fe 3 o 4 ‑cooh magnetic nanomaterial modified open-tubular column and its preparation method and application

A magnetic nanometer and open-column technology is applied in the field of chromatography to achieve the effects of simple preparation method conditions, improved separation effect and good separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

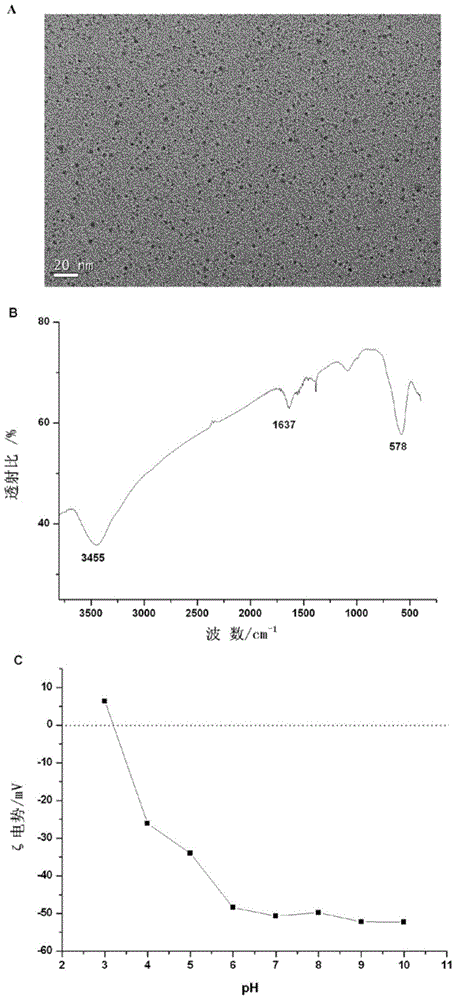

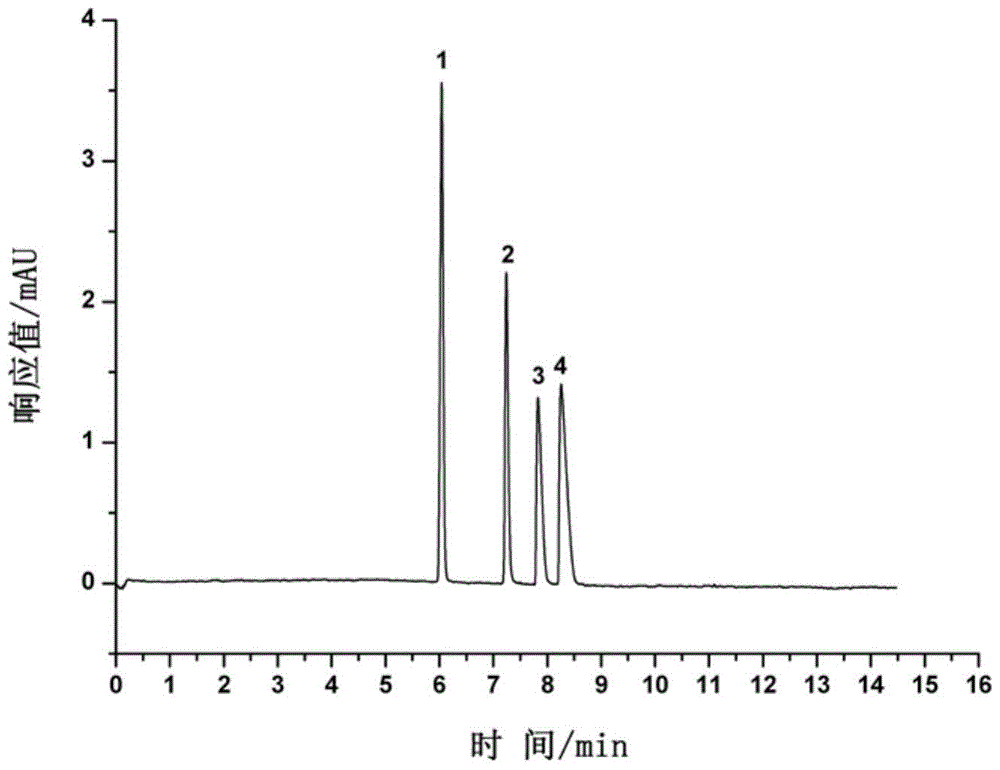

[0045] Example 1: PDDA@Fe 3 O 4 -COOH MNPs open-tube column preparation

[0046] (1)Fe 3 O 4 -COOH MNPs preparation: add 6mM FeCl 3 ·6H 2 O was added to 40mL of diethylene glycol for ultrasonic assisted dissolution, then 55mM anhydrous sodium acetate and 48mM sodium acrylate were added, and stirred in a constant temperature water bath at 70℃ at 500r / min for 1h to form a homogeneous solution. Pour the solution into the special Put into an oven, heat up to 200℃, react for 10h, and cool to room temperature. Separate the product under an external magnetic field and wash it with ethanol and deionized water three times in sequence. Dry at 50℃ to obtain dispersion Uniform Fe 3 O 4 -COOH MNPs magnetic particles.

[0047] (2) Capillary pretreatment: 1mol / L HCl was flushed sequentially at a flow rate of 10μL / min for 1h to remove organic substances on the inner surface of the capillary, deionized water for 1h to remove excess HCl, 1mol / L NaOH for 1h to etch the inner surface of the capillary ...

Embodiment 2

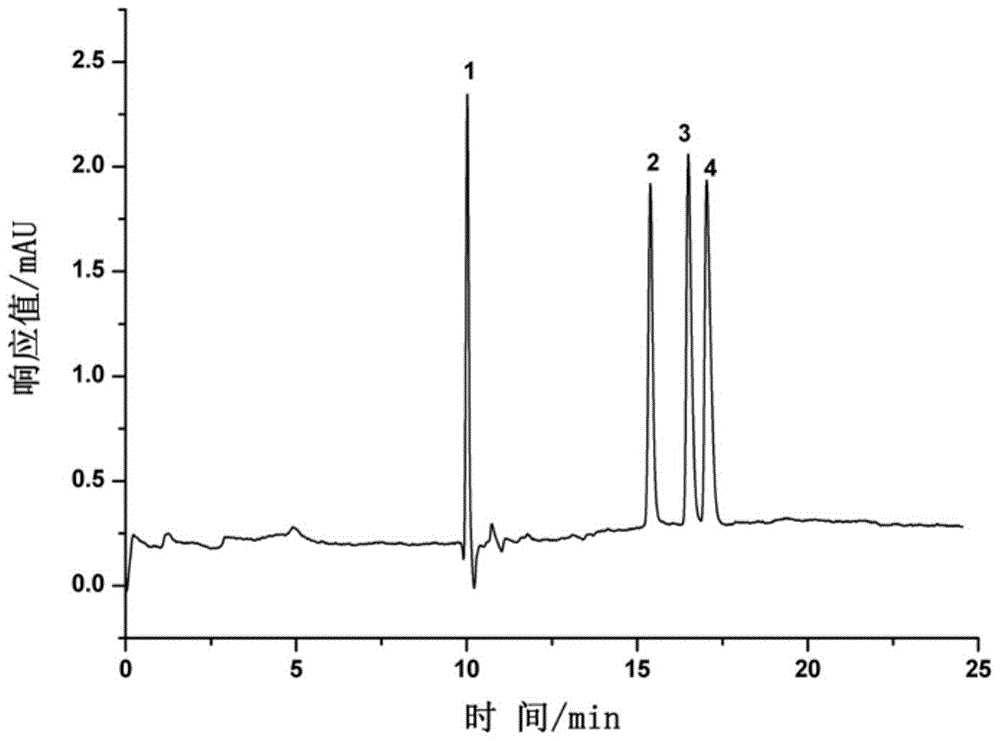

[0051] Example 2: PDDA@Fe 3 O 4 -COOH MNPs open-tube column preparation

[0052] (1)Fe 3 O 4 -COOH MNPs preparation: add 8mM FeCl 3 ·6H 2 O was added to 40 mL of diethylene glycol for ultrasonic assisted dissolution, then 50 mM anhydrous sodium acetate and 40 mM sodium acrylate were added, and stirred in a constant temperature water bath at 50°C at 300 r / min for 1 hour to form a homogeneous solution. Pour the solution into the special Put into an oven, heat up to 180℃, react for 15h, and cool to room temperature. Separate the product under an external magnetic field and wash it with ethanol and deionized water three times in sequence. Dry at 40℃ to obtain dispersion Uniform Fe 3 O 4 -COOH MNPs magnetic particles.

[0053] (2) Capillary pretreatment: 1.5mol / L HCl was flushed sequentially at a flow rate of 15μL / min for 1.5h to remove organic substances on the inner surface of the capillary, deionized water for 1.5h to remove excess HCl, 1.5mol / L NaOH for 1.5h to etch the capillary T...

Embodiment 3

[0056] Example 3: PDDA@Fe 3 O 4 -COOH MNPs open-tube column preparation

[0057] (1)Fe 3 O 4 -COOH MNPs preparation: 10mM FeCl 3 ·6H 2 O was added to 40 mL of diethylene glycol for ultrasonic assisted dissolution, then 60 mM anhydrous sodium acetate and 50 mM sodium acrylate were added, and stirred in a constant temperature water bath at 60 ℃ at 400 r / min for 1 h to form a homogeneous solution. Pour the solution into the special Put into an oven, heat up to 190℃, react for 20h, cool to room temperature, separate the product under an external magnetic field and wash it with ethanol and deionized water three times in sequence, and dry at 50℃ to obtain dispersion Uniform Fe 3 O 4 -COOH MNPs magnetic particles.

[0058] (2) Capillary pretreatment: 2mol / L HCl was sequentially flushed at a flow rate of 20μL / min for 2h to remove organic substances on the inner surface of the capillary, deionized water for 2h to remove excess HCl, 2mol / L NaOH for 2h to etch the inner surface of the capilla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com