Method for treating kettle residues in industrial preparation of butyryl chloride

A treatment method, the technology of butyryl chloride kettle, which is applied in the field of organic synthesis and chemical "three wastes" treatment, can solve environmental pollution and other problems, achieve the effect of improving economic benefits and eliminating odor pollution sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

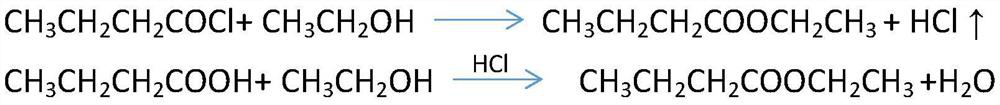

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 (laboratory scale)

[0031] Put 196g of the still residue from the industrial preparation method of butyryl chloride synthesis by the reaction of butyric acid and phosphorus trichloride into a 500ml reaction bottle, slowly add 150g (3.22mol) of absolute ethanol dropwise for about 2 hours, dropwise In the initial stage, the heat is exothermic violently, and white smoke is released. Control the reaction temperature between 25 and 50°C, stop the dropwise addition when the dropwise addition is no longer exothermic, stir for 1 hour, and distill the reaction liquid under reduced pressure. The pressure is -0.06MPa, 41°C Take out the distillate, steam to 90°C and no distillate flows out, and end the distillation. During the distillation process, there is a fruity aroma.

[0032] After testing, a total of 224.0 g of the organic phase was evaporated, which was colorless and transparent, with a fruity aroma, and was identified as ethyl butyrate. GC detection purity: ...

Embodiment 2

[0033] Embodiment 2 (laboratory scale)

[0034]Put 196g of the still residue from the industrial preparation method of butyryl chloride synthesis by the reaction of butyric acid and phosphorus trichloride into a 500ml reaction bottle, and slowly add 110g (3.44mol) of anhydrous methanol dropwise for about 2 hours. In the initial stage, the heat is exothermic violently, and white smoke is released. Control the reaction temperature between 25 and 50°C, stop the dropwise addition when the dropwise addition is no longer exothermic, stir for 1 hour, distill the reaction solution under reduced pressure, the pressure is -0.06MPa, and exit at 38°C. Distillate fractions, steamed to 85 ° C, no fractions flow out, the distillation is over, and there is a fruity aroma during the distillation process.

[0035] After testing, a total of 192.0 g of the organic phase was evaporated, which was colorless and transparent, with a fruity aroma. After identification, the organic phase was methyl but...

Embodiment 3

[0036] Embodiment 3 (industrial scale)

[0037] Put 800kg of still residue from the industrial preparation method of synthesizing butyryl chloride with butyric acid and phosphorus trichloride into a 2000L enamel reaction kettle, and slowly add 593kg (12.9kmol) of absolute ethanol dropwise for about 3 hours. At the beginning of the dropwise addition, there is a violent exotherm, and white smoke is emitted. Control the reaction temperature between 25 and 50°C. Stop the dropwise addition when the dropwise addition is no longer exothermic, stir for 2 hours, and distill the reaction solution under reduced pressure. The pressure is -0.06MPa, 40°C Take out the distillate, steam to 90°C and no distillate flows out, and end the distillation. During the distillation process, there is a fruity aroma.

[0038] After testing, a total of 958.0 kg of organic phase was evaporated, which was colorless and transparent, with a fruity aroma, and was identified as ethyl butyrate. GC detection pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com