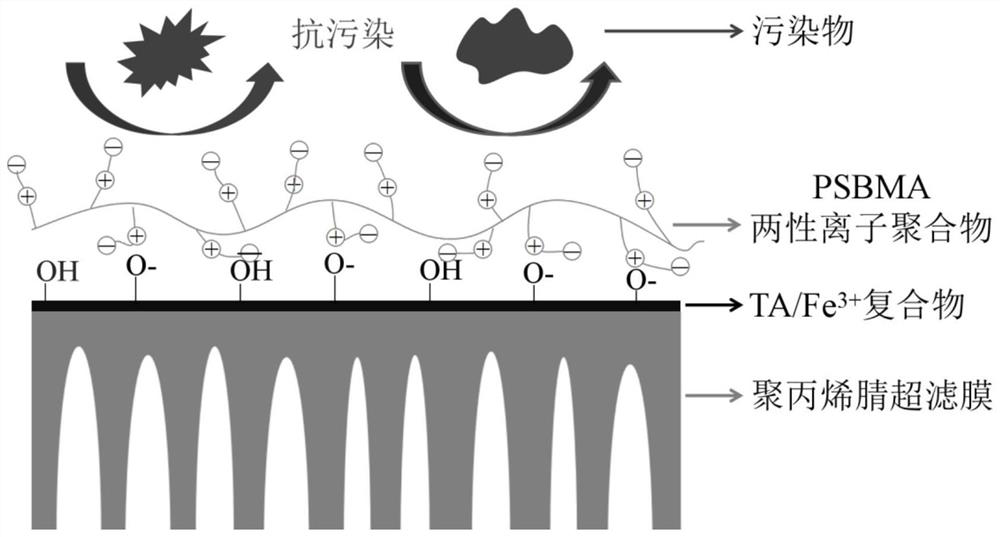

Anti-pollution nanofiltration membrane based on tannic acid multi-layer assembly as well as preparation and application

A technology of layer-by-layer assembly and tannic acid, which is applied in the field of preparation of anti-pollution nanofiltration membranes, can solve the problems of single function and long time consumption, and achieve the effects of inhibiting deposition, ensuring uniformity and good retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

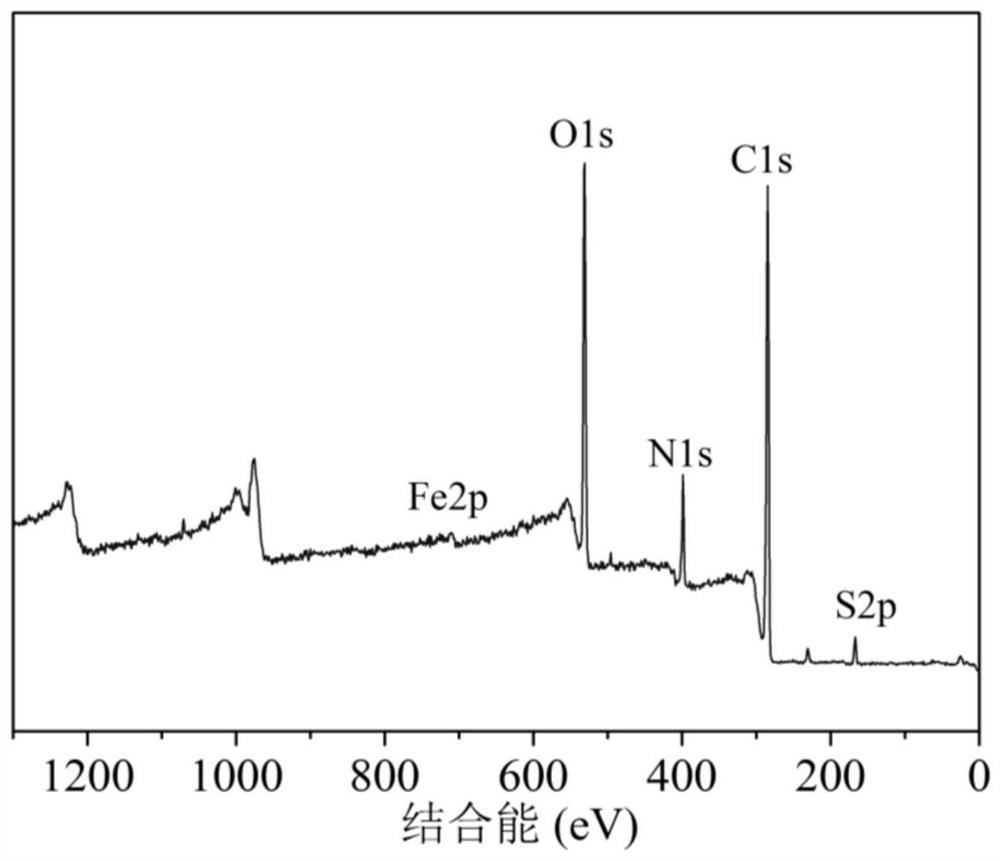

Method used

Image

Examples

Embodiment 1

[0039] A preparation of anti-pollution nanofiltration membrane, comprising the following steps:

[0040] Step 1, make the PSBMA solution that mass volume concentration is 60mg / L:

[0041] Step 1-1, synthesis of PSBMA zwitterionic polymer: 30 mg of sodium metabisulfite and 80 mg of ammonium persulfate were dissolved in a mixed solution of 5 mL of water and ethanol, and 1.8861 g of methacryloyl ethyl sulfobetaine was added thereto. After reacting at 38°C for 1 hour, place it in a refrigerator at -20°C to terminate the reaction; dialyze and freeze-dry the product to obtain PSBMA zwitterionic polymer, which is ready for use;

[0042] Step 1-2, prepare a phosphate buffer solution with a concentration of 10mmol / L and a pH value of 5, and set aside;

[0043] Step 1-3, dissolving the PSBMA zwitterionic polymer prepared in step 1-1 in the phosphate buffer prepared in step 1-2 to prepare a PSBMA solution with a mass volume concentration of 60 mg / L for future use.

[0044] Step 2, prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

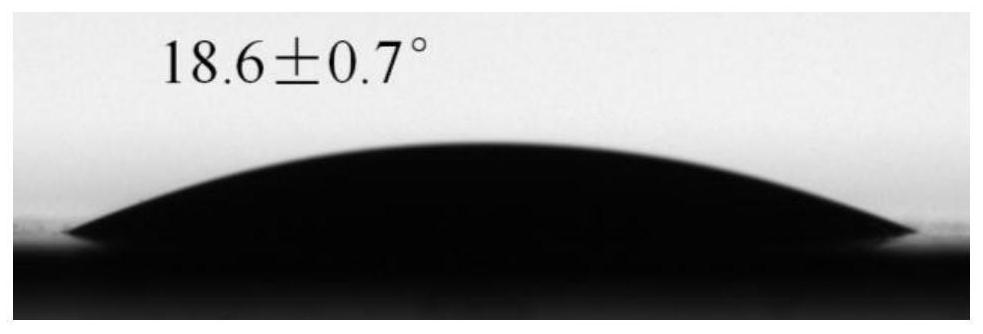

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com