Zinc-doped tin oxide transparent conductive thin film and preparation method and application thereof

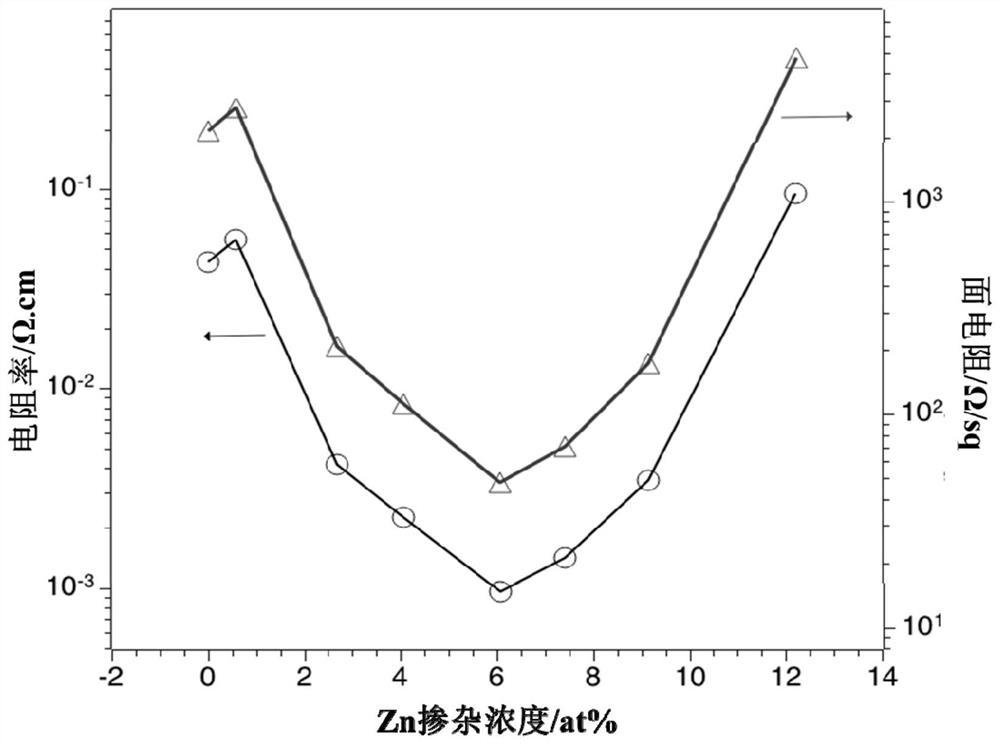

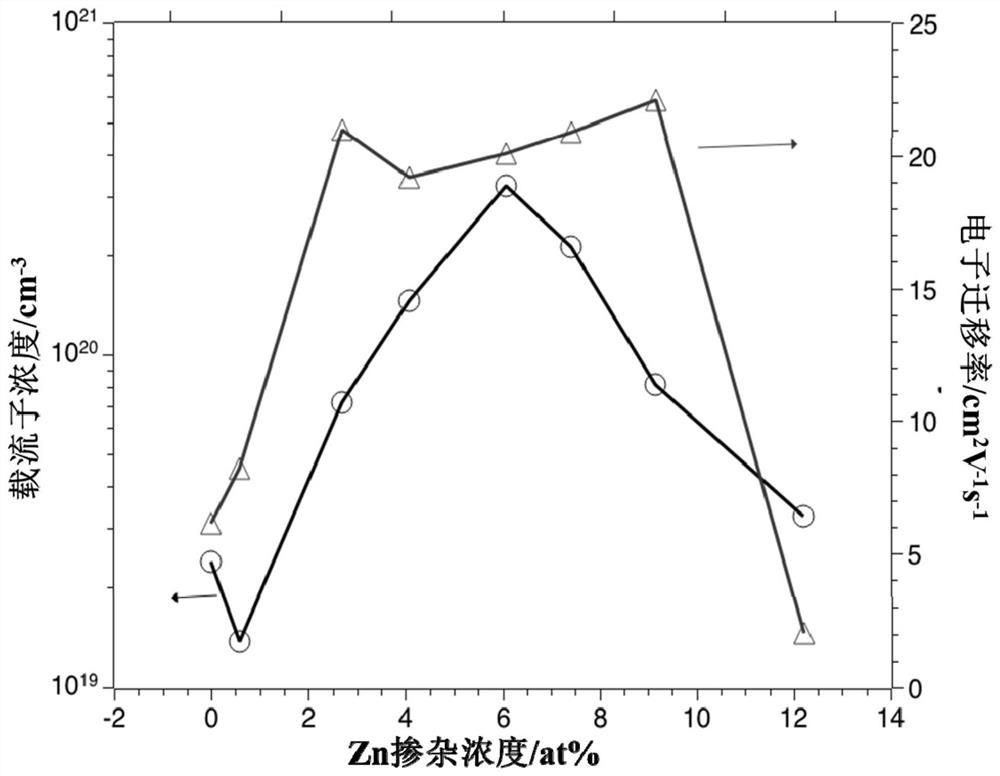

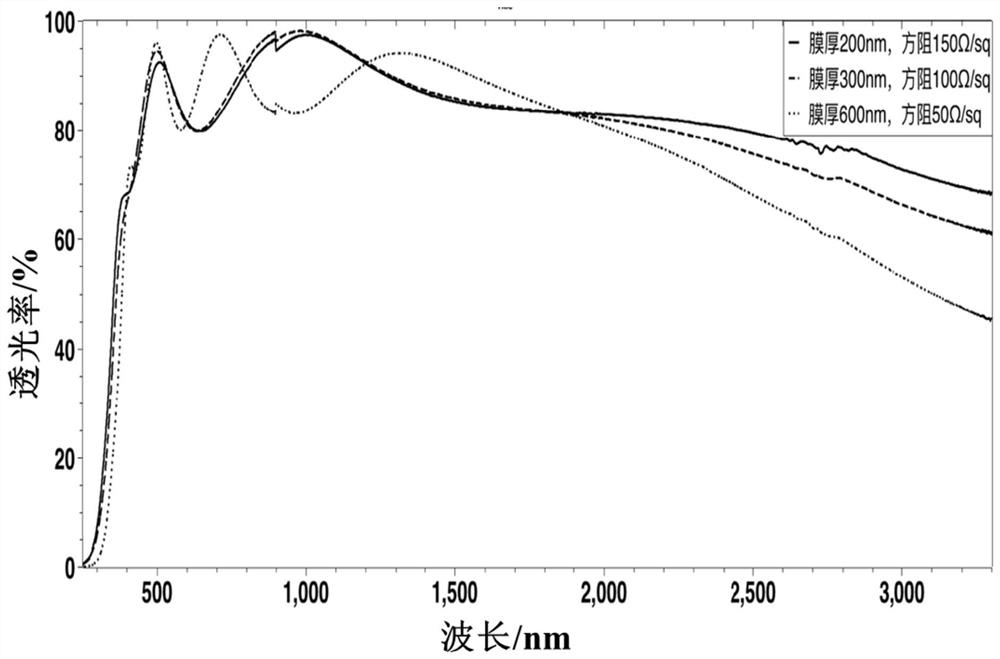

A transparent conductive film, tin oxide technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problem of high carrier concentration and electron mobility, low resistivity and sheet resistance, thermal stability Insufficient chemical resistance and acid resistance, etc., to achieve high carrier concentration and electron mobility, low resistivity and sheet resistance, and improve chemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] This embodiment provides a method for preparing a zinc-doped tin oxide transparent conductive film, the preparation method comprising the following steps:

[0071](1) Choose a glass sheet with a thickness of 1.1mm as the substrate, and cut it into a size of 10mm×10mm, and then carry out ethanol cleaning, deionized water cleaning and drying on the substrate as pretreatment, wherein, first Ultrasonic cleaning in ethanol for 15 minutes, then ultrasonic cleaning in deionized water for 15 minutes, and then drying it with nitrogen gas with a purity ≥ 99.999%, and then placing the substrate on a substrate tray in a vacuum reaction chamber; Tin is used as the organic tin source and placed in a stainless steel bubbler, and the freezing solution is used for freezing treatment, and the temperature of the freezing treatment is controlled at 10°C; diethyl zinc is used as the organic zinc source and placed in another stainless steel bubbler , use freezing liquid to carry out freezing...

Embodiment 2

[0076] This embodiment provides a method for preparing a zinc-doped tin oxide transparent conductive film, the preparation method comprising the following steps:

[0077] (1) Choose a quartz sheet with a thickness of 1.1mm as the substrate, and cut it into a size of 50mm×50mm, and carry out ethanol cleaning, deionized water cleaning and drying on the substrate successively as pretreatment, wherein, first Ultrasonic cleaning in ethanol for 20 minutes, then ultrasonic cleaning in deionized water for 20 minutes, then blowing it dry with nitrogen gas with a purity ≥ 99.999%, and then placing the substrate on a substrate tray in a vacuum reaction chamber; Tin is used as the organic tin source and placed in a stainless steel bubbler, and the freezing solution is used for freezing treatment, and the temperature of the freezing treatment is controlled at 15°C; diethyl zinc is used as the organic zinc source and placed in another stainless steel bubbler , use freezing liquid to carry o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Carrier concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com