A kind of separation method of crystal and crystal support

A separation method and crystal technology, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve problems such as damage, easy deviation of cutting direction, loss, etc., to reduce risks, simple separation method, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

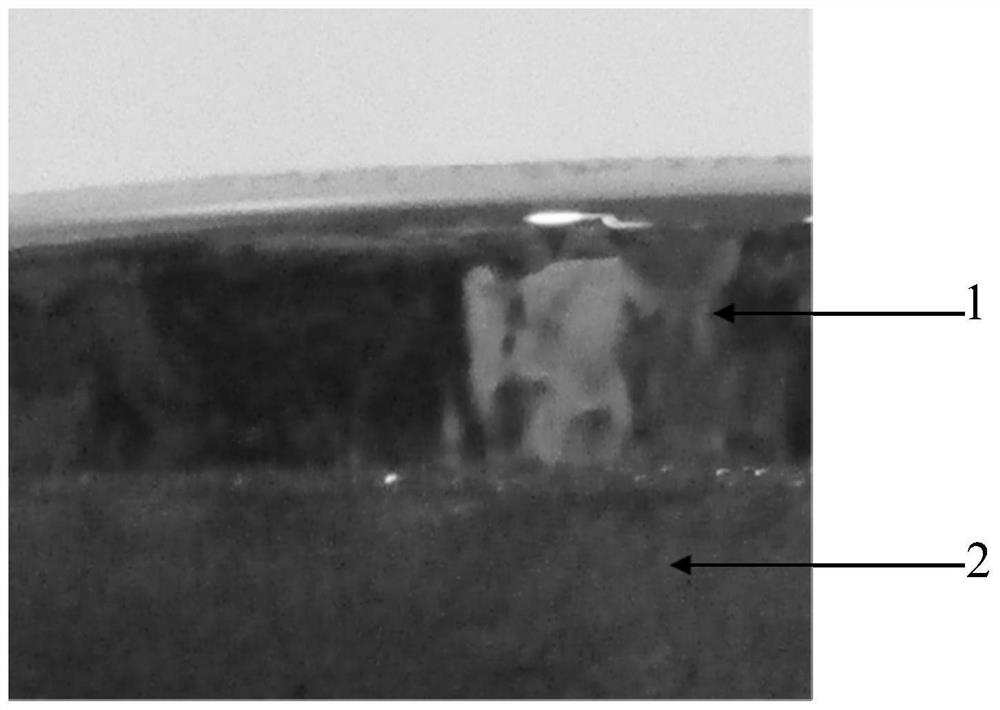

[0031] Embodiment 1 provides a method for separating the grown silicon carbide crystal 1 (40 mm thick) from the graphite crystal holder 2 fixed at the bottom thereof, comprising the following steps:

[0032] 1. Put the silicon carbide crystal 1 to be separated and the graphite crystal holder 2 fixed with it into the tube furnace;

[0033] 2. Open the air inlet on the tube furnace and let in air;

[0034] 3. Open the exhaust port on the tube furnace to maintain air circulation;

[0035] 4. Set the tube furnace temperature to 900°C and the heating rate to 10°C / min;

[0036] 5. Set the carbon oxidation time to 12h and keep the temperature unchanged;

[0037] 6. After the carbon oxidation reaction is carried out for 12 hours, set the cooling rate to 10°C / min;

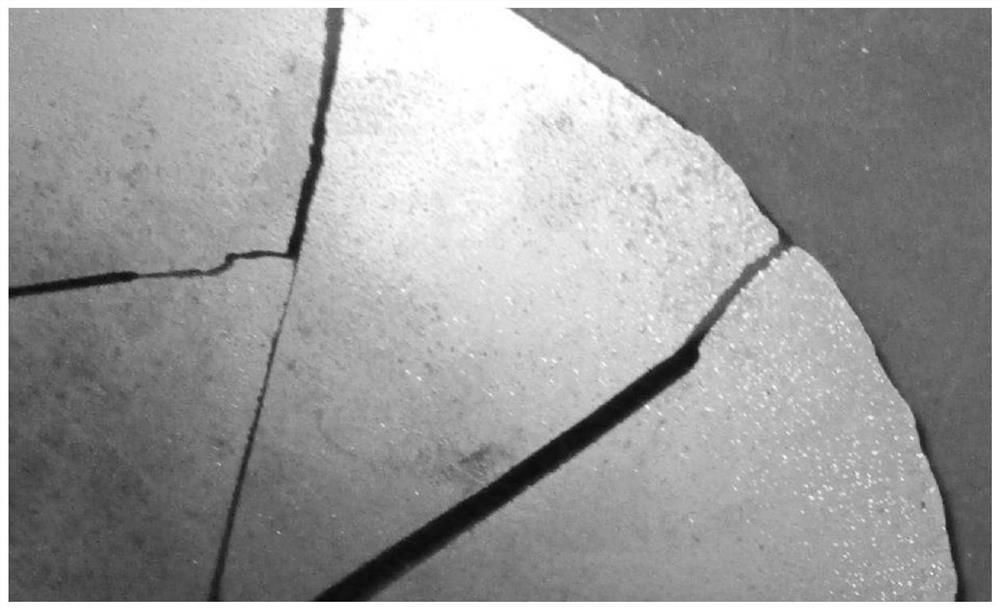

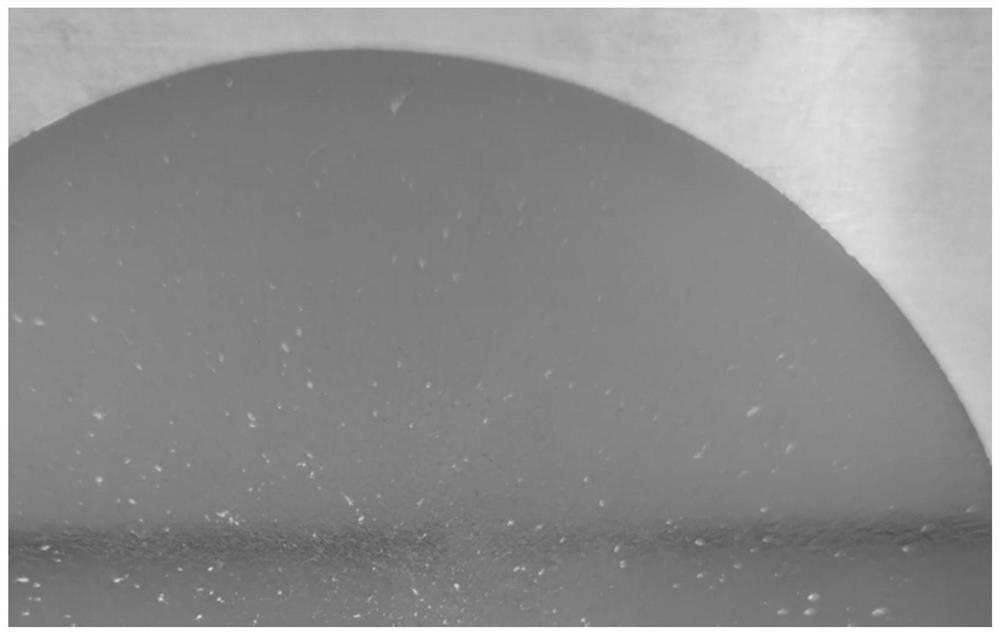

[0038] 7. When the temperature in the tube furnace is lowered to below 50°C, open the tube furnace. At this time, the graphite has been completely oxidized to carbon dioxide and discharged out of the tube furnace, leavin...

Embodiment 2

[0041] Embodiment 2 provides a method for separating the grown aluminum nitride crystal 1 (10 mm thick) from the graphite crystal holder 2 fixed at the bottom thereof, comprising the following steps:

[0042] 1. Put the aluminum nitride crystal 1 to be separated and the graphite crystal holder 2 fixed with it into a muffle furnace (model: FR-1236);

[0043] 2. Open the air inlet on the muffle furnace and let in air;

[0044] 3. Open the exhaust port on the muffle furnace to maintain air circulation;

[0045] 4. Set the muffle furnace temperature to 800°C and the heating rate to 1°C / min;

[0046] 5. Set the carbon oxidation time to 6h and keep the temperature unchanged;

[0047] 6. After the carbon oxidation reaction is carried out for 6 hours, set the cooling rate to 1°C / min;

[0048] 7. When the temperature in the muffle furnace drops below 50°C, turn on the muffle furnace. At this time, the graphite has been completely oxidized to carbon dioxide and discharged out of the ...

Embodiment 3

[0050] Embodiment 3 provides a method for separating the grown gallium nitride crystal 1 (10 mm thick) from the graphite crystal holder 2 fixed at the bottom thereof, comprising the following steps:

[0051] 1. Put the gallium nitride crystal 1 to be separated and the graphite crystal holder 2 fixed with it into a muffle furnace (model: FR-1236);

[0052] 2. Open the air inlet on the muffle furnace and let in air;

[0053] 3. Open the exhaust port on the muffle furnace to maintain air circulation;

[0054] 4. Set the muffle furnace temperature to 1000°C and the heating rate to 20°C / min;

[0055] 5. Set the carbon oxidation time to 12 hours and keep the temperature unchanged;

[0056] 6. After the carbon oxidation reaction is carried out for 12 hours, set the cooling rate to 20°C / min;

[0057] 7. When the temperature in the muffle furnace drops below 50°C, turn on the muffle furnace. At this time, the graphite has been completely oxidized to carbon dioxide and discharged out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com