Synergist for water-based drilling fluid, preparation method of synergist, water-based drilling fluid and application

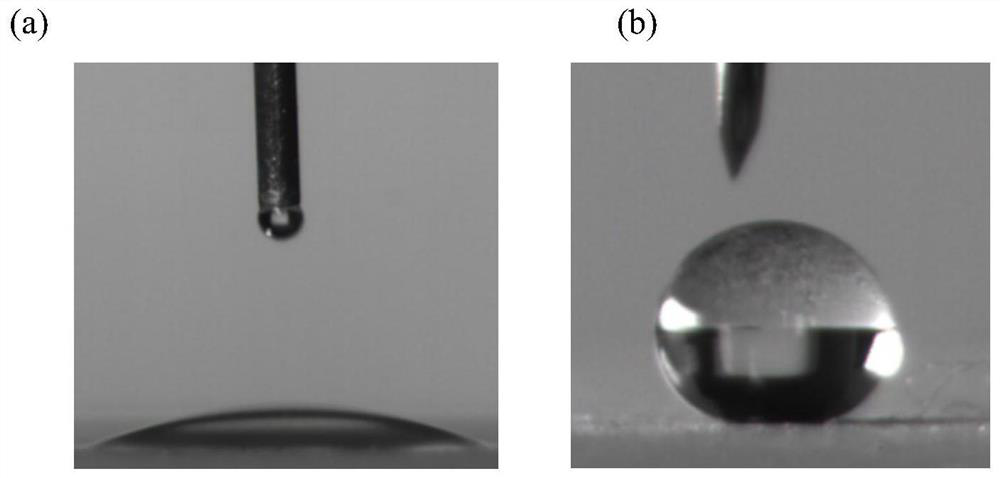

A technology of water-based drilling fluid and synergist, which is applied in wellbore/well components, chemical instruments and methods, earthwork drilling and production, etc. It can solve reservoir damage, wellbore instability, difficulty in drilling effective oil and gas layers, etc. problem, to achieve the effect of reducing pressure and free energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] An embodiment of the present invention also proposes a method for preparing a synergist, including the following steps,

[0040] 1) Mix didodecyldimethylammonium bromide with distilled water and ethanol, heat up to 65-75°C, add nano-silica, n-octyltriethoxysilane, and paraffin, and react to obtain surface modification. sexual products;

[0041] 2) Cool down the above-mentioned surface modified product, add sodium styrene sulfonate, allyl trimethyl ammonium chloride, disodium lauryl sulfosuccinate, propyl triethoxysilane, and heat up to 50-75 ℃, react to get synergist.

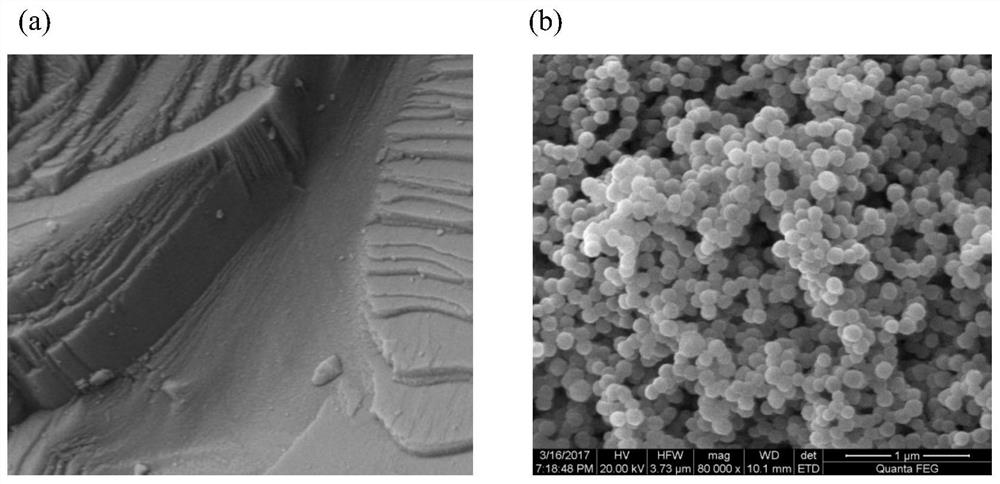

[0042] The synergist that the embodiment of the present invention proposes, at first, utilizes dodecyl dimethyl ammonium bromide, paraffin, n-octyltriethoxysilane to carry out surface modification to nano-scale silicon dioxide, and then, with Sodium styrene sulfonate, allyl trimethyl ammonium chloride, disodium lauryl sulfosuccinate, and propyl triethoxysilane are polymerized to obtain an ester emulsio...

Embodiment 1

[0068] Example 1 A kind of preparation method of synergist for water-based drilling fluid

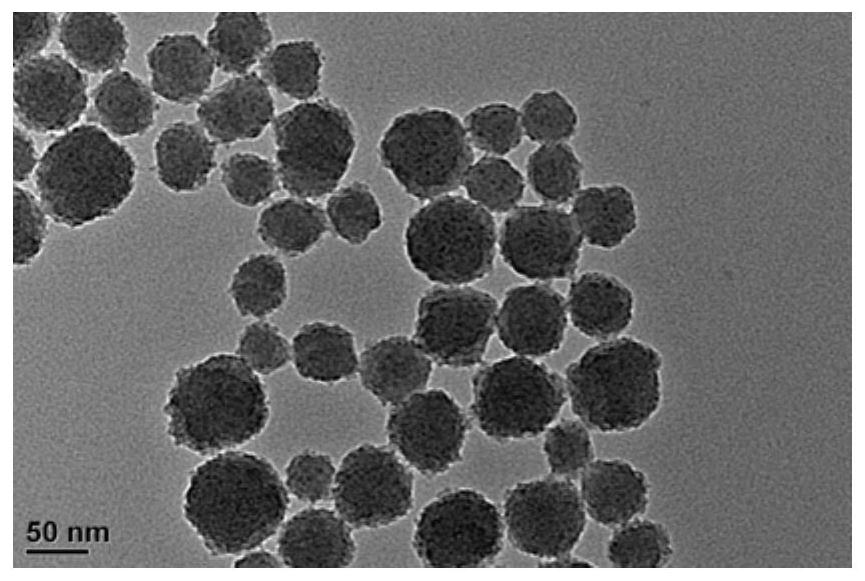

[0069] In the reaction kettle, add 30 parts of distilled water, 5 parts of ethanol, and 5 parts of didodecyldimethylammonium bromide, stir evenly, raise the temperature to 75°C, and add nano-SiO with a particle size of 100-500nm 2 15 parts, 10 parts of paraffin, 2 parts of n-octyltriethoxysilane, for SiO 2 Carry out surface modification for 2-3 hours, cool down to room temperature; add 20 parts of sodium styrene sulfonate, 10 parts of allyltrimethylammonium chloride, 1 part of disodium lauryl sulfosuccinate, propyl triethoxy 2 parts of base silane, stir evenly, raise the temperature to 50-75°C, and react for 8-16h to obtain the ester emulsion product.

Embodiment 2

[0070] Example 2 A kind of preparation method of synergist for water-based drilling fluid

[0071] Same as Example 1, except that there are 5 parts of n-octyltriethoxysilane and 5 parts of propyltriethoxysilane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com