Preparation method of fragment convergence type bulletproof composite material

A technology of bulletproof composite materials and fragments, which is applied in the direction of protective equipment, chemical instruments and methods, protective clothing, etc., can solve the problems of poor flame retardancy, poor mechanical properties, high-speed fragment protection performance and limited astringent effect, and achieve radiation shielding The effect of excellent performance, excellent vibration and noise reduction ability, and excellent radiation protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

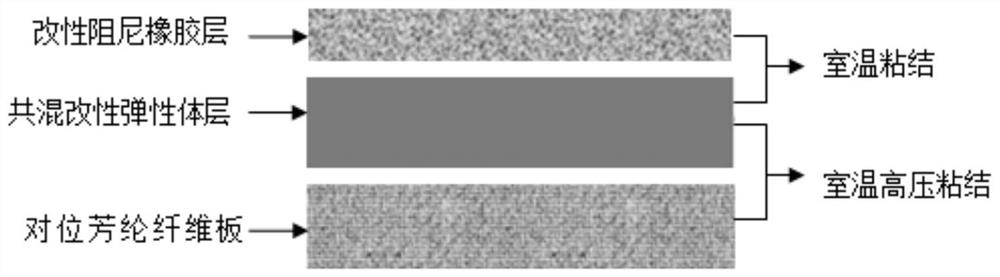

[0034] A method for preparing a fragment-convergent bulletproof composite material is carried out as follows:

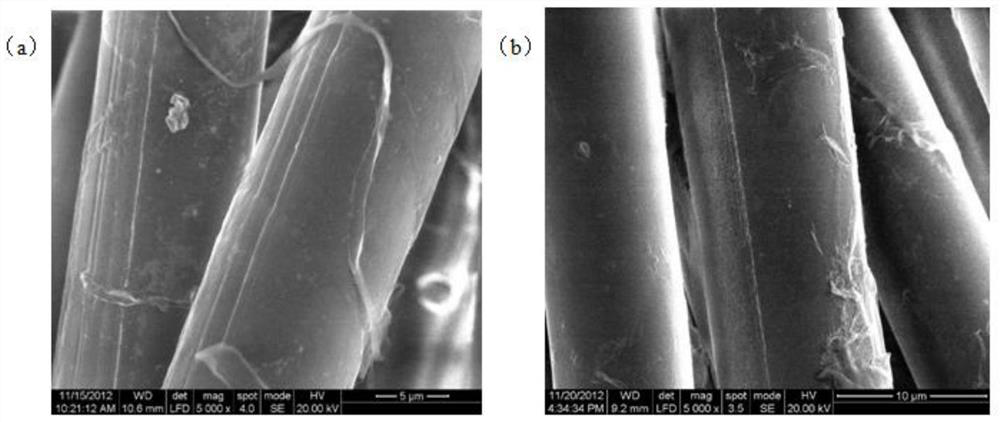

[0035] S1. Preparation of aramid fiber braided structure

[0036] (1) Pretreatment of aramid fibers: put the aramid fibers in a sodium hydroxide solution with a mass fraction of 0.5%, take them out after soaking for 70 minutes, wash them with deionized water until neutral, then put them in acetone, and soak for 12 hours Finally, take it out, wash it three times with deionized water, then put it in deionized water and cook for 15 minutes, take it out and put it in an oven to dry, set the temperature at 110°C for 20 minutes, take it out and put it in a sealed bag for later use;

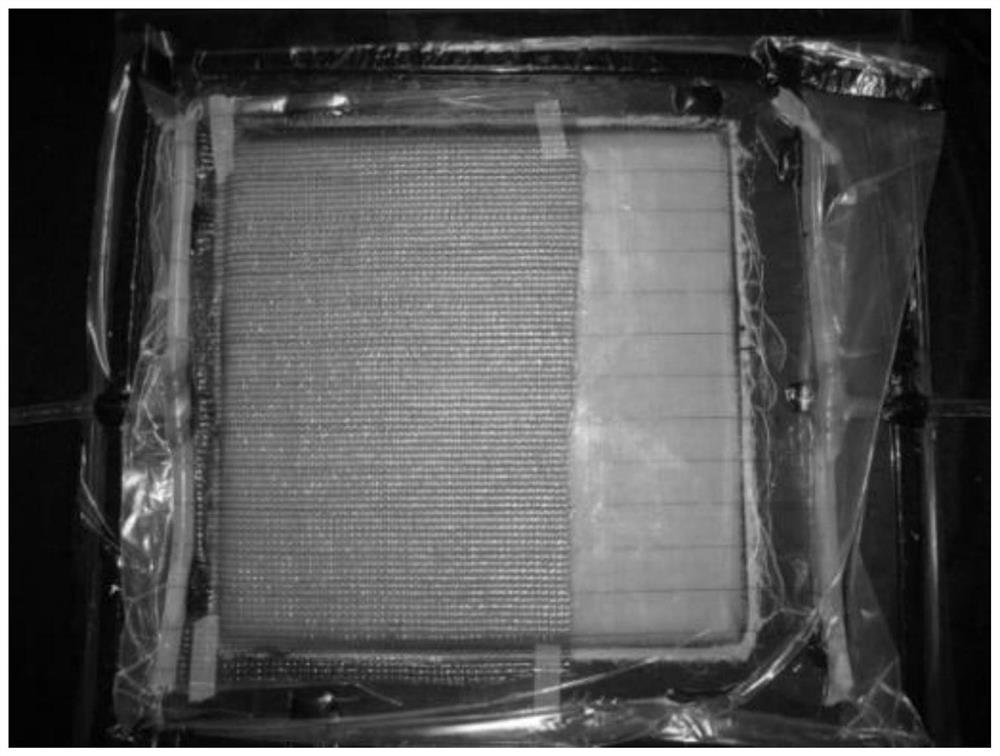

[0037] (2) Shallow cross-linked 2.5D weaving structure: the pretreated para-aramid fiber is divided into warp yarns and weft yarns perpendicular to each other for weaving. The warp yarns are in a curved state, the weft yarns are in a straight state, and the warp yarns are along the vertical pl...

Embodiment 2

[0048] A method for preparing a fragment-convergent bulletproof composite material is carried out as follows:

[0049] S1. Preparation of aramid fiber braided structure

[0050] (1) Pretreatment of aramid fiber: put the aramid fiber in a sodium hydroxide solution with a mass fraction of 0.5%, take it out after soaking for 1 hour, wash it with deionized water until it is neutral, put it in acetone, and soak it for 12 hours Then take it out, wash it with deionized water, put it into deionized water and cook for 15 minutes, take it out and put it in an oven to dry, set the temperature at 110°C for 20 minutes, take it out and put it in a sealed bag for later use.

[0051] (2) Shallow cross-linked 2.5D weaving structure: the pretreated para-aramid fiber is divided into warp yarns and weft yarns perpendicular to each other for weaving. The warp yarns are in a curved state, the weft yarns are in a straight state, and the warp yarns are along the vertical plane and thickness of the fa...

Embodiment 3

[0059] A method for preparing a fragment-convergent bulletproof composite material is carried out as follows:

[0060] S1. Preparation of aramid fiber braided structure

[0061] (1) Pretreatment of aramid fibers: put aramid fibers in a sodium hydroxide solution with a mass fraction of 0.5%, take them out after soaking for 1.5 hours, wash them with deionized water until neutral, then put them in acetone, soak After 12 hours, take it out, wash it with deionized water, then boil it in deionized water for 15 minutes, take it out and put it in an oven to dry, set the temperature at 110°C for 20 minutes, take it out and put it in a sealed bag for later use.

[0062] (2) Shallow cross-linked 2.5D weaving structure: the pretreated para-aramid fiber is divided into warp yarns and weft yarns perpendicular to each other for weaving. The warp yarns are in a curved state, the weft yarns are in a straight state, and the warp yarns are along the vertical plane and thickness of the fabric. C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com