Plating hanger and processing method for BGA packaged circuit module

A technology for encapsulating circuits and circuit modules, applied in printed circuits, printed circuit manufacturing, electrolytic components, etc., can solve the problems of nickel plating and gold plating solution waste, damage to the surface of potting body, incomplete coating, etc., to ensure reliability and Uniformity, convenient and precise positioning, and the effect of ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

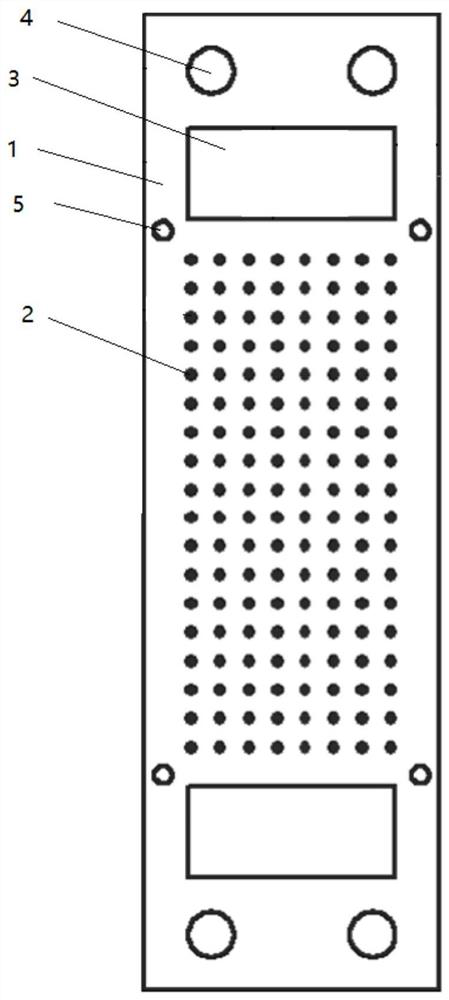

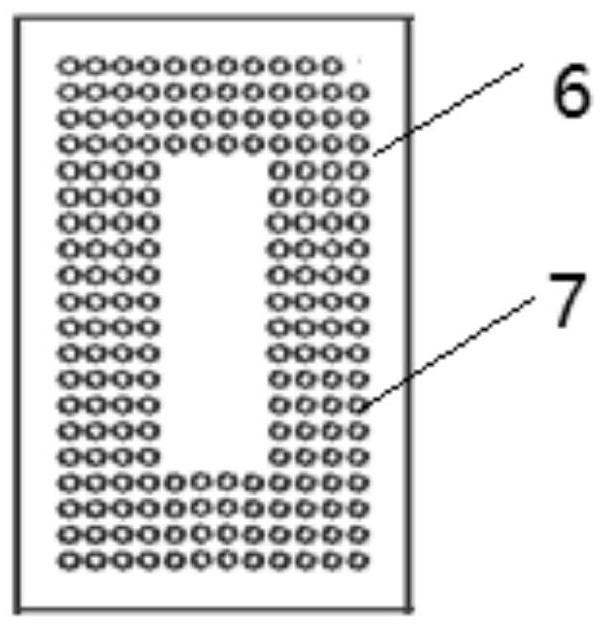

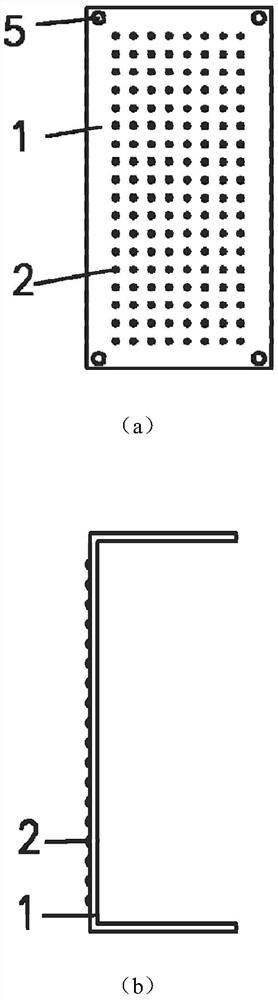

[0042] by figure 2 Taking the BGA package circuit module as an example, design the hanger:

[0043] 1. figure 2 The size of the BGA pad on the bottom board of the circuit module is 0.76mm, and the surface of the bottom board is coated with solder resist. Set the surface contact point at the corresponding position, the size of the contact point is 0.56mm (0.1mm smaller than one side of the pad), and select the first row and two columns, one row and 11 columns, 20 rows and two columns, and 20 rows and 11 columns of the BGA pad on the bottom board , the corresponding positions of the 4 pads are provided with alignment holes, the size of the alignment holes is 0.8mm (0.02mm larger than the single side of the pad), and the graphic design of the substrate processing is as follows: figure 1 ;

[0044] 2. Design the bending area on both sides of the alignment figure, the center of the bending area is designed to be hollowed out with a width of 2mm on both sides of the connecting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com