Capillary steam-doped super-cavitation jet noise suppression device

A noise suppression and capillary technology, applied in the field of jet noise reduction suppression devices, can solve the problems of excessive flow noise fluctuation and large overall sound power, and achieve the effects of reducing the number of cavitations, increasing local pressure, and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings and implementation.

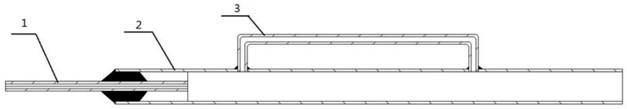

[0020] See figure 1 , The capillary steam doping supercavitation jet noise suppression device includes a throttle capillary 1, an evaporator inlet transition pipe 2, a bypass capillary a, the outer diameter of the bypass capillary a is 1.8-2.5mm, and the inner diameter is 0.6-0.7mm , The total length of the bypass capillary a is 200mm, the length of the bypass capillary a inserted into the front end of the evaporator inlet transition tube 2 is 10mm, and the distance between the inserted front end and the outlet of the throttle capillary 1 is 10mm; the bypass capillary a is inserted into the evaporator inlet transition tube 2 The length of the rear end is 10mm, and the distance between the insertion rear end and the outlet of the throttle capillary 1 is 170mm, and the connection method of each part is oxygen welding.

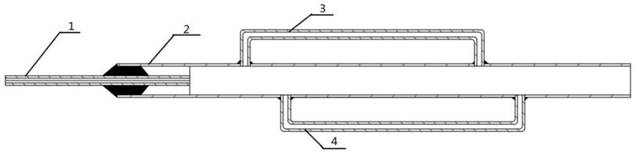

[0021] See figure 2 , The capillary steam doping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com