Integrated oxygen production system

An oxygen production system, an integrated technology, applied in oxygen production, specific gas purification/separation, oxygen/ozone/oxide/hydroxide, etc., can solve the problems of oxygen production system damage, inability to produce oxygen, and high manufacturing costs , to achieve the effect of reducing power consumption and noise level, facilitating overall maintenance and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples.

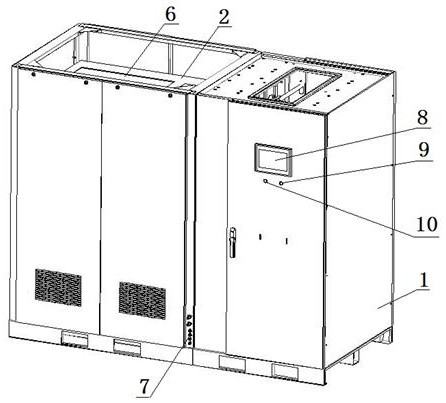

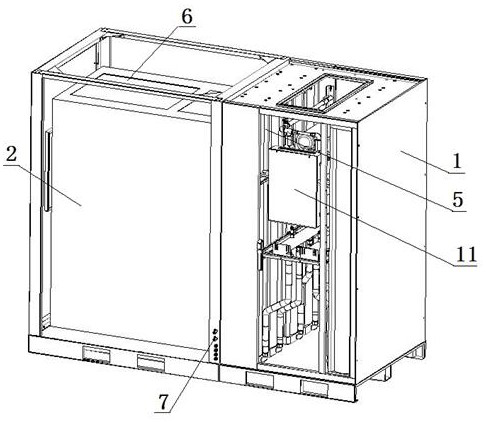

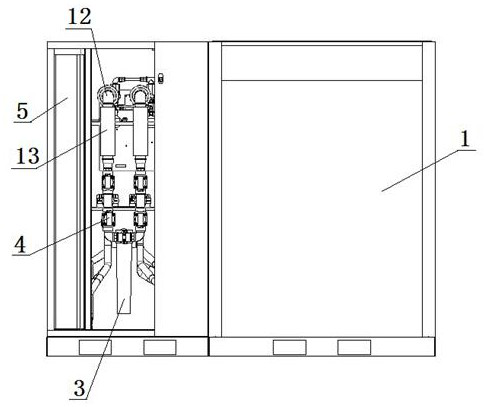

[0027] refer to Figure 1-4 , this embodiment provides an integrated integrated oxygen production system, the casing 1 can be disassembled into two parts left and right, one part of the casing is provided with an air compressor 2, and the other part of the casing is provided with an adsorption tower group 5, A secondary precision filter 3 and two groups of air control valves 4; the air compressor 2 is provided with an air inlet on the casing 1, and a cold dryer is provided inside the air compressor 2, and the output end of the air compressor 2 It is connected to the input end of the secondary precision filter 3, and the output end of the secondary precision filter 3 is connected to the input end of one group of air control valves 4, and the output end of the group of air co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com