Composite packaging material and photovoltaic module packaged by same

A technology of encapsulation materials and polymer materials, applied in the field of photovoltaic modules, can solve problems such as low resistivity, long lamination cycle, and long POE curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0090]The preparation process and various manufacturing processes of the photovoltaic module may be known common manufacturing procedures of the photovoltaic module, and the embodiment of the present invention makes no special limitation on the preparation of the photovoltaic module. Exemplarily, the preparation process of the photovoltaic module can be:

[0091] (1) Cell laser slicing: Process the entire cell into slices according to the set specifications.

[0092] (2) Welding: Automatic string welding cuts, shapes and welds the welding materials into certain strings according to the set spacing requirements.

[0093] (3) Laying: Conventional laying of glass, composite packaging materials, backplane / glass, etc.

[0094] (4) Lamination: set the appropriate temperature and time to cross-link the film material.

[0095] (5) Frame curing.

[0096] (6) Power test and classification.

[0097] Based on the above description, it can be seen that the photovoltaic module provided ...

Embodiment 1

[0100] A composite packaging material includes improved polyimide and EVA materials, and the composite packaging adhesive film is prepared by co-extruding the improved polyimide and EVA materials. Wherein, improved polyimide comprises the raw material of following mass parts:

[0101] 70-80 parts of polyimide, 2-3 parts of polyperfluoroethylene propylene, 2 parts of fluorine-containing linear polyimide and 2-4 parts of tetramethyldisiloxane.

[0102] The edge body resistivity of the composite packaging material is 1.5-1.8×10 17 Ω·cm, the breakdown voltage strength is 80-100KV / mm.

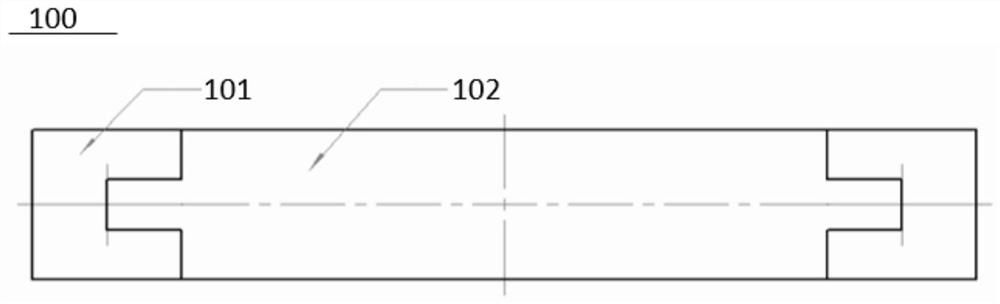

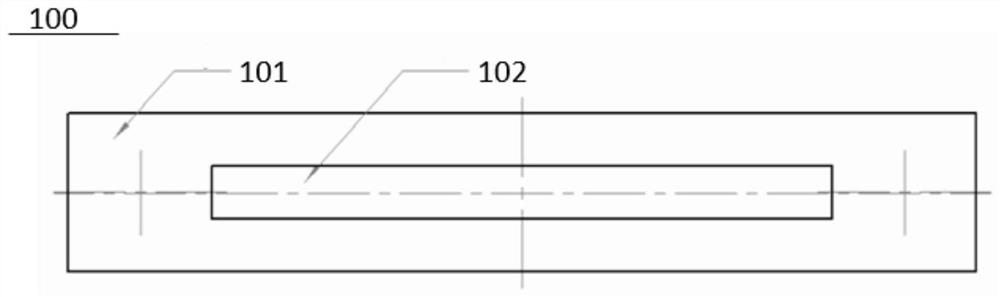

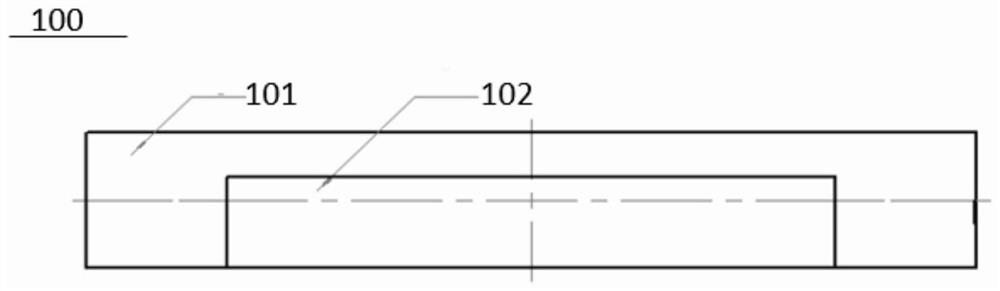

[0103] The improved polyimide in the composite packaging material has a width of 20-30mm and a thickness of 0.2mm; it can meet the requirement of shortening the blank width of the edge of the composite packaging adhesive film component glass and battery sheet from 15mm to 12mm, reducing component glass, Film material consumption reduces component weight by about 0.4%.

Embodiment 2

[0105] A composite packaging material includes improved polyimide and EVA materials, and the composite packaging adhesive film is prepared by co-extruding the improved polyimide and EVA materials. Wherein, improved polyimide comprises the raw material of following mass parts:

[0106] 80-92 parts of polyimide, 1-3 parts of polyperfluoroethylene propylene, 4-6 parts of fluorine-containing linear polyimide and 3-5 parts of tetramethyldisiloxane.

[0107] The edge body resistivity of the composite packaging material is 3.2-4.7×10 17 Ω·cm, the breakdown voltage strength is 120-180KV / mm.

[0108] The width of the improved polyimide in the composite packaging material is greater than the width of the internal EVA material, and the thickness is 0.1mm; it can meet the requirement of shortening the blank width of the composite packaging film module glass and the edge of the cell from 15mm to 10mm, reducing the component glass , Film material consumption, reduce component weight by ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com