol solution with a mass fraction of 5%, and then treated with a high-speed dispersing homogenizer at 9000 rpm for 5 min; then 50 mL of isopropanol solution with a mass fraction of 2% was added to the solution, Stir at 30 °C for 120 min, wash with deionized water repeatedly (5000 g, 5 min) for 3 times; finally add 50 mL of polyethylimide solution with a concentration of 1 mg / mL to the solution, Stir for 120 min, and wash with deionized water repeatedly (5000 g, 5 min) for 3 times to obtain modified polylactic acid microcapsules.

[0041] (2) Prepare FeCl containing 0.5 mmol citric acid 3 solution (50 mL, 1.0 mM), add K containing 0.5 mmol citric 4 [Fe(CN) 6 ] so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com