Cement firing system and automatic optimizing control system thereof

A control system and cement technology, applied in the furnace control device, furnace type, preheating cost, etc., to achieve the effect of improving economic efficiency, stabilizing quality and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

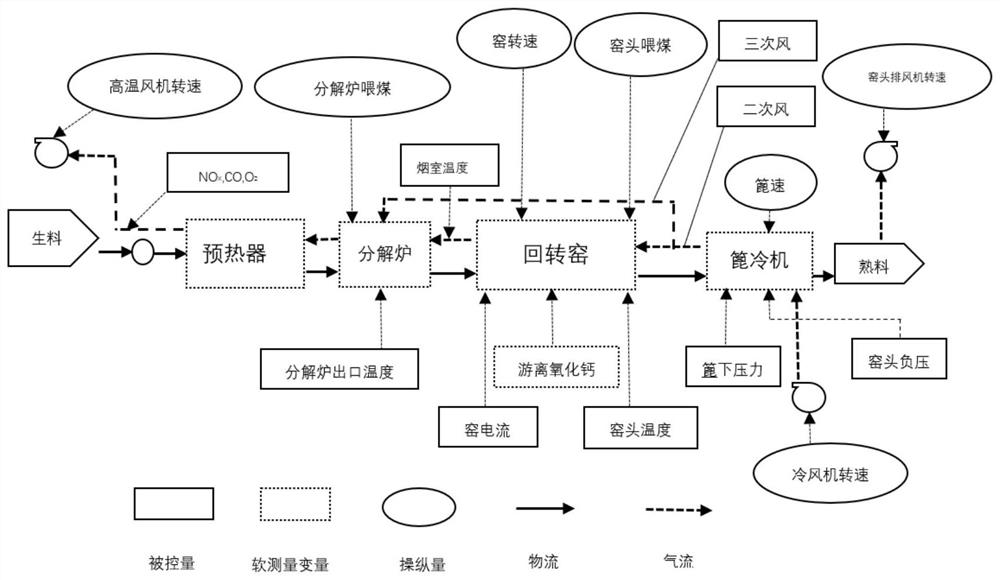

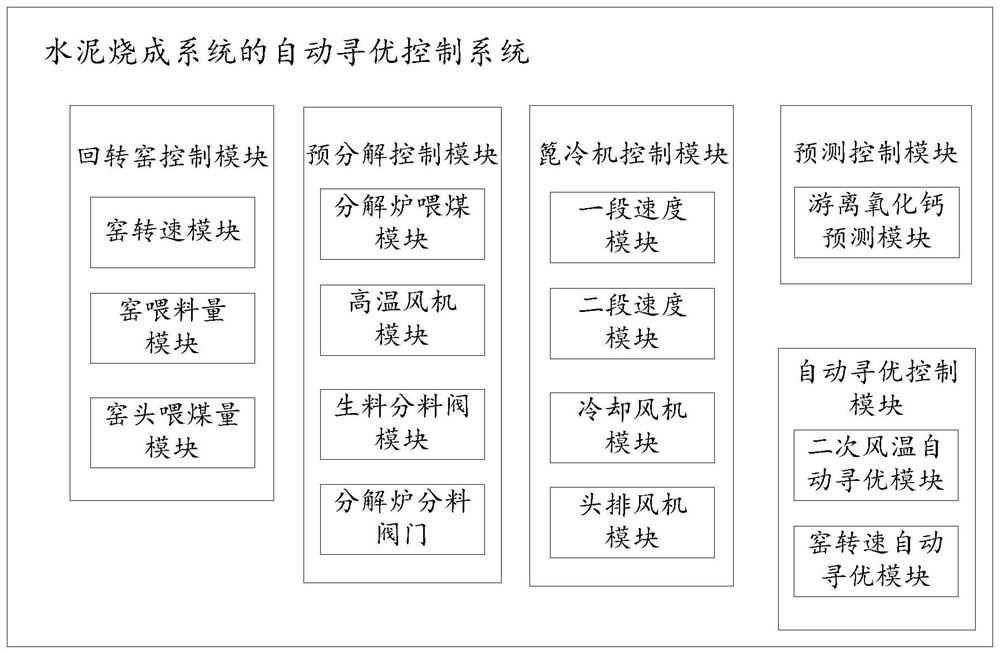

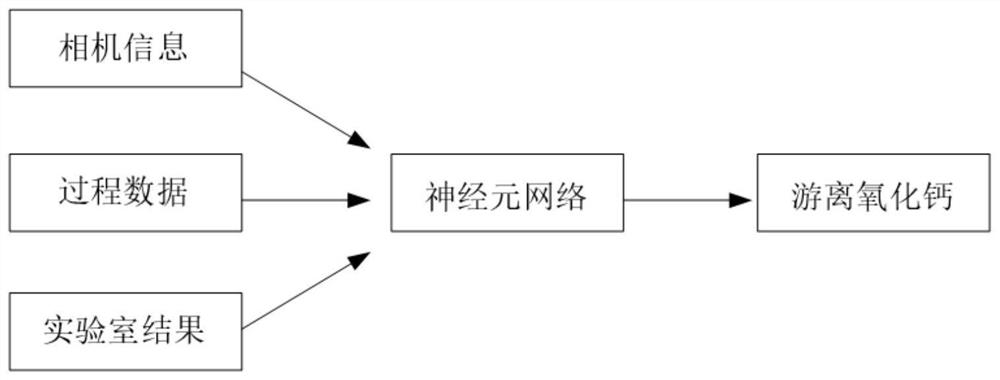

[0051] figure 1 It is the overall structure diagram of the automatic optimization control system of the cement firing system in an embodiment, as shown in the figure. A cement burning system includes a preheater, a decomposition furnace, a rotary kiln, and a grate cooler. After the raw meal enters the preheater for heating, it is sent to the decomposition furnace to decompose the raw meal into free oxidation at high temperature. Calcium generates cement clinker, which is output after being cooled by the grate cooler.

[0052] Among them, the raw meal is a material that is made of lime-based raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com