Gas cladding low-loss polarization optical fiber

A polarized optical fiber, low loss technology, applied in polarized optical fiber, clad optical fiber, multi-layer core/clad optical fiber, etc., can solve the difficulty of splicing, can not withstand high temperature baking and cosmic ray radiation, and the temperature performance of optical fiber is not good Good and other problems, to achieve the effect of low absorption loss, low material scattering loss, and reduce consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

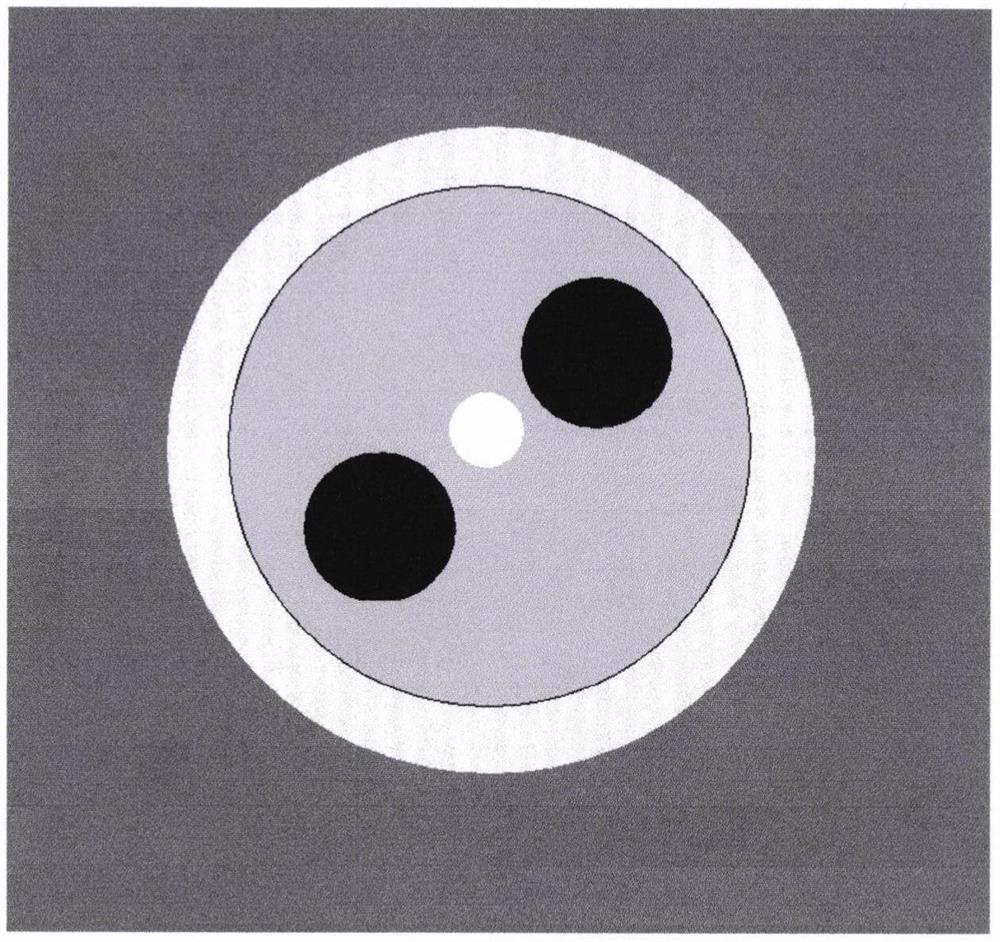

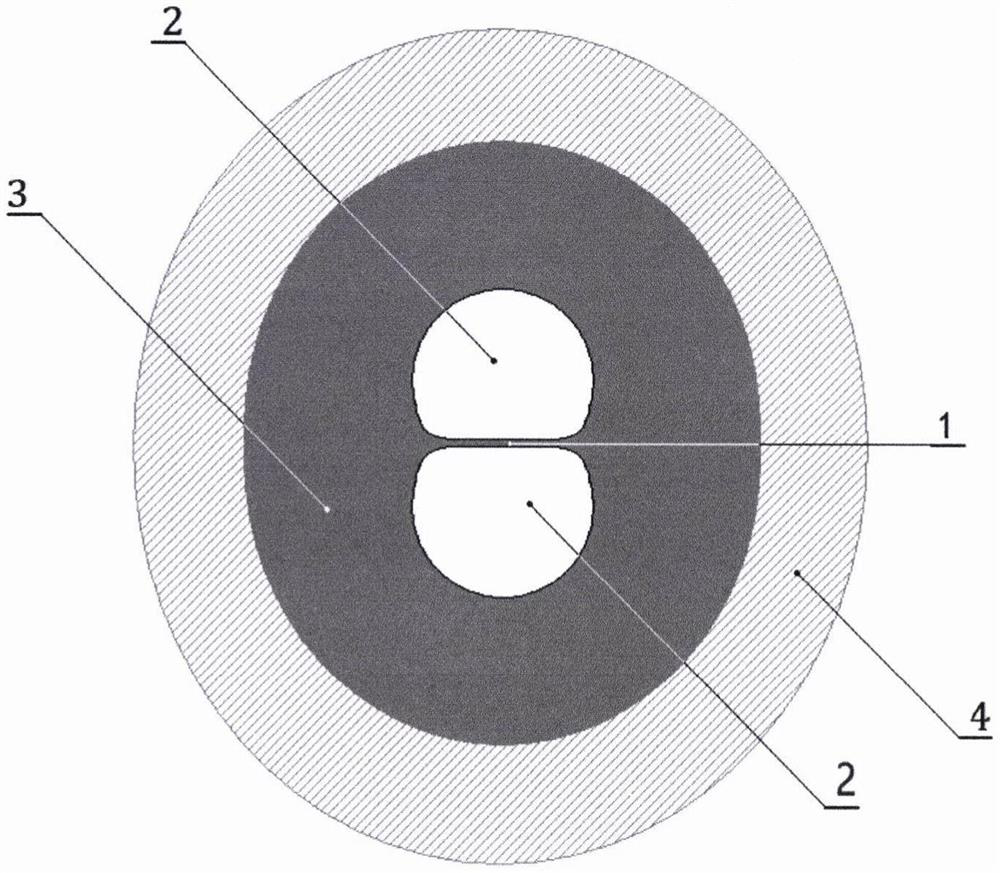

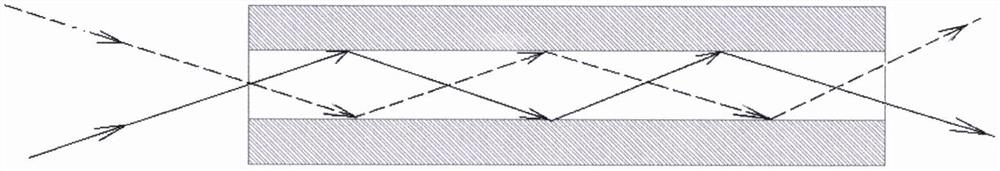

Image

Examples

Embodiment Construction

[0052] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0053] The detection fiber length is 22.8Km;

[0054] Protective Coating Material: Polyimide Optical Fiber Coating

[0055]

[0056] Temperature test: total length 22.8km

[0057] Low temperature: -85 degrees (Celsius) for 72 hours, the change of instrument reading at the output end is ±0.01dB

[0058] High temperature: +92 degrees (Celsius) 72 hours output instrument reading change +0.003dB

[0059] A method for preparing a gas-clad low-loss polarization optical fiber:

[0060] A gas-clad low-loss polarization fiber is produced in 8 steps:

[0061] Step 1. Preparation of raw materials: select a commercially available solid outer cladding ultra-high purity quartz glass sleeve with a length of 1200 mm and an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com