Polypropylene composite material and preparation method and application thereof

A composite material and polypropylene technology, applied in the field of polypropylene composite materials and its preparation, can solve the problems of not suitable for instrument panels and low impact strength of notched cantilever beams, achieve good heat resistance, improve impact performance, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

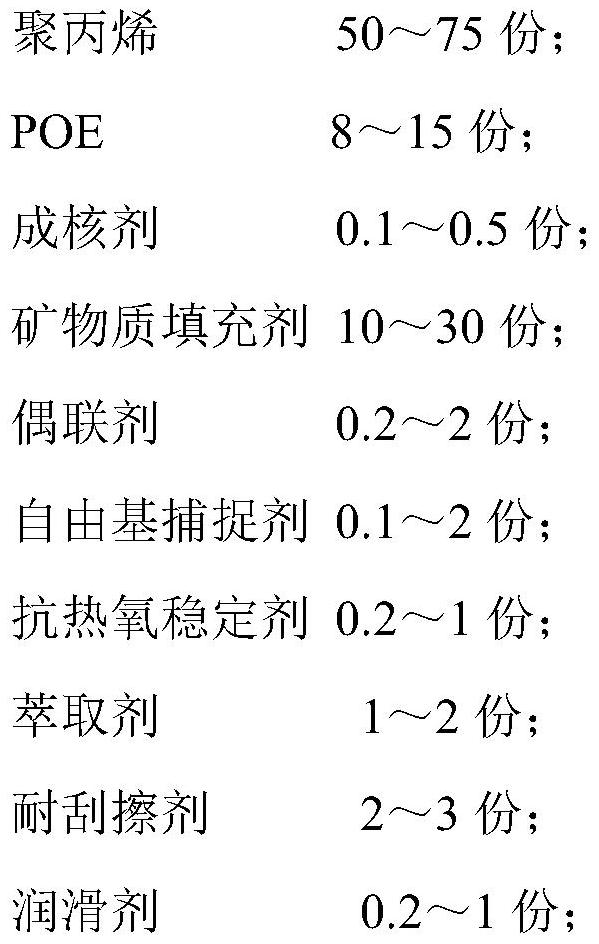

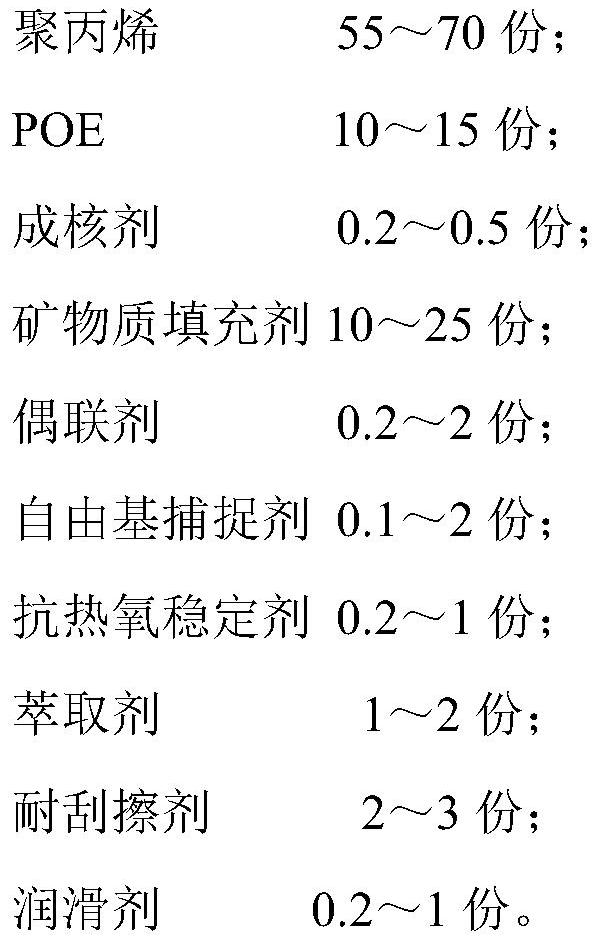

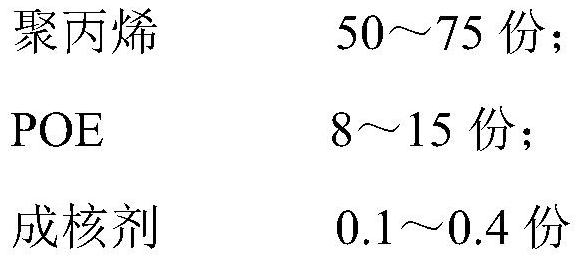

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a polypropylene composite material, including the raw materials shown in Table 1.

[0045] Among them, the polypropylene is copolymerized polypropylene 7033E3, MI is 8g / 10min (230°C / 2.16kg), flexural modulus is 1140MPa, impact strength is 280J / m, ExxonMobil.

[0046] POE is ethylene elastomer ENGAGE TM 8842, MI is 1.0g / 10min (190°C / 2.16kg), Dow Chemical.

[0047] The nucleating agent is CS-9503, a nucleating agent for amide-type polypropylene beta crystal form, Hangzhou Jufeng New Materials.

[0048] The mineral filler is talc.

[0049] The coupling agent is KH-550.

[0050] The anti-thermal oxygen stabilizer is a compound composed of anti-thermal oxygen stabilizer 1010 and 168 with a mass ratio of 2:1.

[0051] The free radical scavenger is UV-3808; the extractant is BYK-P4200, BYK, Germany; the anti-scratch agent is silicone masterbatch MB50-001, Dow Corning; the lubricant is EBS.

[0052] The preparation method of the present embodiment...

Embodiment 2

[0056] This embodiment provides a polypropylene composite material, the raw material composition of which is shown in Table 1.

[0057] in,

[0058] The polypropylene is copolymerized polypropylene BH975MO, MI is 38g / 10min (230°C / 2.16kg), flexural modulus is 1420MPa, Borouge Chemicals.

[0059] POE is ethylene elastomer ENGAGE TM 8150, MI melt index is 1.0g / 10min (190℃ / 2.16kg), Dow Chemical.

[0060] Mineral fillers are whiskers.

[0061] Other raw materials are selected with embodiment 1.

[0062] The preparation method of the polypropylene of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0064] This embodiment provides a polypropylene composite material, the raw material composition of which is shown in Table 1.

[0065] in,

[0066] Polypropylene is copolymerized polypropylene BH3820, MI is 28g / 10min (230℃ / 2.16kg), flexural modulus is 981MPa, impact strength is 490J / m, Korea SK;

[0067] The mineral filler is mica.

[0068] Other raw materials are selected with embodiment 1.

[0069] The preparation method of the polypropylene of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com