Preparation method of O, O '-dimethyl thiophosphamide

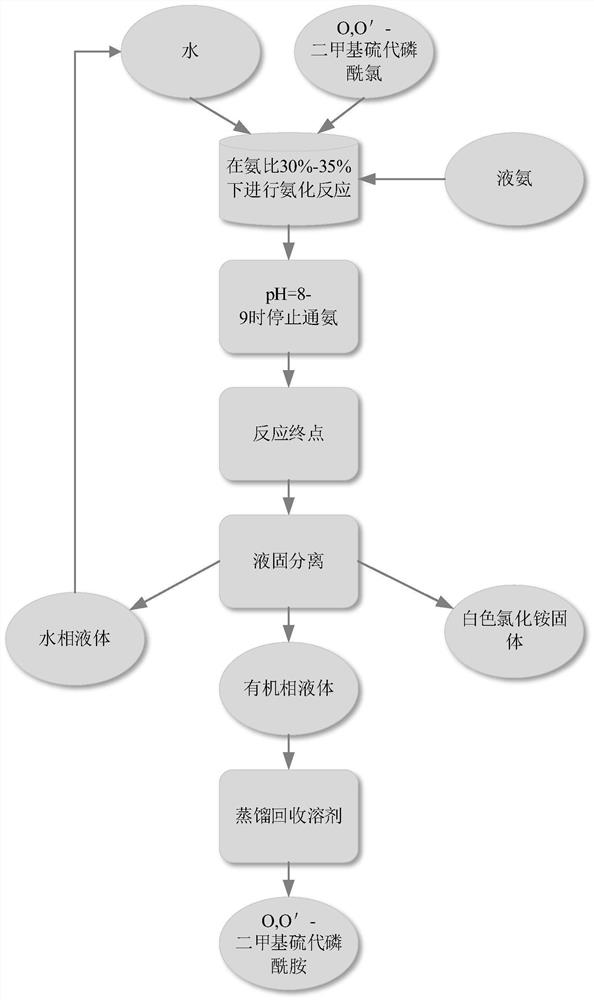

A technology of dimethyl thiophosphoramide and dimethyl thiophosphoryl, which is applied in the field of preparation of O,O'-dimethyl thiophosphorylamide, can solve the problem that sewage is difficult to treat, discharge is difficult to meet standards, and ammonia concentration is difficult to achieve. low problems, to achieve the effect of fast response, low cost and improved economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Put 210 kg of water and 1050 kg of O, O'-dimethylphosphorothioate (content 92.5%) into a 3000-liter glass-lined reaction pot, start the stirring blade and directly feed liquid ammonia at a temperature of 15 ° C, and pass the ammonia pressure It is 0.15kPa, and the ammonia ratio is controlled to be 30%. When the pH value of the reaction solution reaches 8-9, the ammonia flow is stopped until the end point. The ammonia reaction time is 2 hours, and then the discharge is centrifuged, and the solid ammonium chloride is rinsed with cold water at 0-5°C; the liquid part is the organic phase mainly composed of O,O'-dimethylthiophosphoramide and the ammonium chloride solution. A mixed liquid formed from an aqueous phase. The mixed liquid is transferred to the separator for separation, and the water phase is sent to the reaction pot for continued production and use. After being recycled and supersaturated, the solid ammonium chloride is recovered by filtration, and the water phas...

Embodiment 2

[0028] Put 1300 kg of water and 800 kg of O, O'-dimethyl thiophosphoryl chloride (92.5% content) into a 3000-liter glass-lined reaction pot, start the stirring paddle at a temperature of 40°C and directly feed ammonia to the ammonia pressure It is 0.17kPa, and the ammonia ratio is controlled to be 32%. When the pH value of the reaction solution reaches 8-9, the ammonia flow is stopped until the end point. The ammonia reaction time is 2.5 hours, and then the material is centrifuged, and the liquid part is a mixed liquid formed by an organic phase mainly composed of O, O'-dimethylphosphorothioate and an aqueous phase of an ammonium chloride solution. The mixed liquid is transferred to the separator for separation, and the water phase is sent to the reaction pot for continued production and use. After being recycled and supersaturated, the solid ammonium chloride is recovered by filtration, and the water phase is continued for production and use. After the organic phase is post-t...

Embodiment 3

[0030] Put 520 kg of water into a 3000-liter glass-lined reaction pot, then add 1300 kg of O, O'-dimethylphosphoryl thiochloride (content 99.5%), start the stirring blade and directly feed ammonia at 0°C. The ammonia pressure is 0.18kPa, and the ammonia ratio is controlled to be 35%. When the pH value of the reaction solution reaches 8-9, the ammonia flow is stopped until the end point. The ammonia reaction time is 2.5 hours, and then the material is centrifuged, and the liquid part is a mixed liquid formed by an organic phase mainly composed of O, O'-dimethylphosphorothioate and an aqueous phase of an ammonium chloride solution. The mixed liquid is transferred to the separator for separation, and the water phase is sent to the reaction pot for continued production and use. After being recycled and supersaturated, the solid ammonium chloride is recovered by filtration, and the water phase is continued for production and use. After the organic phase is post-treated, it is refin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com