A kind of polyester waste recycling method

A waste recycling and polyester technology, which is applied in plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of affecting the recycling effect of polyester waste, failing to clean grease and dust, etc., achieving good washing effect and improving suppleness Sexuality and excellent product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

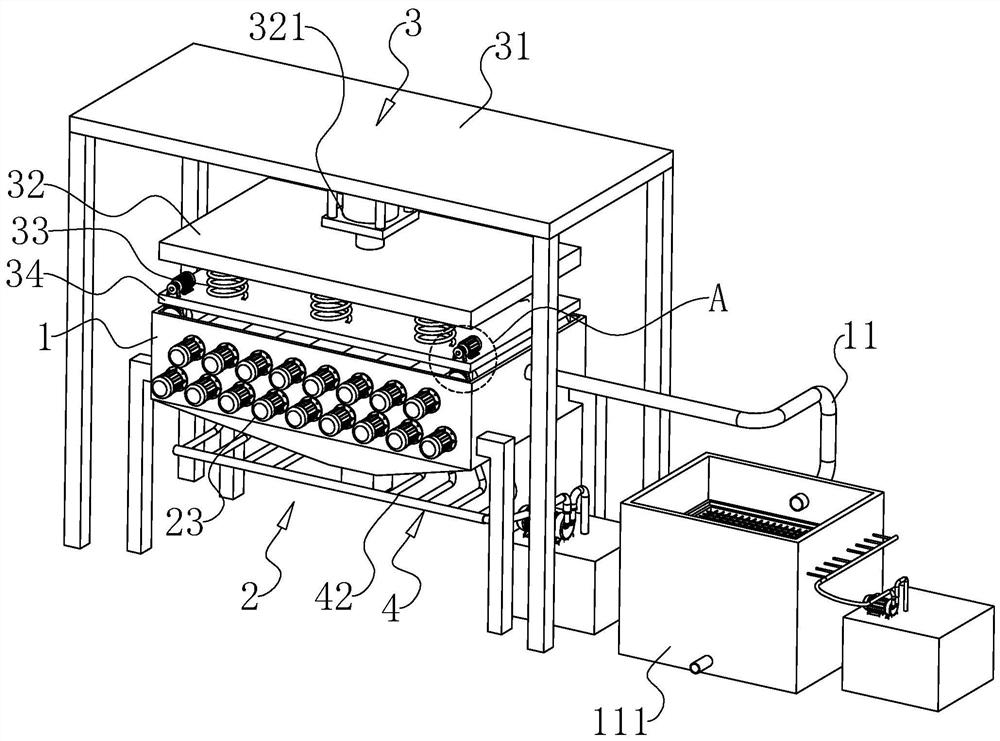

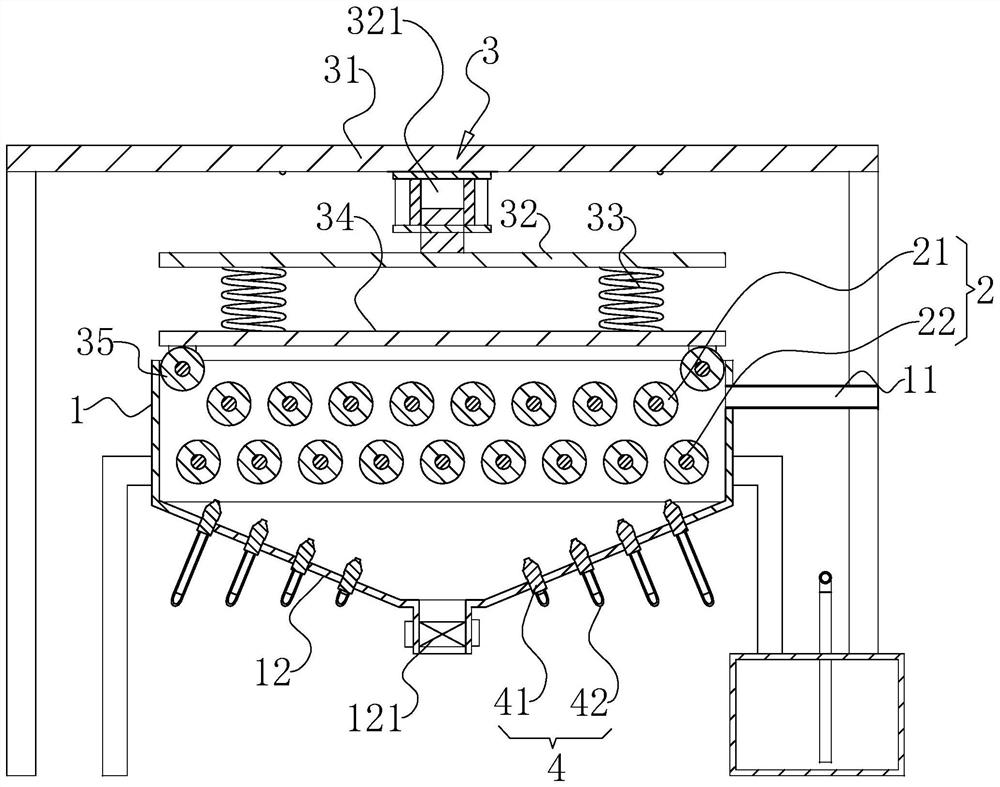

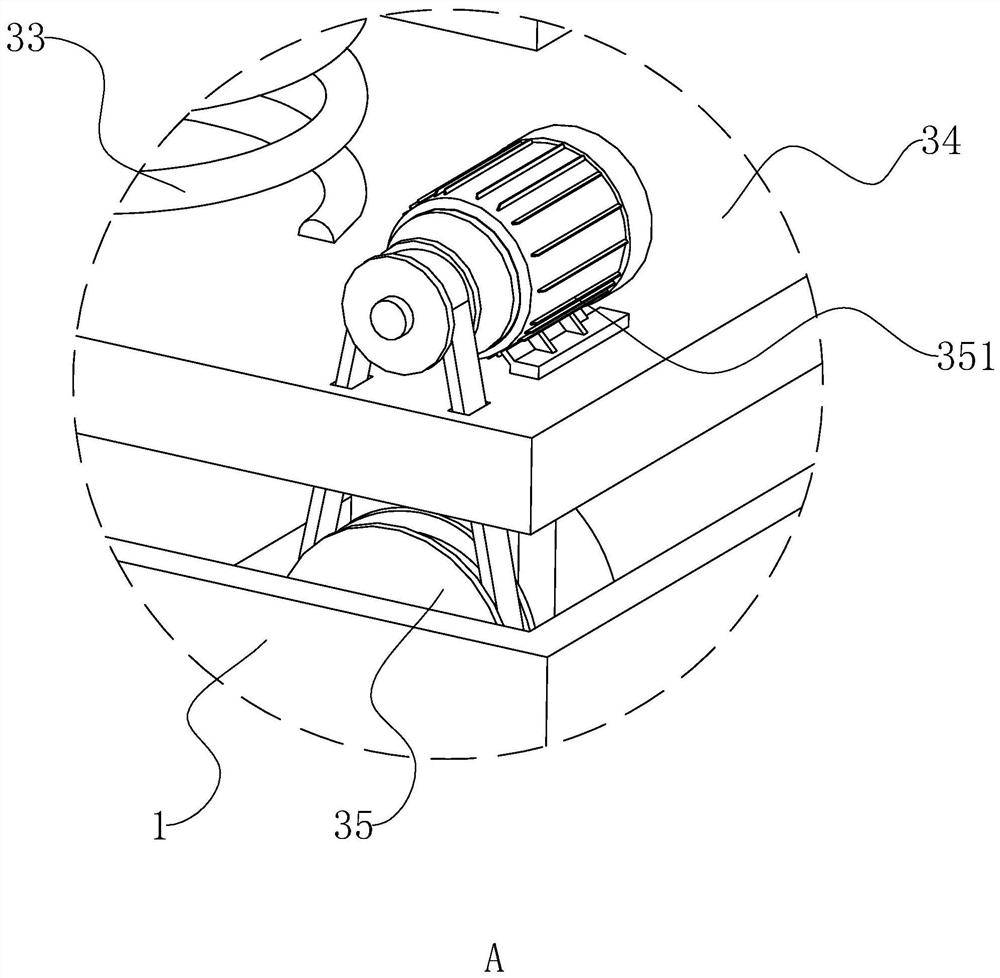

[0048] This embodiment discloses a floating washing machine, such as figure 1 and figure 2 As shown, it mainly includes a floating washing tank 1, a cleaning roller part 2, a pressing part 3 and a liquid inlet part 4. The cleaning roller part 2 includes a first horizontal row roller 21 and a second horizontal row roller 22. At the same time, the first horizontal row The rollers 21 are rotatably arranged between the relative vertical side walls of the floating washing tank 1. In this embodiment, there is a row of the first horizontal rollers 21, and there are eight first horizontal rollers 21 in a row, and eight first horizontal rollers The rollers 21 are parallel to each other and arranged in the horizontal direction; the second horizontal row roller 22 is also rotated and arranged between the relative vertical side walls of the floating washing tank 1 and is parallel to the first horizontal row roller 21, and the second horizontal row roller 22 also has a Row, there are nin...

Embodiment 2

[0066] The difference between embodiment two and embodiment one is:

[0067] The floating washing liquid raw material in step S2-1 comprises the following components by weight: 180 parts of water, 9 parts of emulsifier PE-101, 25 parts of sodium dodecylbenzenesulfonate, 18 parts of disodium EDTA, dimethyl carbonate 22 parts of ester, 23 parts of triethanolamine oleate.

Embodiment 3

[0069] The difference between embodiment three and embodiment one is:

[0070] The floating washing liquid raw material in step S2-1 comprises the following components by weight: 200 parts of water, 14 parts of emulsifier PE-101, 30 parts of sodium dodecylbenzenesulfonate, 21 parts of disodium EDTA, dimethyl carbonate 33 parts, 31 parts of triethanolamine oleate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com