Waste gas treatment process for threonine production

A technology for waste gas treatment and threonine, which is applied in the field of threonine production, can solve the problems of incomplete exhaust gas treatment, reduced wind speed, narrow application area, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

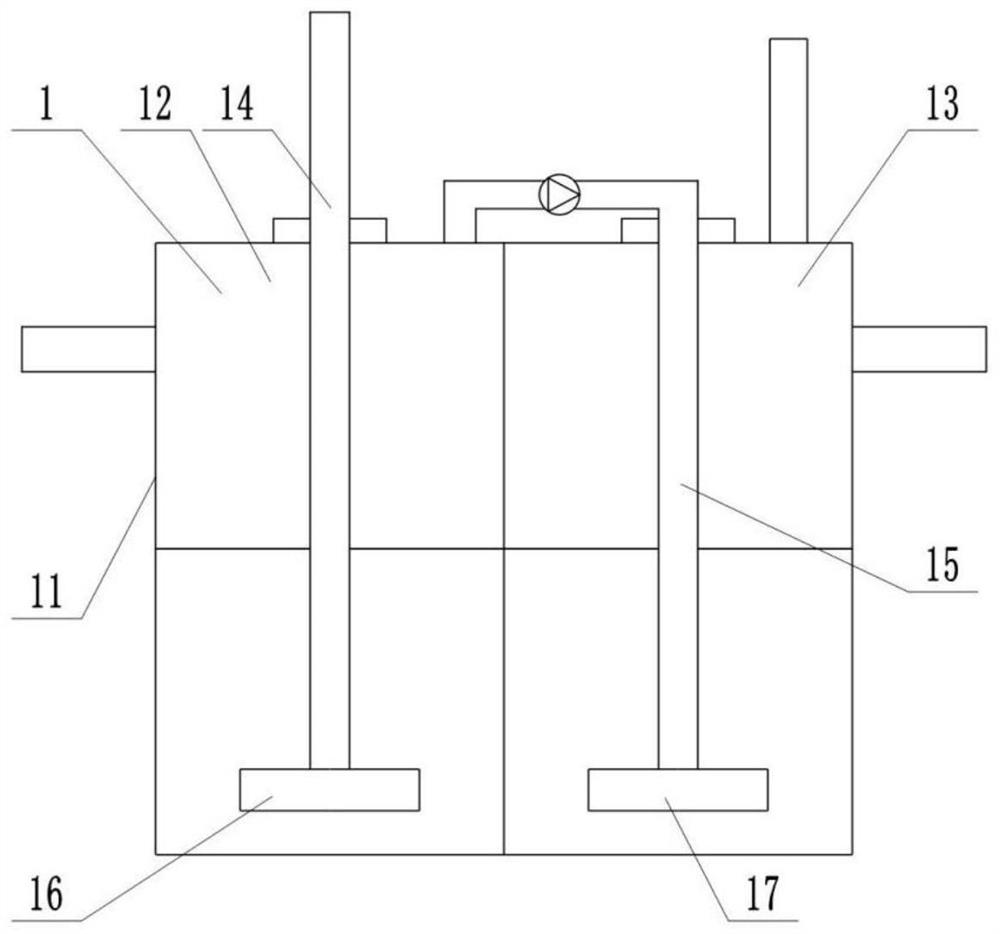

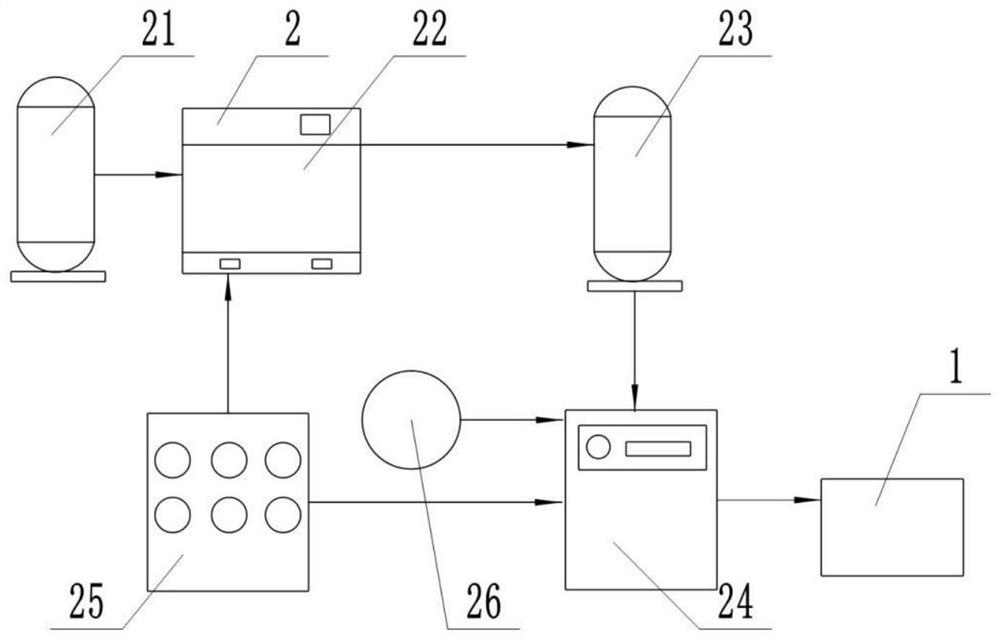

[0042] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

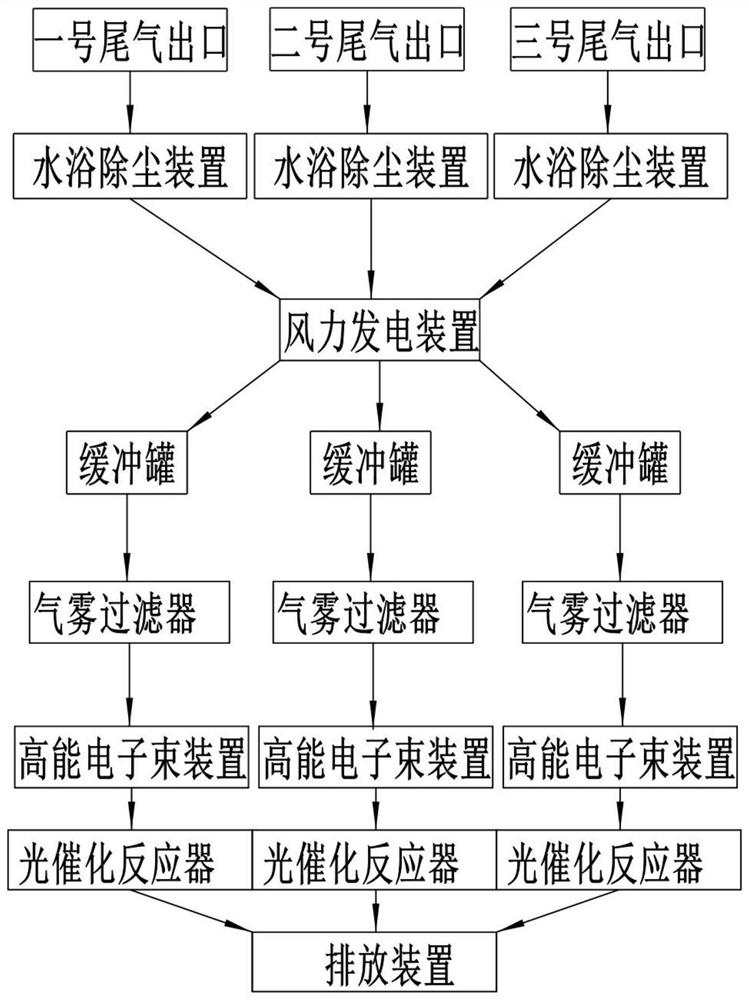

[0043] Such as Figure 1-7 Shown, a kind of waste gas treatment process for threonine production comprises steps as follows:

[0044] a Exhaust gas distribution

[0045] There are three sources of waste gas in the production process of threonine protein, which are granulation bed exhaust gas, fluidized bed exhaust gas and tank farm exhaust gas. There are three granulation beds, one fluidized bed and two evaporators in the threonine protein production workshop Feed tank, one zein receiving tank, two concentrate tanks, one effect CIP tank and one protein secondary condensation tank, the three granulation beds are respectively named No. 1 granulation bed and No. 2 granulation bed Bed and No. 3 granulation bed, two evaporative feeding tanks, one zein receiving tank, two concentrate tanks, one effect CIP tank and one protein secondary condensation tank are all t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap