Antipole membrane electrode for fuel cell and preparation method of antipole membrane electrode

A fuel cell and membrane electrode technology, applied in the field of electrochemistry, can solve the problem of uneven distribution of anti-counteractive active substances, and achieve the effect of improving uniformity and achieving uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method for an anti-counterpolar membrane electrode for a fuel cell, comprising the steps of:

[0034] (1) Take 0.01mol of ammonium chloroiridate particles and add 0.02mol of lithium carbonate powder, mix evenly, place in the air atmosphere in the muffle furnace, and sinter at 750°C for 3 hours, take 0.1g of the powder obtained after sintering, and add 1mL of it in turn Pure water, 3mL ethanol and 40 μ L of Nafion emulsion with a mass fraction of 5% were uniformly dispersed and coated on the surface of the graphite sheet, and the modified electrode (graphite sheet coated with iridium active material) was inserted into a sulfuric acid solution with a concentration of 0.5M. The counter electrode is a platinum sheet, and a -1V potential is applied to polarize for 0.5h at room temperature to obtain the treated sulfuric acid solution;

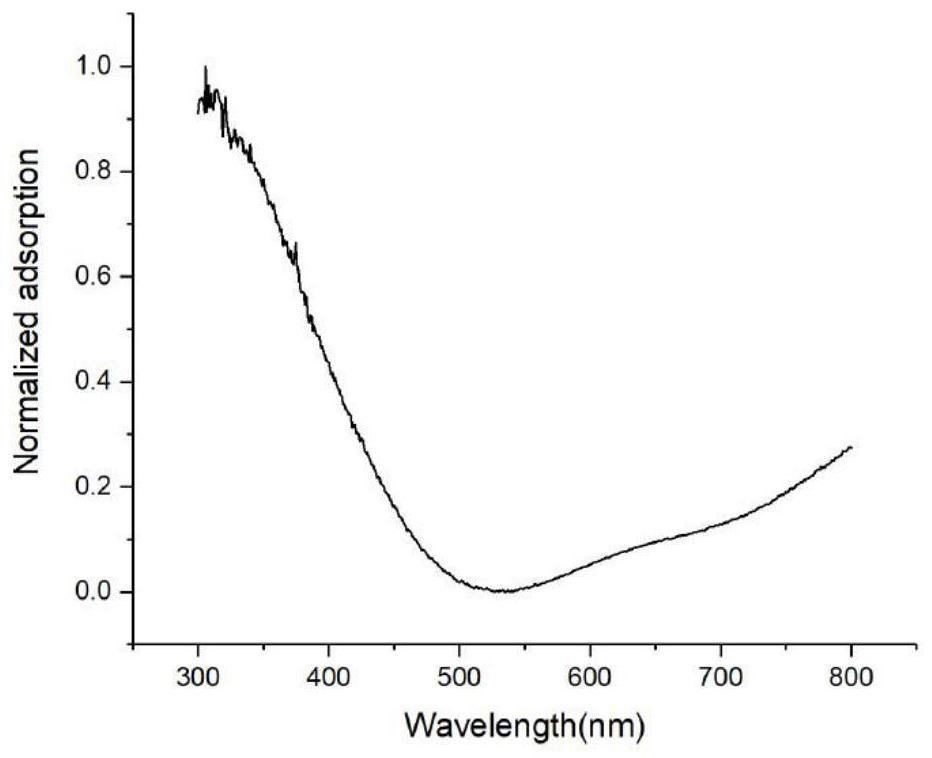

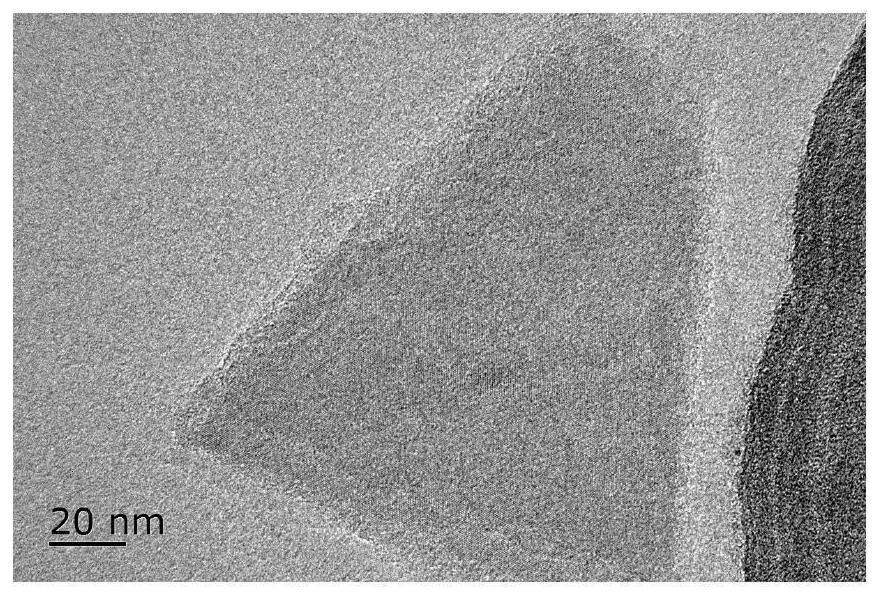

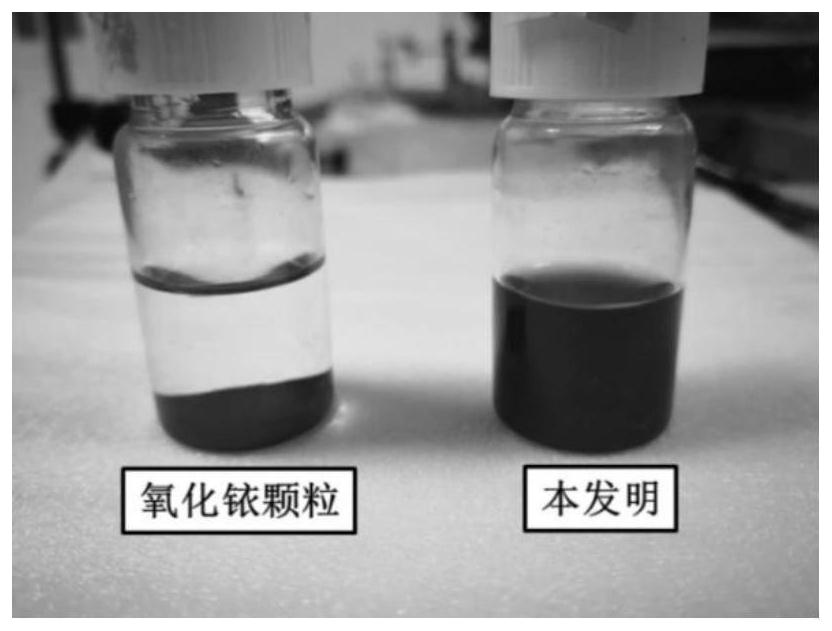

[0035] (2) Subsequently, the treated sulfuric acid solution was centrifuged at a speed of 10000r / min for 0.5h to obtain an irid...

Embodiment 2

[0043] Same as Example 1, the difference is:

[0044] Step (1) The molar ratio of ammonium chloroiridate to lithium carbonate is 1:1, the sintering conditions are sintering temperature 1000°C for 15 hours, the cathode polarization potential is -0.5V for 1h, and then the iridium active material concentration is 50mg / mL; In the step (3), the content of the iridium active material in the membrane electrode is 15%.

[0045] All the other steps and test method are completely consistent with Example 1. The anti-reversal test shows that the unit power of the battery of the membrane electrode obtained in this embodiment only drops by 13mW after the electrode is reversed.

Embodiment 3

[0047] Same as Example 1, the difference is:

[0048] Step (1) The molar ratio of ammonium chloroiridate to lithium carbonate is 1:3, the sintering conditions are sintering temperature 900°C for 12h, the sulfuric acid electrolyte concentration is 0.1M, and the cathode polarization potential is 0V for 2h, step (2) Adopt the mixed solution of ethanol and water in, wherein the volume ratio of water and ethanol is 1:1, the suspension concentration of preparation iridium is 1mg / mL; In the step (3), the mass fraction of iridium active material in membrane electrode is 1% .

[0049] All the other steps and test method are completely consistent with Example 1. The anti-reversal test showed that the unit power of the battery of the membrane electrode obtained in this example decreased by 77mW after the electrode was reversed, and the performance of the electrode was still better than that of Comparative Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com