Pyrochlore nanocrystalline dielectric film with ultrahigh energy storage performance and preparation method of the pyrochlore nanocrystalline dielectric film

A technology of pyrochlore and nanocrystals, applied in the direction of fixed capacitor dielectrics, circuits, capacitors, etc., can solve the problems of low electric field breakdown strength and achieve the effects of improved breakdown strength, simple process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

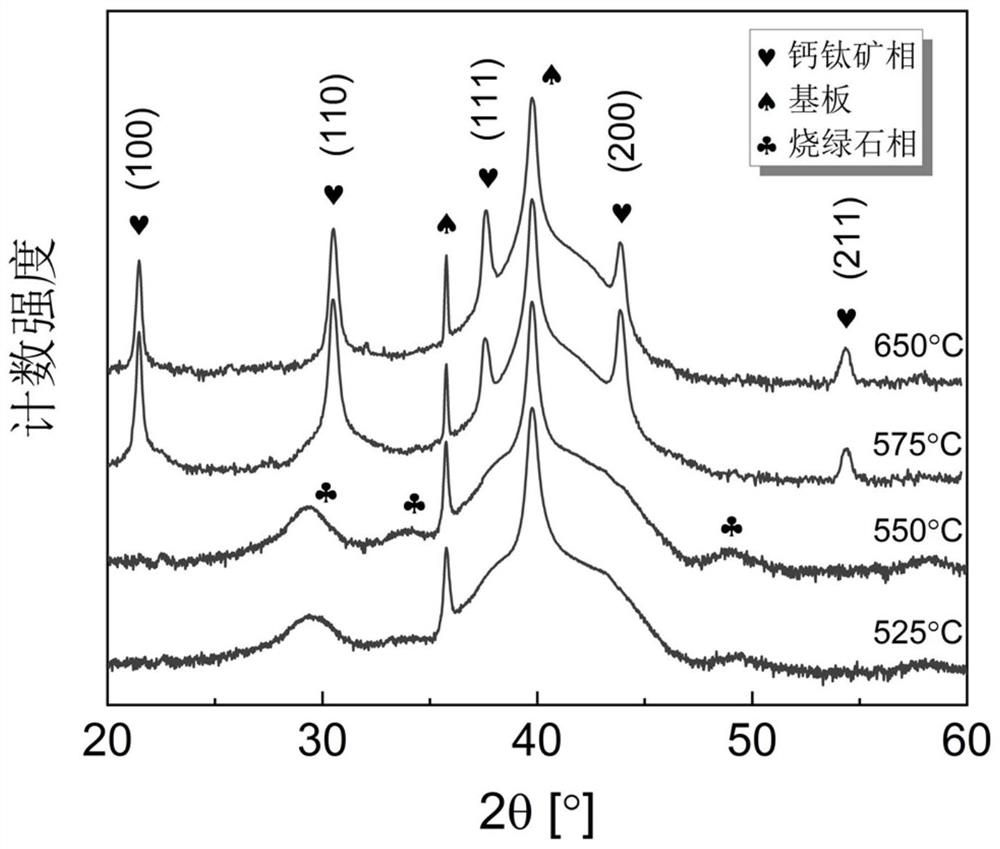

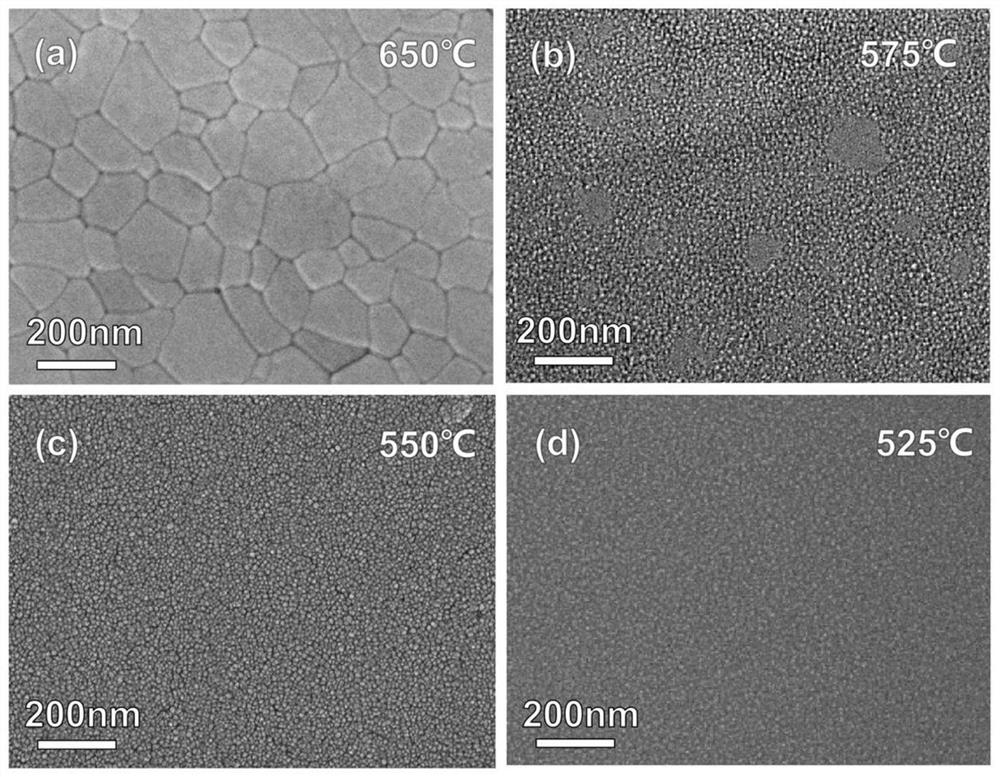

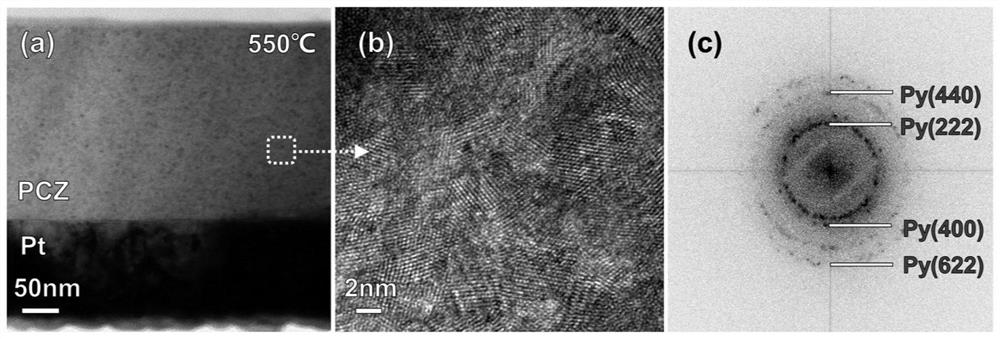

[0030] Samples annealed at 550°C

[0031] Step 1: Prepare the solution

[0032] Use ethylene glycol methyl ether (2-MOE) as solvent. Lead acetate (Pb(CH 3 COO) 2 ·3H 2 O), calcium nitrate (Ca(NO 3 ) 2 4H 2 O) and zirconium n-propoxide (Zr(OCH 2 CH 2 CH 3 ) 4 ) as the solute, according to the atomic ratio of Pb:Ca:Zr 0.88:0.12:1, take lead acetate, calcium nitrate and zirconium n-propoxide. Add ethylene glycol methyl ether to lead acetate and calcium nitrate at a concentration of 0.2M, distill at 120°C for 2 hours, then cool to room temperature, add zirconium n-propoxide, stir at room temperature for 2 hours, and finally add ethyl Glycol methyl ether supplements the solvent loss caused by the distillation process, so that the solution concentration reaches 0.2M, and a light yellow transparent solution is obtained;

[0033] Step 2: Preparation of film material

[0034] (1) Using Pt(111) / Ti / SiO 2 / Si substrate. Spin-coat the solution prepared in step 1 onto the sub...

Embodiment 2

[0039] Samples annealed at 575°C

[0040] Step 1: Prepare the solution

[0041] Use ethylene glycol methyl ether (2-MOE) as solvent. Lead acetate (Pb(CH 3 COO) 2 ·3H 2 O), calcium nitrate (Ca(NO 3 ) 2 4H 2 O) and zirconium n-propoxide (Zr(OCH 2 CH 2 CH 3 ) 4 ) as the solute, according to the atomic ratio of Pb:Ca:Zr 0.88:0.12:1, take lead acetate, calcium nitrate and zirconium n-propoxide. Add ethylene glycol methyl ether to lead acetate and calcium nitrate at a concentration of 0.2M, distill at 120°C for 2 hours, then cool to room temperature, add zirconium n-propoxide, stir at room temperature for 2 hours, and finally add ethyl Glycol methyl ether supplements the solvent loss caused by the distillation process, so that the solution concentration reaches 0.2M, and a light yellow transparent solution is obtained;

[0042] Step 2: Preparation of film material

[0043] (1) Using Pt(111) / Ti / SiO 2 / Si substrate. Spin-coat the solution prepared in step 1 onto the sub...

Embodiment 3

[0048] Samples annealed at 525°C

[0049] Step 1: Prepare the solution

[0050] Use ethylene glycol methyl ether (2-MOE) as solvent. Lead acetate (Pb(CH 3 COO) 2 ·3H 2 O), calcium nitrate (Ca(NO 3 ) 2 4H 2 O) and zirconium n-propoxide (Zr(OCH 2 CH 2 CH 3 ) 4 ) as the solute, according to the atomic ratio of Pb:Ca:Zr 0.88:0.12:1, take lead acetate, calcium nitrate and zirconium n-propoxide. Add ethylene glycol methyl ether to lead acetate and calcium nitrate at a concentration of 0.2M, distill at 120°C for 2 hours, then cool to room temperature, add zirconium n-propoxide, stir at room temperature for 2 hours, and finally add ethyl Glycol methyl ether supplements the solvent loss caused by the distillation process, so that the solution concentration reaches 0.2M, and a light yellow transparent solution is obtained;

[0051] Step 2: Preparation of film material

[0052] (1) Using Pt(111) / Ti / SiO 2 / Si substrate. Spin-coat the solution prepared in step 1 onto the sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com