Carbon ribbon capable of being used for making books for the blind and manufacturing method thereof

A technology for books and carbon ribbons, applied in the direction of ink ribbons, film/sheet adhesives, adhesive types, etc., to achieve low requirements, reduce production costs, and print quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

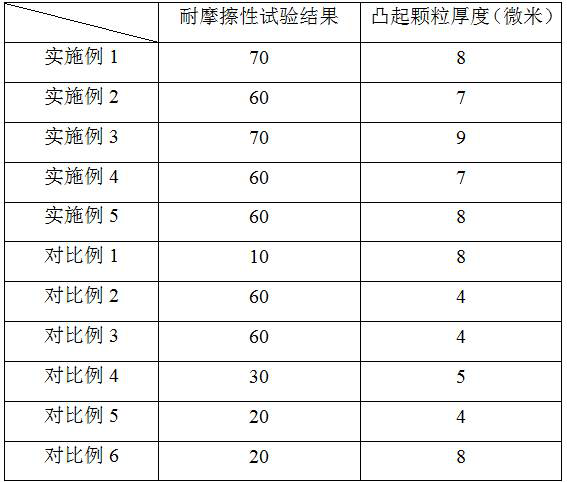

Examples

Embodiment 1

[0021] On the base material PET film (thickness 4.5 μm, manufactured by Henan Zhuoli Membrane Material Co., Ltd.) according to the conventional method in this field, each layer is coated according to the following steps, and finally the product can be used for the production of Braille books. ribbon.

[0022] 1) Foaming microcapsules

[0023] Add 20 parts by weight of TPU resin (PEARLSTICK 5715 manufactured by Lubrizol Company) into 40 parts by weight of methyl ethyl ketone, heat and stir for 30 minutes to completely dissolve, then add sodium bicarbonate (Shandong Haihua Group Co., Ltd. , food grade) 10 parts by weight, then disperse with a high-speed shear emulsifier with a rotating speed of 900rpm for 8-10h, add a coagulation solvent (30 parts by weight of toluene) to continue to disperse and mix to produce flocculation, let stand for 24h, discard the supernatant, Then rinse with a mixed solvent of water and ethanol at a volume ratio of 1:1 to obtain microcapsule slurry, pu...

Embodiment 2

[0046] The raw material composition and proportioning of foamed microcapsules are as follows, and others are the same as in Example 1;

[0047] 20 parts by weight of TPU resin (PEARLSTICK 5715 manufactured by Lubrizol);

[0048] Sodium bicarbonate (Shandong Haihua Group Co., Ltd., food grade) 6 parts by weight;

[0049] Butanone 44 parts by weight;

[0050] 30 parts by weight of toluene.

Embodiment 3

[0052] The raw material composition and proportioning of foamed microcapsules are as follows, and others are the same as in Example 1;

[0053] 20 parts by weight of TPU resin (PEARLSTICK 5715 manufactured by Lubrizol);

[0054] Sodium bicarbonate (Shandong Haihua Group Co., Ltd., food grade) 12 parts by weight;

[0055] Butanone 38 parts by weight;

[0056] 30 parts by weight of toluene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com