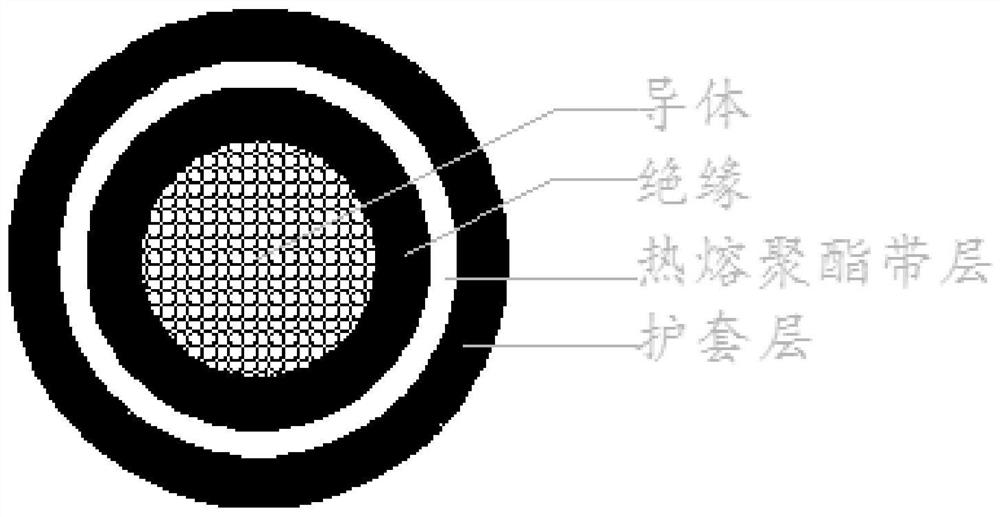

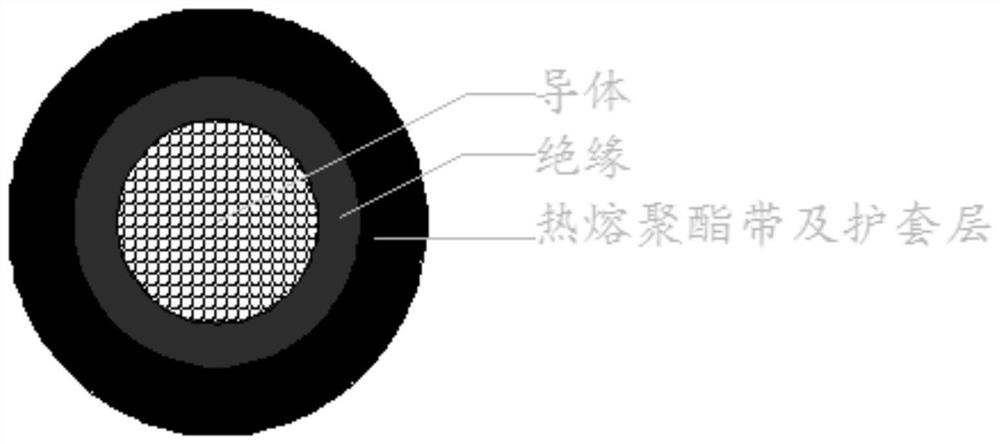

Flexible cable with sheath and preparation method thereof

A flexible cable and sheath type technology, used in cable/conductor manufacturing, insulated cables, cables, etc., can solve problems such as cable breakdown, water tree branches in the insulation layer, and cable aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The present invention has no special limitation on the preparation method of the double-sided hot-melt polyester tape, and any method known to those skilled in the art will suffice.

[0061] In some specific embodiments of the present invention, the number of layers of the double-sided hot-melt polyester tape is two.

[0062] In the present invention, the tensile force of the hot-melt polyester tape should be greater than 100N, and the elongation at break should be greater than 60%.

[0063] The present invention also provides a method for preparing a sheathed flexible cable, comprising the following steps:

[0064] The insulated core is wrapped or dragged with a hot-melt polyester tape, and then the sheath layer is extruded, and after cooling, a sheathed flexible cable is obtained.

[0065] First, the insulated wire core is wrapped or wrapped with a hot-melt polyester tape, and the covering rate of the wrapped or dragged hot-melt polyester tape is 0% to 10%.

[0066]...

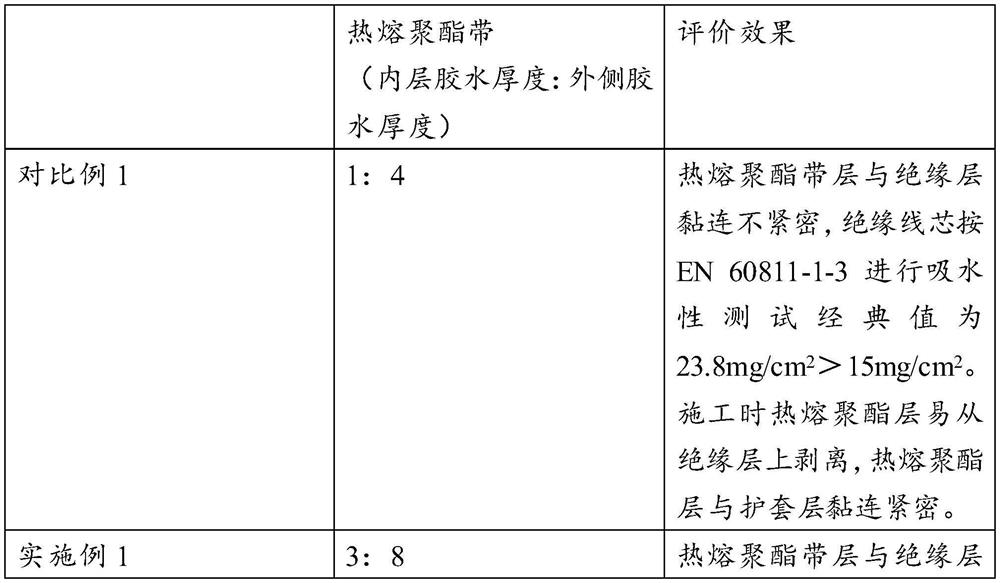

Embodiment 1

[0085] The structure of the double-sided hot-melt polyester tape includes a PET substrate film layer with a thickness of 0.017mm, an inner hot-melt adhesive layer with a thickness of 0.003mm in contact with the insulating layer and a thickness of 0.008mm in contact with the sheath layer. mm outer hot melt adhesive layer.

[0086] The inner hot melt adhesive layer is prepared from the following raw materials in parts by weight:

[0087] 98 parts by weight of polyurethane, 0.5 parts by weight of nano-calcium carbonate reinforcing agent, 0.2 parts by weight of diphenylamine, 0.2 parts by weight of polycarbodiimide, 0.05 parts by weight of dibutyl hydroxytoluene, and acetone of 0.05 parts by weight;

[0088] The outer hot melt adhesive layer is prepared from the following raw materials in parts by mass:

[0089] 90 parts by weight of polyurethane, 2 parts by weight of polyolefin, 1 part by weight of dicumyl peroxide, 1 part by weight of nanometer calcium carbonate reinforcing age...

Embodiment 2

[0092] The structure of the double-sided hot-melt polyester tape includes a PET base film layer with a thickness of 0.017mm, an inner hot-melt adhesive layer with a thickness of 0.003mm in contact with the insulating layer and a thickness of 0.008mm in contact with the sheath layer. mm outer hot melt adhesive layer.

[0093] The inner hot melt adhesive layer is prepared from the following raw materials in parts by weight:

[0094] 99 parts by weight of polyurethane, 0.9 parts by weight of nano-calcium carbonate reinforcing agent, 0.5 parts by weight of diphenylamine, 0.5 parts by weight of polycarbodiimide, 0.1 parts by weight of dibutyl hydroxytoluene, and 0.1 parts by weight of acetone;

[0095] The outer hot melt adhesive layer is prepared from the following raw materials in parts by mass:

[0096] 95 parts by weight of polyurethane, 4 parts by weight of polyolefin, 2 parts by weight of dicumyl peroxide, 1.9 parts by weight of nano-calcium carbonate reinforcing agent, 0.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com