Metal-sulfur battery electrolyte and metal-sulfur battery containing same

A metal sulfur and electrolyte technology, which is applied in the field of metal sulfur battery electrolyte and metal sulfur battery, can solve the problems affecting the stability of battery cycle performance, the dissolution of positive electrode sulfur, etc., to reduce the shuttle effect, inhibit corrosion, and improve cycle stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This example is used to illustrate the representative metal-sulfur battery electrolyte and metal-sulfur battery of the present invention.

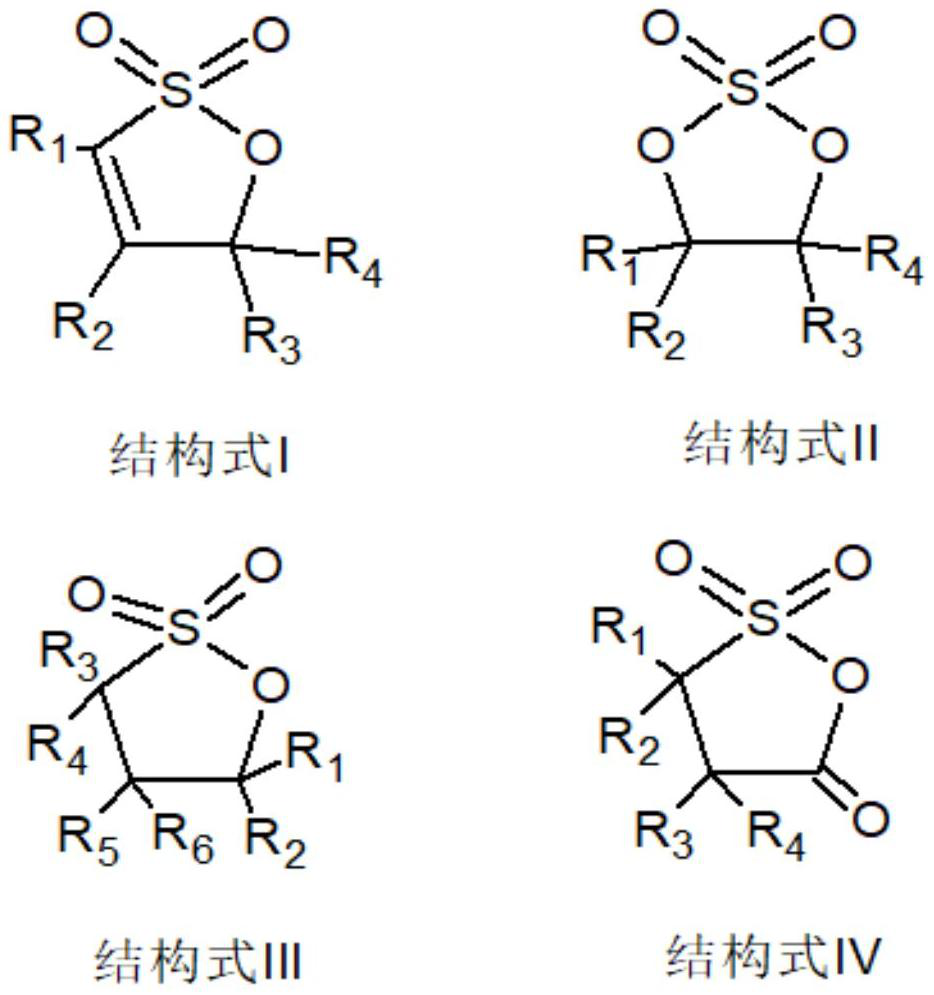

[0049] 1. Preparation of Electrolyte for Metal Sulfur Battery

[0050] 1,3-dioxolane (DOL) and dimethyl carbonate (DMC) were mixed at a volume ratio of 1:1 to form a mixed solvent. Add lithium bisfluorosulfonimide (LiTFSI) to the mixed solvent to a concentration of 1M, and add the above-mentioned structural formula I 1 The indicated compounds to a concentration of 1 wt% and the addition of LiNO 3 To the concentration of 1wt%, stir evenly, obtain and comprise 1:1DOL:DME+1MLiTFSI+1wt% structural formula I 1 Compounds shown + 1wt% LiNO 3 The metal-sulfur battery electrolyte is shown in Table 1.

[0051] 2. Fabrication of metal-sulfur batteries

[0052] (1) Preparation of positive electrode

[0053] Mix elemental sulfur and Ketjen black at a mass ratio of 1:3, and heat at 155°C for 12 hours. During the heating process, due to the ...

Embodiment 2-24

[0057] Examples 2-24 are used to illustrate other metal-sulfur battery electrolytes and metal-sulfur batteries of the present invention, and their preparation is similar to the preparation method of the metal-sulfur battery electrolyte and metal-sulfur batteries in Example 1. The components and contents shown in 1 were used to prepare metal-sulfur battery electrolyte, and the metal-sulfur battery was prepared using the prepared metal-sulfur battery electrolyte, the positive electrode obtained in Example 1, the negative electrode shown in Table 1, and the celgard2325 type diaphragm ( lithium-sulfur battery, potassium-sulfur battery or sodium-sulfur battery).

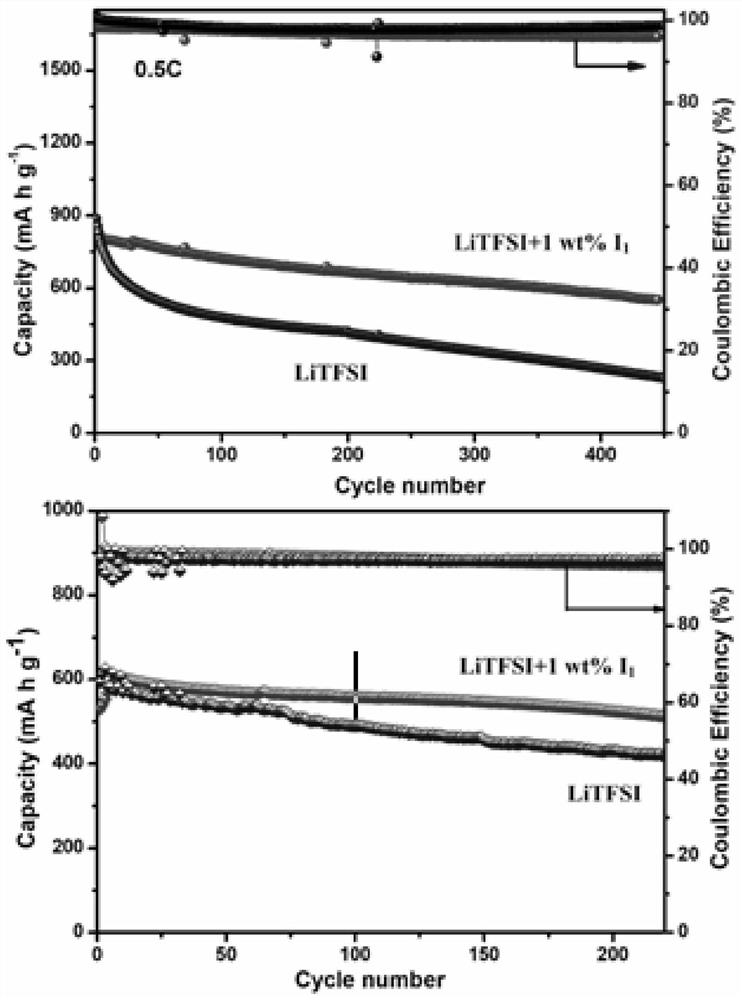

Embodiment 2

[0071] Embodiment 2 (sodium-sulfur battery, containing 1M NaTFSI sodium salt) and embodiment 3 (potassium-sulfur battery, containing 1M KTFSI potassium salt) add 1wt% of the compound shown in structural formula I to the electrolyte solution containing 1:1DOL / DME solvent , while Comparative Example 2 (sodium-sulfur battery, containing 1M NaTFSI sodium salt) and Comparative Example 3 (potassium-sulfur battery, containing 1M KTFSI potassium salt) did not add 1wt% of the compound shown in structural formula I in the corresponding electrolyte. Comparing the test results of Example 2-3 and Comparative Example 2-3, it can be seen that after the sodium-sulfur battery of Example 2 and the potassium-sulfur battery of Example 3 cycled 200 and 450 times at 0.5C and 230 times at 2C, The battery capacity is better than the sodium-sulfur battery of Comparative Example 2 and the potassium-sulfur battery of Comparative Example 3, indicating that the compound shown in structural formula I can im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com