Novel airtight protection cover device of electroslag furnace

An electroslag furnace and protective cover technology, applied in the field of metallurgical equipment, can solve the problems of increasing the smelting space of protective gas supply, increasing production costs and safety risks, reducing the quality and yield of steel ingots, etc., so as to reduce production costs and Safety risks, preventing outside air from entering, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

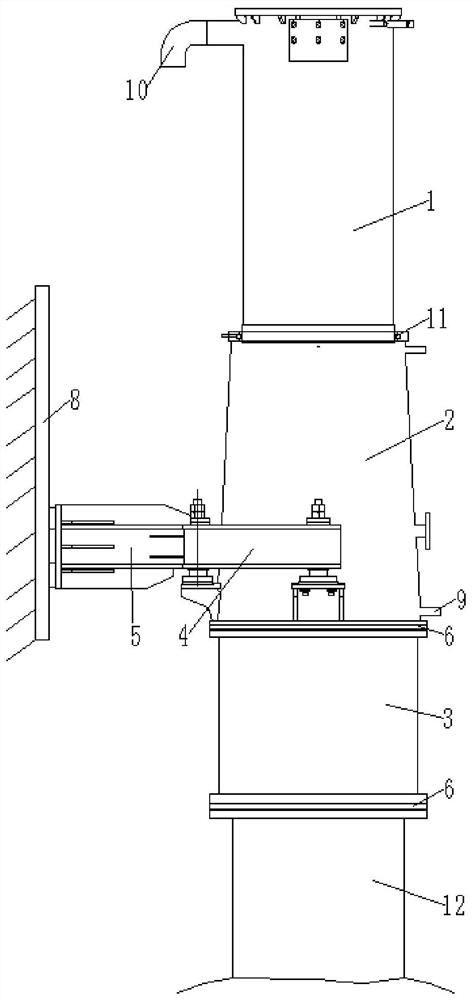

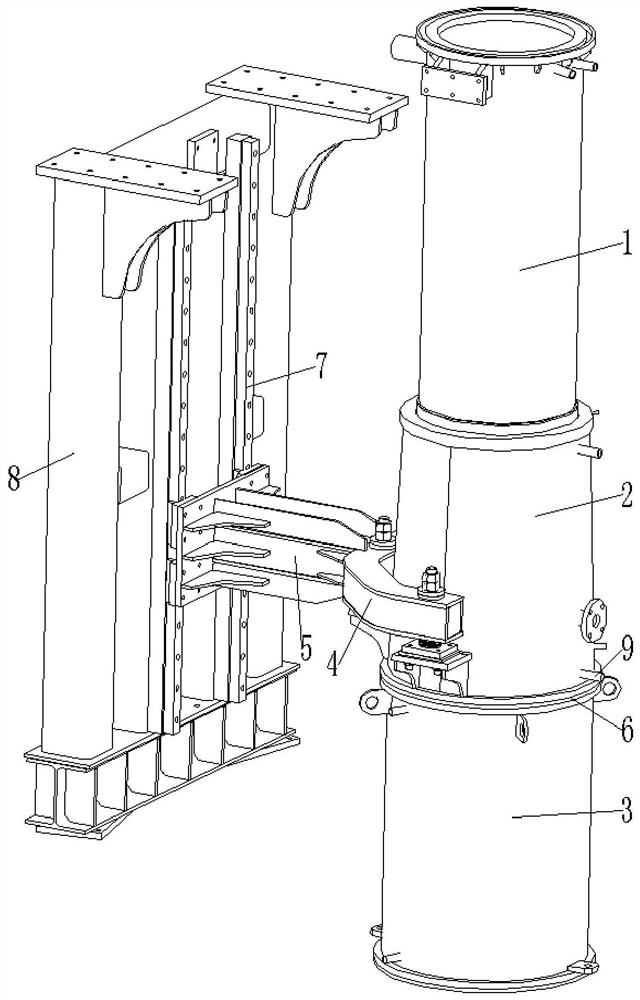

[0019] First of all, the original design intention of the present invention is explained. Electroslag furnace is an indispensable production equipment in special steel mills. At present, coaxial electroslag furnaces at home and abroad have no protective cover device, and some equipment have protective cover device. Most of the protective cover devices are two-door or four-door protective cover devices, and the overall airtight effect is not so good, so that the quality of the smelted steel ingots is not good, and the yield rate is also greatly reduced. In addition, during the smelting process, many The enterprise reduces the oxygen content in the smelting space by increasing the gas supply of argon gas. This method increases the production cost and also increases the safety risk. Therefore, the present invention designs a new airtight protective cover device for the electroslag furnace.

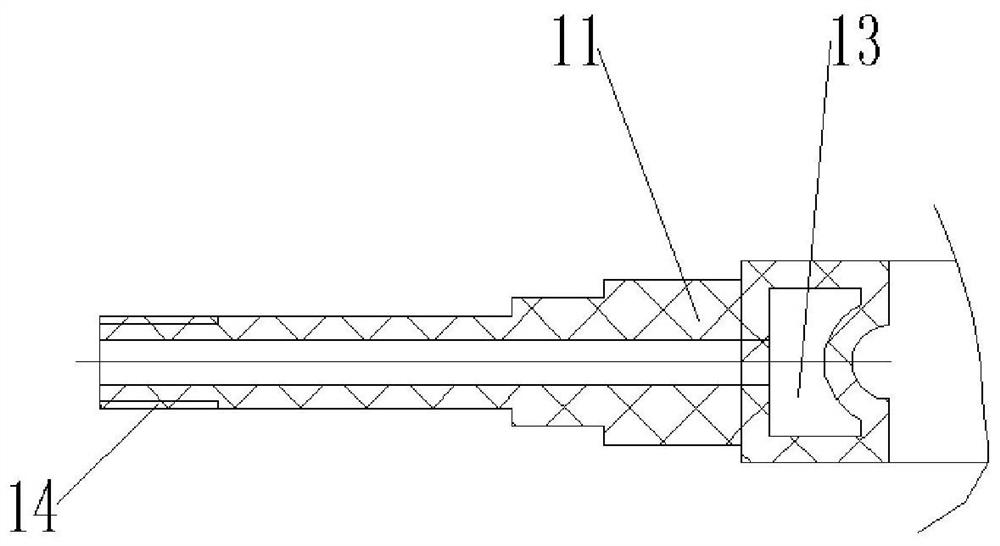

[0020] The present invention is specifically described below in conjunction with accompany...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com