Preparation method and application of a patterned ultralight flexible self-supporting zinc electrode

A zinc-supporting, patterning technology, applied in the direction of electrode manufacturing, active material electrodes, negative electrodes, etc., can solve the problems of limiting the cycle life of devices and increasing the quality of devices, so as to inhibit volume expansion and dendrite growth, facilitate penetration, and mechanical good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Place the conductive ITO glass in ethanol and deionized water for 10-15 minutes;

[0025] (2) Spin-coat Ruihong photoresist on the ITO conductive surface obtained in step (1), first spin-coat at 500rpm for 10s, and then spin-coat at 800rpm for 25s;

[0026] (3) Place the ITO obtained in step (2) on a constant temperature plate for drying, the temperature of the constant temperature plate is 75° C., and the drying time is 60 minutes;

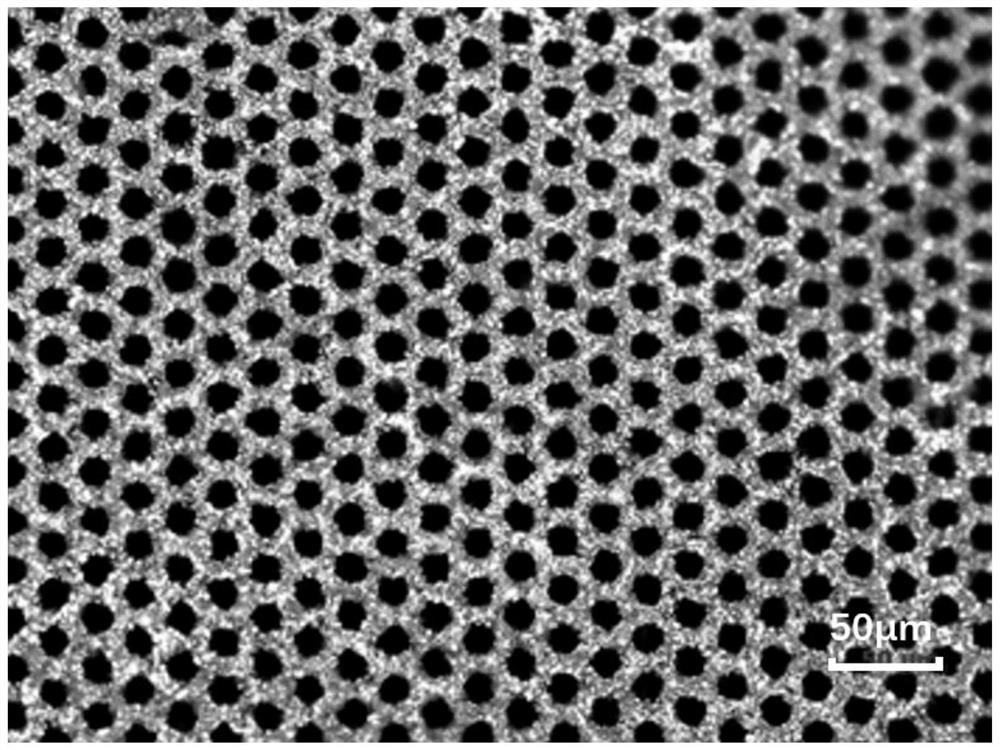

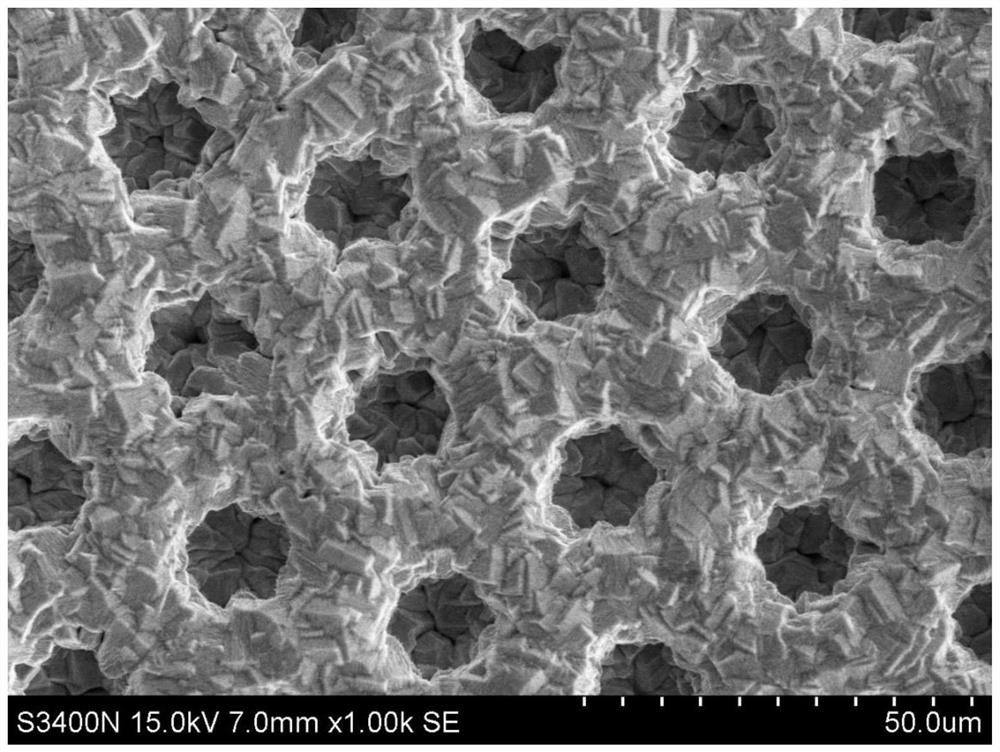

[0027] (4) After patterning and exposing the photoresist on the ITO obtained in step (3) for 28 seconds, use 0.5% sodium hydroxide to dissolve and clean it for 40 seconds to make a hard template;

[0028] (5) 11.4%wt of zinc sulfate heptahydrate and 15.4%wt of sodium sulfate and 0.5%wt of boric acid solution are dissolved in deionized water of 72.7%wt, configured into electroplating solution;

[0029] (6) Place the hard template obtained in step (4) in the electroplating solution obtained in step (5) and apply 25mA*cm -2 The constant...

Embodiment 2

[0033] (1) Place the graphite plate successively in ethanol and deionized water for 10-15min;

[0034] (2) Spin-coat Ruihong photoresist on the graphite plate obtained in step (1), first spin-coat with 600rpm for 10s, and then spin-coat for 30s with 800rpm;

[0035] (3) Place the graphite plate obtained in step (2) on a constant temperature plate for drying, the temperature of the constant temperature plate is 70° C., and the drying time is 60 minutes;

[0036] (4) Patterning and exposing the photoresist on the graphite plate obtained in step (3) for 15 seconds and then using 0.5% sodium hydroxide to dissolve and clean it for 26 seconds to make a hard template;

[0037] (5) 11.4%wt of zinc sulfate heptahydrate and 15.4%wt of sodium sulfate and 0.5%wt of boric acid solution are dissolved in 72.7%wt of deionized water, configured into electroplating solution;

[0038] (6) Place the hard template obtained in step (4) in the electroplating solution obtained in step (5) and apply ...

Embodiment 3

[0042] (1) Place AZO successively in ethanol and deionized water for 10-15min;

[0043] (2) Spin-coat Ruihong photoresist on the AZO conductive surface obtained in step (1), the speed of the homogenizer is 800rpm, and the time is 60s;

[0044] (3) Place the AZO obtained in step (2) on a constant temperature plate for drying. The constant temperature plate is first baked at 50°C for 30 minutes, and then at 75°C for 60 minutes;

[0045] (4) Patterning and exposing the photoresist on the AZO obtained in step (3) for 50 s and then dissolving and cleaning with 0.5% sodium hydroxide for 60 s to make a hard template;

[0046] (5) 11.4%wt of zinc sulfate heptahydrate and 15%wt of sodium sulfate and 0.9%wt of boric acid solution are dissolved in deionized water of 72.7%wt, configured into electroplating solution;

[0047] (6) Place the hard template obtained in step (4) in the electroplating solution obtained in step (5) and apply 25mA*cm -2 The constant current is electroplated to m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com