A kind of nbc/fe2b composite gradient wear-resistant coating and preparation method thereof

A technology of wear-resistant coating and composite coating, which is applied in the direction of coating, metal material coating process, solid-state diffusion coating, etc., to achieve the effects of reducing boronizing temperature, increasing thickness, and reducing diffusion energy barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] For NbC / Fe 2 B Composite gradient wear-resistant coating prepared steel materials with cementite as the strengthening phase (the mass fraction of carbon is 0.3%) for surface treatment, including rust removal, oil removal, and if there are cracks on the surface, first turn to eliminate cracks layer;

[0018] Pure Nb rods are used as electrode materials for EDM deposition to obtain NbC strengthened nanocrystalline coatings. During the deposition process, inert gas is used for protection. The specific process parameters of deposition are: output power 1500W, output voltage 200V, deposition rate 7min / cm 2 .

[0019] The workpiece obtained in the previous step is boronized by solid boronizing process, wherein the boronizing agent is LSB-II type boronizing agent, and the boronizing process parameters are: boronizing temperature 850°C, boronizing holding time is 300min .

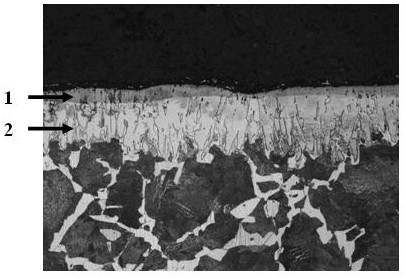

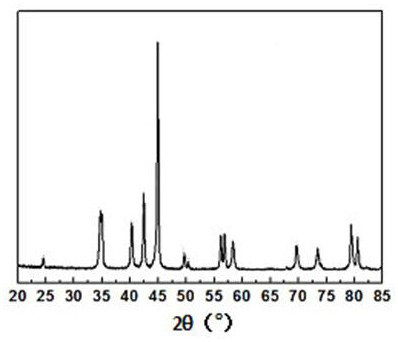

[0020] The composite gradient wear-resistant coating finally prepared contains NbC and Fe 2 B Two ki...

Embodiment 2

[0023] For NbC / Fe 2 B The iron and steel material with cementite as the strengthening phase prepared by the composite gradient wear-resistant coating (the mass fraction of carbon is 1.2%) is subjected to surface treatment, including rust removal, oil removal, and if there are cracks on the surface, first turn to eliminate cracked layer;

[0024] Pure Nb rods are used as electrode materials for EDM deposition to obtain NbC-strengthened nanocrystalline coatings. During the deposition process, inert gas is used for protection. The specific process parameters of deposition are: output power 3000W, output voltage 300V, deposition rate 0.5min / cm 2 .

[0025] The workpiece obtained in the previous step is boronized by solid boronizing process, wherein the boronizing agent is LSB-II type boronizing agent, and the boronizing process parameters are: boronizing temperature 1000°C, boronizing holding time is 100min .

[0026] The composite gradient wear-resistant coating finally prepa...

Embodiment 3

[0028] For NbC / Fe 2 B The iron and steel material with cementite as the strengthening phase prepared by the composite gradient wear-resistant coating (the mass fraction of carbon is 0.8%) is subjected to surface treatment, including rust removal, oil removal, and if there are cracks on the surface, first turn to eliminate cracked layer;

[0029] Pure Nb rods are used as electrode materials for EDM deposition to obtain NbC strengthened nanocrystalline coatings. During the deposition process, inert gas is used for protection. The specific process parameters of deposition are: output power 2000W, output voltage 250V, deposition rate 8min / cm 2 .

[0030] The workpiece obtained in the previous step is boronized by solid boronizing process, wherein the boronizing agent is LSB-II type boronizing agent, and the boronizing process parameters are: boronizing temperature 1100°C, boronizing holding time is 500min .

[0031] The composite gradient wear-resistant coating finally prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com