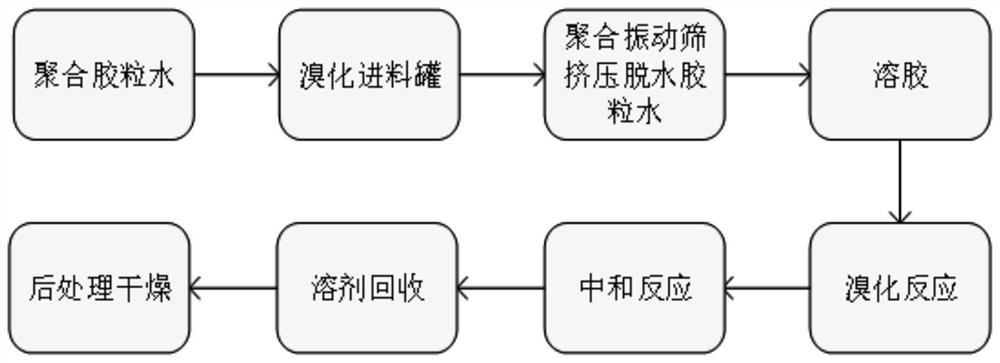

Production process of brominated butyl rubber

A technology of bromobutyl rubber and production process, applied in the rubber field, can solve problems such as affecting production efficiency, easy hanging on walls, forced shutdown, etc., so as to improve hexane recovery efficiency, improve operation cycle, and reduce hexane unit consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

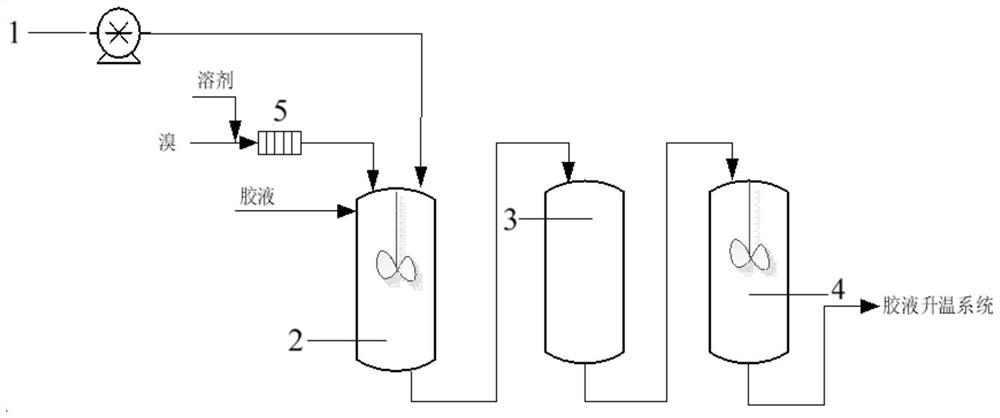

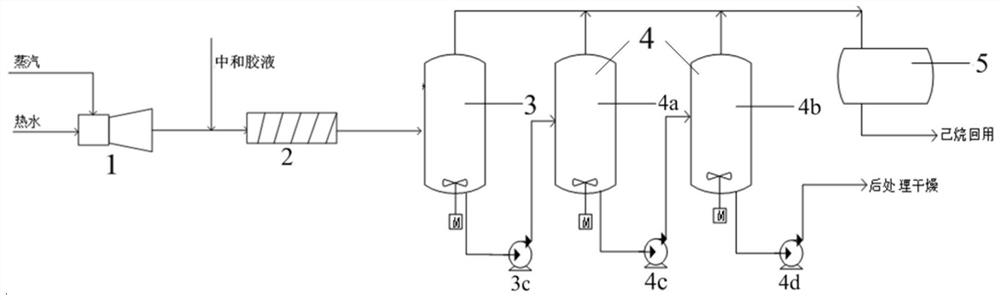

[0111] On the basis of comparative example 1, before flashing, increase the temperature of glue liquid heating system, before bromination, increase nitrogen pressurization system, and flash tank structure is improved (using Figure 5 The shown flash tank, wherein, the angle α of the spray port is 60°, and the baffle is a triangular baffle), specifically according to figure 2 and image 3 The shown bromination-neutralization process and solvent recovery process are carried out, and the others are the same as in Comparative Example 1. details as follows:

[0112] S1. Preparation of sol: IIR basic colloidal water is obtained by cationic polymerization of isobutylene and isoprene, which is transported to the halogenated feed storage tank through the colloidal water pump, squeezed and dehydrated by vibrating screen and screw machine, and then passed through cold and hot hexane The glue concentration was prepared to obtain a sol with a set concentration (concentration is 20wt%). ...

Embodiment 2~3

[0120] The operation is carried out according to Example 1, the difference is that the hot water flow rate and steam flow rate of the steam-water mixer are different, resulting in different hot water temperature and glue temperature after mixing. The specific conditions are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com