Silane modified polycarboxylate superplasticizer, preparation method thereof, concrete admixture using superplasticizer, and preparation method of concrete admixture

A technology of concrete admixture and silane modification, which is applied in the fields of silane-modified polycarboxylate water reducer, concrete admixture, and chemical admixture. The admixture system is stable, maintains workability, and the effect of system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

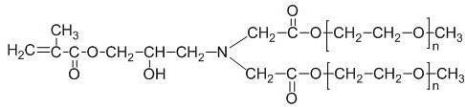

Image

Examples

Embodiment 1

[0059] 1. Silane-modified polycarboxylate water reducer and its preparation method

[0060] In this example, a silane-modified polycarboxylate water-reducer was prepared. The raw materials used include: polyoxyethylene ether 10%, acrylic acid 32%, γ-methacryloxypropyl trimethoxysilane 1.8% by mass percentage %, ammonium persulfate 0.35%, 3-mercaptoacetic acid 0.18%, and the balance is deionized water.

[0061] Concrete preparation method comprises the following steps:

[0062] (1) Mix 10% (mass percentage, the same below) polyoxyethylene ether with a small amount of deionized water, put it in a three-necked flask and place it in a water bath, stir and pre-dissolve the mixture at a temperature of 30°C, and set aside;

[0063] (2) Mix 0.35% initiator ammonium persulfate, 32% acrylic acid and deionized water to prepare material A; 0.18% chain transfer agent 3-mercaptoacetic acid and deionized water to prepare material B; 1.8% monomer γ-formazol Acryloyloxypropyltrimethoxysilan...

Embodiment 2

[0077] Others are the same as in Example 1, except that n=20.

Embodiment 3

[0079] Others are the same as in Example 1, except that n=50.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com